Build List

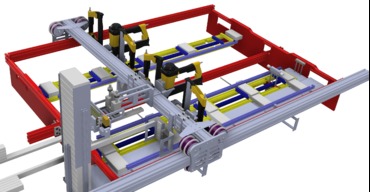

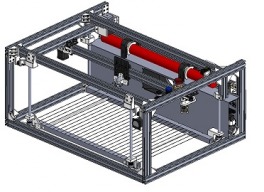

SMD Pick and place machine - Smoothieboard/OpenPnp

A dual head PNP machine that uses Openbuilds hardware, a Smoothieboard controller, dual camera vision, automatic/drag feeders, and OpenPnp.

Build Author

Ariel Yahni

Views

6645

Build Author

Ariel Yahni

Views

6645

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

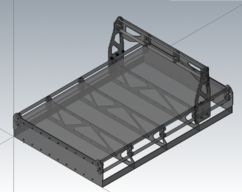

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

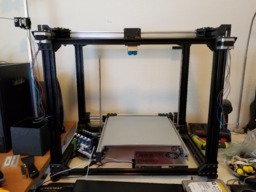

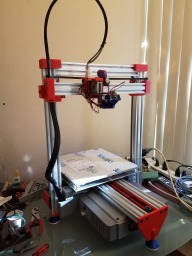

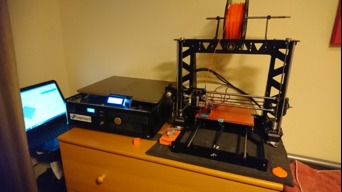

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Build Author

JerwanDavis

Views

6084

Build Author

JerwanDavis

Views

6084

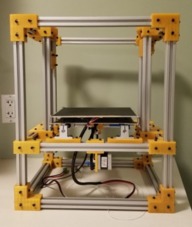

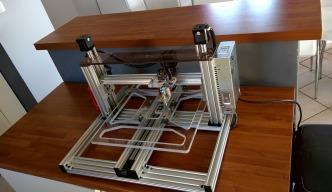

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

Bikes and Beer

Views

4873

Build Author

Bikes and Beer

Views

4873

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

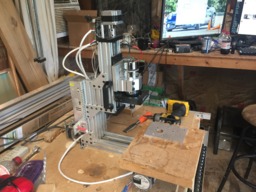

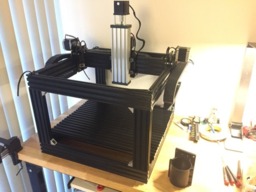

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

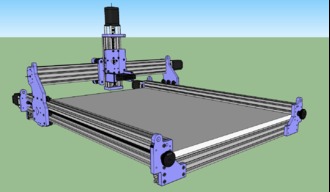

LimpyCNC

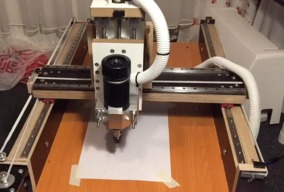

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

CharlieShimota

Views

16237

Build Author

CharlieShimota

Views

16237

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Butterfly 3DP V 1.0

tronxy x3 like

Build Author

holographic

Views

7940

Build Author

holographic

Views

7940

Laser DIY

How i construct and create my DIY Co2 Laser cutter and engraving mashine. details will follow

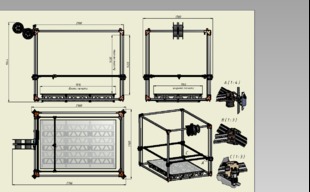

Large 3D Printer 5ft by 5ft print bed

New ultra large 3D Printer design. I'm calling it the AutoCrafter

Build Author

patnap71

Views

6911

Build Author

patnap71

Views

6911

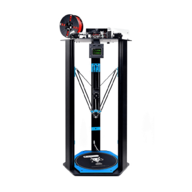

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

OoozNest WorkBee

A Journey on the WorkBee Build...

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Build Author

Christian James

Views

9999

Build Author

Christian James

Views

9999

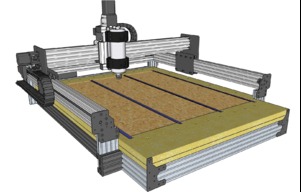

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

John Bolduc

Views

5972

Build Author

John Bolduc

Views

5972

SG Duet Delta

This my version of a large no corners cut Delta.

Build Author

Joe Young

Views

5919

Build Author

Joe Young

Views

5919

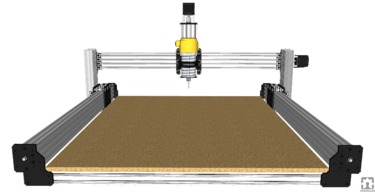

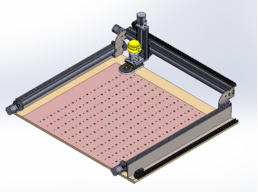

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

TurfnSurf

Views

7155

Build Author

TurfnSurf

Views

7155

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

Build Author

pedrofernandez

Views

15287

Build Author

pedrofernandez

Views

15287

The Franken Forty

This is a K40 machine conversion!!

Big a** printer

In-progress 500x500x1800

Build Author

Jacob Lotter

Views

6018

Build Author

Jacob Lotter

Views

6018

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

Rob Taylor

Views

20256

Build Author

Rob Taylor

Views

20256

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Build Author

Lumberjack Engineering

Views

20201

Build Author

Lumberjack Engineering

Views

20201

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Router for speargun hobby

First router build for speargun fabrication

Build Author

pedrofernandez

Views

10040

Build Author

pedrofernandez

Views

10040

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Build Author

MrMojoRisin

Views

7606

Build Author

MrMojoRisin

Views

7606

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Build Author

Savvas

Views

18764

Build Author

Savvas

Views

18764

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

Connor Mckeown

Views

6419

Build Author

Connor Mckeown

Views

6419

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Liam Dahler

Views

6552

Build Author

Liam Dahler

Views

6552

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

Sonny Lowe

Views

34796

Build Author

Sonny Lowe

Views

34796

MakerSL MSL-5 Cantilevered 3D Printer

This is a simple cantilevered 3D Printer. It is designed around the OB V-Slot linear rails. I am trying to simplify this as much as possible, all rails will be 250mm long and only one will require cutting (it will be cut in half). The printer will use all OB wheels and gantry plates where applicable, all other plates can be either Laser Cut or 3D Printed (files will be provided for both). I am not set on electronic as of yet, but plan to use a single control board...no Arduino/Ramps control.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

rob4cnc

Views

4034

Build Author

rob4cnc

Views

4034

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Robert E. Nee

Views

17505

Build Author

Robert E. Nee

Views

17505

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

SCYBUCK

Views

5137

Build Author

SCYBUCK

Views

5137

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Michael.M

Views

9690

Build Author

Michael.M

Views

9690

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

MikieLikesIt

Views

8267

Build Author

MikieLikesIt

Views

8267

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

My Little Mashup

A mixed drive, PI Controlled machine

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

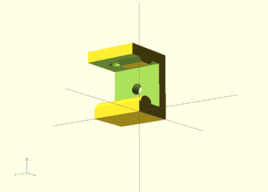

DIN 35mm -like quick clip for 20mm extrusion

A half baked idea for mounting electrics and electronics using a 35mm-DIN-rail-like mounting.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Build Author

Kyo

Views

6534

Build Author

Kyo

Views

6534

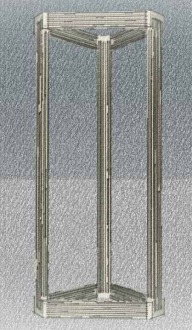

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

mytechno3d

Views

28510

Build Author

mytechno3d

Views

28510

Maximus Evolution (Still another XL 3D Printer )

Maximus Evolution : 380mm x 400mm XL 3D Printer

Galvos

3d printable galvos

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Nicademus

Views

9583

Build Author

Nicademus

Views

9583

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

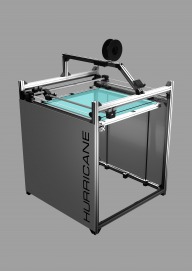

Hurricane - Large 80cm x 80cm x 80cm cm build space project

Huge - Fast - Affordable

Build Author

Carl Siren

Views

7662

Build Author

Carl Siren

Views

7662

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Colin Russon

Views

9439

Build Author

Colin Russon

Views

9439

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Sword66

Views

14007

Build Author

Sword66

Views

14007

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Sprags

Views

2746

Build Author

Sprags

Views

2746

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

jpjoshua

Views

13436

Build Author

jpjoshua

Views

13436

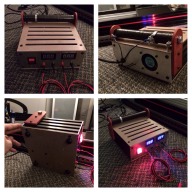

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Laser engraver

Just a little light duty laser engraver.

Big-X Minimill

Minimill bundle, but with an extended X Axis

V-Slot MAME cabinet

A minimalist MAME "cabinet" made from extrusion.

Build Author

TurfnSurf

Views

6220

Build Author

TurfnSurf

Views

6220

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

DIY anodizing power supply

How to make your own anodizing power supply on a budget

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Build Author

Hussein Dermay

Views

6524

Build Author

Hussein Dermay

Views

6524

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

Build Author

Axnfell

Views

3106

Build Author

Axnfell

Views

3106

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Janis93

Views

15720

Build Author

Janis93

Views

15720

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

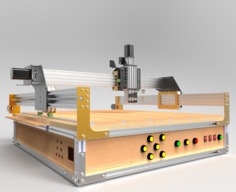

Something a Tad different

Future CNC router kit design

Build Author

Gooshpoo

Views

9347

Build Author

Gooshpoo

Views

9347

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

h3rb

Views

5741

Build Author

h3rb

Views

5741

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Weldsmith

Views

7729

Build Author

Weldsmith

Views

7729

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.