CNC ROUTER BUILDS

Build Author

Quentin Karmark

Views

9459

Build Author

Quentin Karmark

Views

9459

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

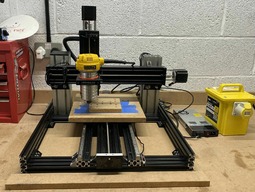

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Build Author

Shaun Weitzel

Views

7509

Build Author

Shaun Weitzel

Views

7509

OpenBuilds Lead 1515

First build of a Lead 1515!

Sphinx 66

A Sphinx Linear rail build (600mm x 600mm) hence the title Sphinx66. Plates supplied by Chris Laidlaw. Linear rails used MGN15

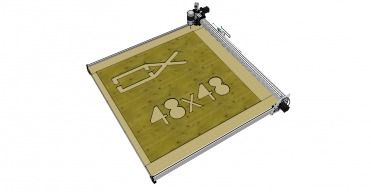

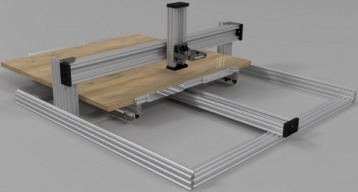

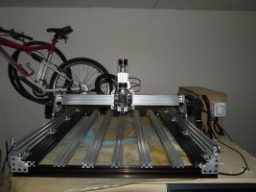

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

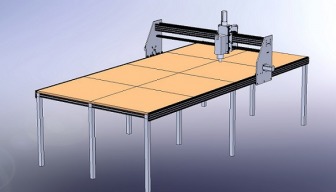

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

The Buffalo

OX 1500 x 1000 mm

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Build Author

Kermareg

Views

17368

Build Author

Kermareg

Views

17368

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

Steve hope

Views

19225

Build Author

Steve hope

Views

19225

8x4 CNC build

Routy cnc upgrade.

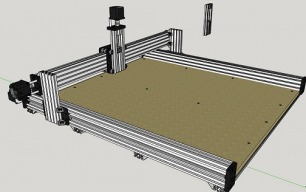

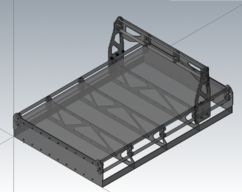

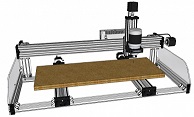

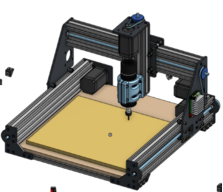

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

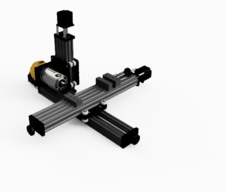

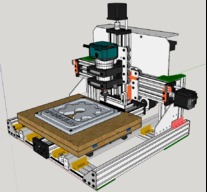

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

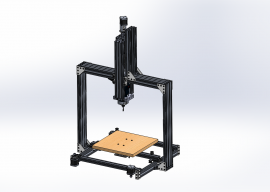

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

motopreserve

Views

9099

Build Author

motopreserve

Views

9099

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

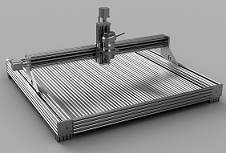

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Laurence Carroll

Views

10971

Build Author

Laurence Carroll

Views

10971

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Jesse Jenkins

Views

9419

Build Author

Jesse Jenkins

Views

9419

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Neptunes Guitars

Views

8530

Build Author

Neptunes Guitars

Views

8530

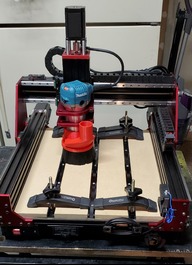

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

Textile machine bearing structures CNC engraving machine

With the textile machine bearing feel better strength, better durability 用纺织机轴承感觉强度要好一些,耐用性更好

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Build Author

Maxime Favre

Views

9537

Build Author

Maxime Favre

Views

9537

SmoothiebrainZ CBeam Machine

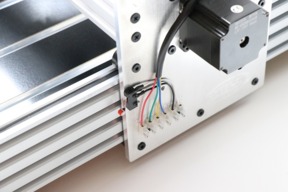

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

CNC Planning

Reusing parts to build a CNC - planning stage

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Build Author

Lindsey Lewis

Views

8202

Build Author

Lindsey Lewis

Views

8202

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

Andre Cooke

Views

17614

Build Author

Andre Cooke

Views

17614

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

ShockingTops

Views

4506

Build Author

ShockingTops

Views

4506

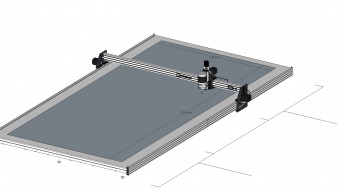

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

spark2

Views

5700

Build Author

spark2

Views

5700

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Something a Tad different

Future CNC router kit design

Build Author

Axnfell

Views

3106

Build Author

Axnfell

Views

3106

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Brandon Satterfield

Views

7719

Build Author

Brandon Satterfield

Views

7719

SMW3D OX

The SMW3D OX, original other than a lot of learning!

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

C-CNC

Views

16250

Build Author

C-CNC

Views

16250

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

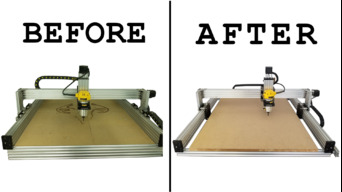

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

Build Author

msdosfx

Views

6170

Build Author

msdosfx

Views

6170

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

Build Author

RV6APilot

Views

4241

Build Author

RV6APilot

Views

4241

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Build Author

tmadrms

Views

7735

Build Author

tmadrms

Views

7735

C-Beam Mods

C-beam machine mods.

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Build Author

Wes Dwight

Views

7766

Build Author

Wes Dwight

Views

7766

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

Stokrotka74

Views

6952

Build Author

Stokrotka74

Views

6952

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Workbee with less irritations

My workbee build with some add ons

Black gear 1500X3000

My cnc update and rebuild.

Gauss Probe Machine

Standard build with high Z using a Gauss probe instead of a router.

KillerBee 1515 customized

Killerbee 1515 with modifications.

Build Author

EvanH

Views

4898

Build Author

EvanH

Views

4898

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

Build Author

Colin Russon

Views

8710

Build Author

Colin Russon

Views

8710

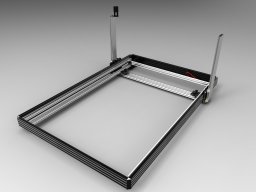

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

spunks.cam

Design of a multifunctional CNC machine.

Build Author

richthorn

Views

8267

Build Author

richthorn

Views

8267

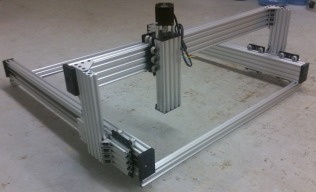

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

DiggerJ

Views

8785

Build Author

DiggerJ

Views

8785

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

d0rk1e

Views

7781

Build Author

d0rk1e

Views

7781

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Build Author

Joey Selzler

Views

13558

Build Author

Joey Selzler

Views

13558

My JGro CNC becomes an OpenBuild Project

This is the story of my progression from the JGRO cnc router design to using the OpenBuild system. In the process I think I have learned some things about cnc routers and the accuracy required to make a good build.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

Larry_AK

Views

10281

Build Author

Larry_AK

Views

10281

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

Custom OX Build

Inspired by the original OX by Mark Carew, this is my Custom OX. Many small changes, additions, and upgrades. Build is in progress and this post will be updated regularly with photos. Enjoy!

Build Author

ymilord

Views

19455

Build Author

ymilord

Views

19455

Small Portable PCB CNC Machine (CoreXY)

This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done.

Viking OX

My OX cnc upgrade.

Apple Crate CNC

Low cost, apple crate framed CNC.

OX 1000mm Y Axis Upgrade

Expands y-axis to 1000mm. 1/2 day build.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

Build Author

mikev

Views

8597

Build Author

mikev

Views

8597

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

signzonepr

Views

13041

Build Author

signzonepr

Views

13041

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

Hisha

Views

5062

Build Author

Hisha

Views

5062

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Build Author

Carl van Heezik

Views

8456

Build Author

Carl van Heezik

Views

8456

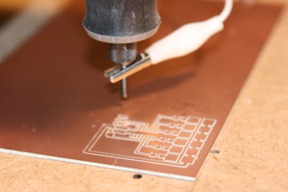

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

CandlerCustoms

Views

5569

Build Author

CandlerCustoms

Views

5569

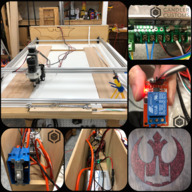

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Camvec

Views

6278

Build Author

Camvec

Views

6278

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

TurfnSurf

Views

6220

Build Author

TurfnSurf

Views

6220

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

crnrstndes

Views

4245

Build Author

crnrstndes

Views

4245

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

rob4cnc

Views

4034

Build Author

rob4cnc

Views

4034

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Craig Hollabaugh

Views

4901

Build Author

Craig Hollabaugh

Views

4901

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Christian James

Views

9999

Build Author

Christian James

Views

9999

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Jay Almers

Views

8042

Build Author

Jay Almers

Views

8042

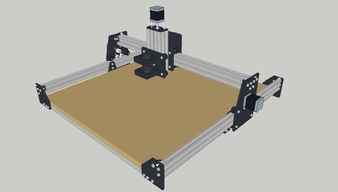

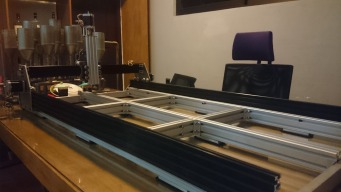

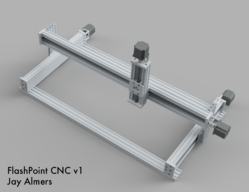

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.