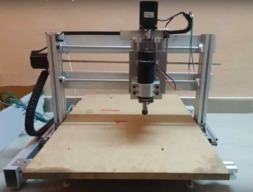

Cartesian Style CNC

Build Author

ymilord

Views

12740

Build Author

ymilord

Views

12740

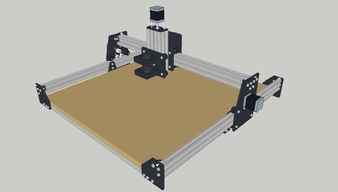

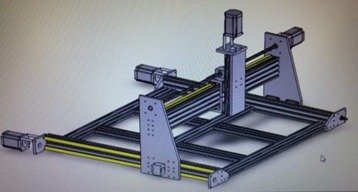

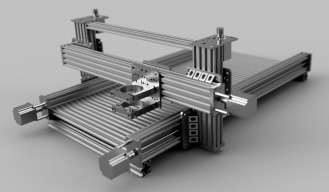

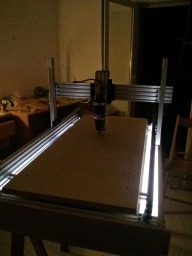

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

My Ox

What I want to build is a unit to: rout wood, plastic and occasional aluminium . to be able to swap cutters. i.e. drragknife, laser, router, drill

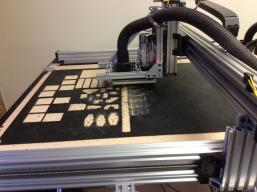

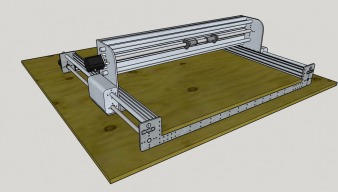

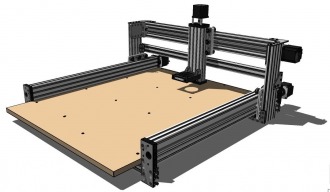

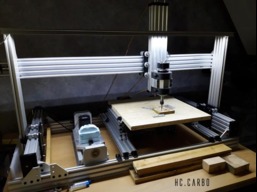

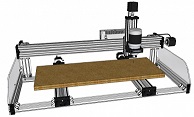

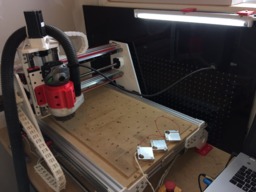

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Build Author

inhan

Views

12608

Build Author

inhan

Views

12608

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12577

Build Author

AndersFaust

Views

12577

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

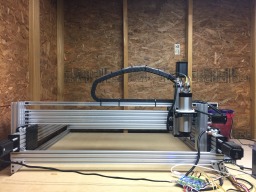

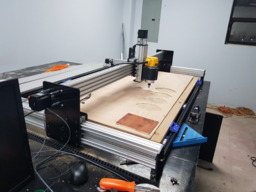

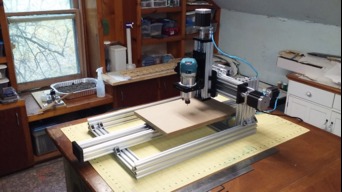

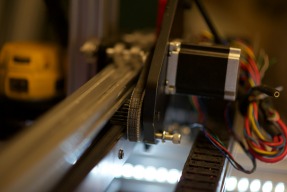

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

Build Author

GDanger117

Views

12379

Build Author

GDanger117

Views

12379

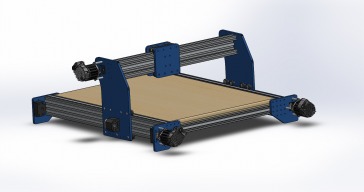

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Matt Nelson

Views

12334

Build Author

Matt Nelson

Views

12334

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

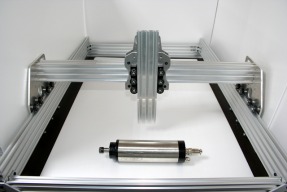

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

Build Author

Scott Martinez

Views

12212

Build Author

Scott Martinez

Views

12212

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

pedrofernandez

Views

12192

Build Author

pedrofernandez

Views

12192

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

SandeepsCNC

Views

12184

Build Author

SandeepsCNC

Views

12184

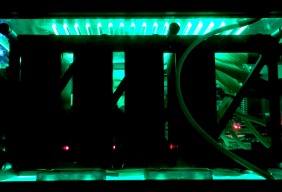

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

Promoveo Study Builds

Promoteo Build

Build Author

reef

Views

12031

Build Author

reef

Views

12031

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

Andreas Bockert

Views

12027

Build Author

Andreas Bockert

Views

12027

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

evil2002usna

Views

11580

Build Author

evil2002usna

Views

11580

Evil Ox

Cheap Ballscrew Ox CNC Router.

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

Ooznest OX CNC Build

Ooznest OX CNC build

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Build Author

Mike Campbell

Views

11149

Build Author

Mike Campbell

Views

11149

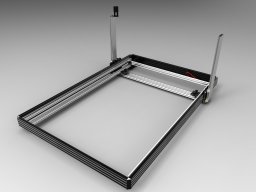

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Bear

Views

11068

Build Author

Bear

Views

11068

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

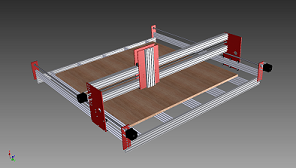

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

Laurence Carroll

Views

10976

Build Author

Laurence Carroll

Views

10976

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

Build Author

CNCGear

Views

10672

Build Author

CNCGear

Views

10672

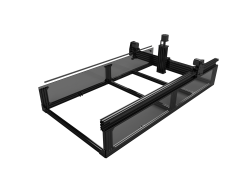

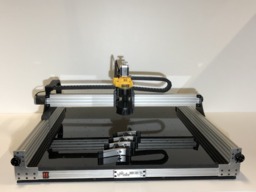

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Build Author

StrictlyScale

Views

10499

Build Author

StrictlyScale

Views

10499

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

Lasersc

Views

10477

Build Author

Lasersc

Views

10477

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

Build Author

Pendragon

Views

10329

Build Author

Pendragon

Views

10329

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Viking OX

My OX cnc upgrade.

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

Frank Del Favero

Views

9754

Build Author

Frank Del Favero

Views

9754

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

Build Author

Michael.M

Views

9702

Build Author

Michael.M

Views

9702

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

OX Build

Standard OX Build

Build Author

mathom713

Views

9639

Build Author

mathom713

Views

9639

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

OX

My build of the OX kit from SMW3D.com

Build Author

Maxime Favre

Views

9538

Build Author

Maxime Favre

Views

9538

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

Christer Langley

Views

9461

Build Author

Christer Langley

Views

9461

CNC-Solutions Build

My first Build with V-slot

Build Author

Jesse Jenkins

Views

9423

Build Author

Jesse Jenkins

Views

9423

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Rwetzler

Views

9400

Build Author

Rwetzler

Views

9400

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

zann68

Views

9334

Build Author

zann68

Views

9334

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Huub65

Views

9321

Build Author

Huub65

Views

9321

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Pol Feliu

Views

9281

Build Author

Pol Feliu

Views

9281

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

HuguesP

Views

9270

Build Author

HuguesP

Views

9270

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

Justin Butler

Views

9247

Build Author

Justin Butler

Views

9247

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Build Author

Tucstrlly

Views

9098

Build Author

Tucstrlly

Views

9098

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

evildean

Views

8916

Build Author

evildean

Views

8916

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Build Author

Hisha

Views

8884

Build Author

Hisha

Views

8884

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

DiggerJ

Views

8795

Build Author

DiggerJ

Views

8795

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Our OX CNC Router Project

Our version of the OX, a Cartesian CNC Router Build. 1,500 mm Y-Axis, 1,000 mm X-Axis, 300 mm Z-Axis - Lots of Fun!

Build Author

Colin Russon

Views

8715

Build Author

Colin Russon

Views

8715

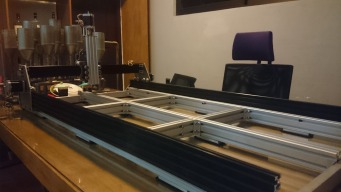

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

Build Author

mikev

Views

8603

Build Author

mikev

Views

8603

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Joe F

Views

8530

Build Author

Joe F

Views

8530

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

Kenneth Witthuhn

Views

8511

Build Author

Kenneth Witthuhn

Views

8511

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Schematix OX metal build

OX metal build from an noob

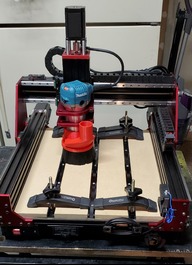

Desktop CNC

A desktop Cartesian CNC router

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

MikieLikesIt

Views

8270

Build Author

MikieLikesIt

Views

8270

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

richthorn

Views

8268

Build Author

richthorn

Views

8268

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

dmasters

Views

8249

Build Author

dmasters

Views

8249

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Julius

Views

8216

Build Author

Julius

Views

8216

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

Jay Almers

Views

8058

Build Author

Jay Almers

Views

8058

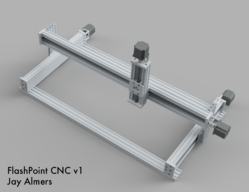

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

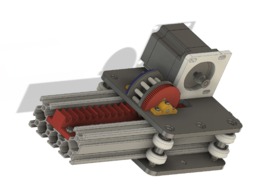

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

Build Author

d0rk1e

Views

7785

Build Author

d0rk1e

Views

7785

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

Build Author

Wes Dwight

Views

7772

Build Author

Wes Dwight

Views

7772

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Build Author

OffAxis

Views

7759

Build Author

OffAxis

Views

7759

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

tmadrms

Views

7746

Build Author

tmadrms

Views

7746

C-Beam Mods

C-beam machine mods.

Build Author

Weldsmith

Views

7737

Build Author

Weldsmith

Views

7737

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Build Author

Corey Corbin

Views

7634

Build Author

Corey Corbin

Views

7634

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.