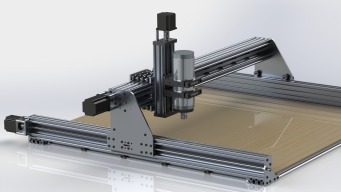

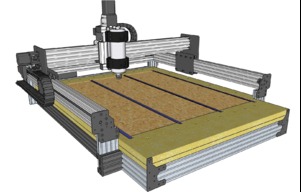

Cartesian Style CNC

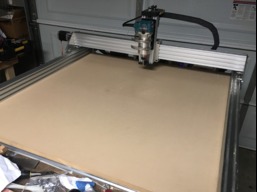

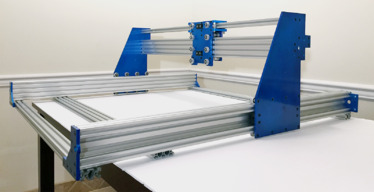

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

Apothus

Views

22517

Build Author

Apothus

Views

22517

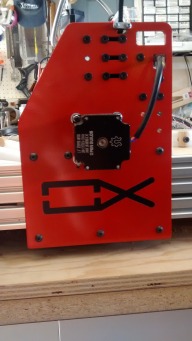

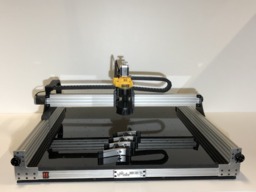

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Kenneth Witthuhn

Views

8511

Build Author

Kenneth Witthuhn

Views

8511

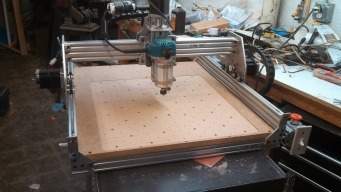

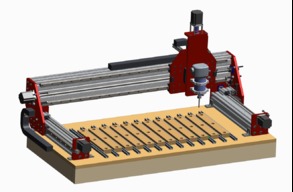

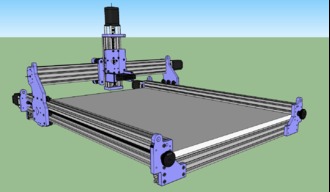

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

Yosmany325

Views

2440

Build Author

Yosmany325

Views

2440

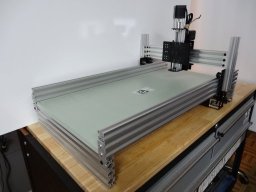

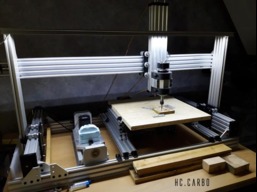

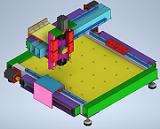

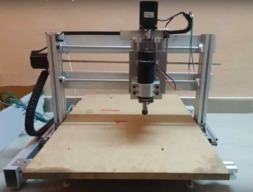

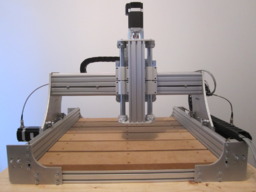

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Build Author

GinoTheCop

Views

14636

Build Author

GinoTheCop

Views

14636

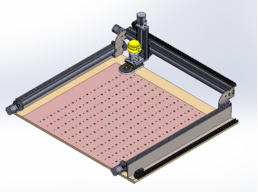

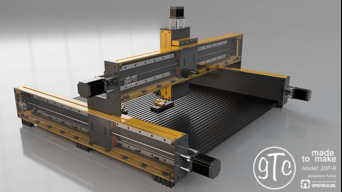

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

Andreas Bockert

Views

12027

Build Author

Andreas Bockert

Views

12027

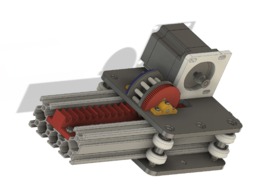

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

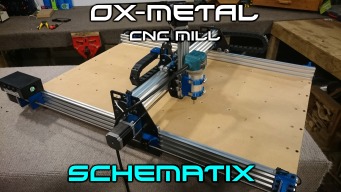

Schematix

Views

158171

Build Author

Schematix

Views

158171

OX-Metal CNC Router Mill

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

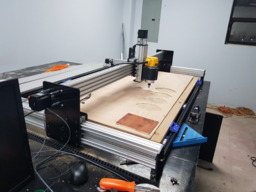

Cnc Router 3000 x 1000 mm

In progress

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Build Author

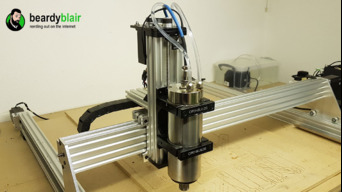

beardyblair

Views

25316

Build Author

beardyblair

Views

25316

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

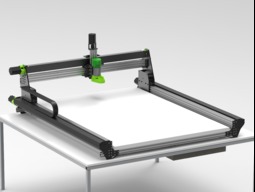

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

Build Author

SandeepsCNC

Views

12184

Build Author

SandeepsCNC

Views

12184

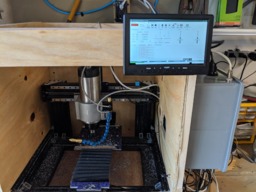

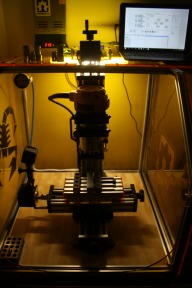

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

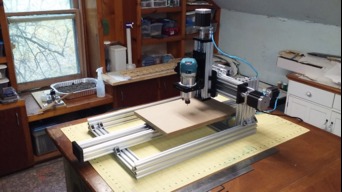

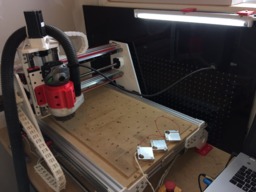

Aluminum OX build with some modifications

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!

ROUTY CNC Router (V-Slot Belt & Pinion)

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

Build Author

Forestbird Originals

Views

5502

Build Author

Forestbird Originals

Views

5502

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Build Author

HuguesP

Views

9270

Build Author

HuguesP

Views

9270

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

DaleShaw

Views

4489

Build Author

DaleShaw

Views

4489

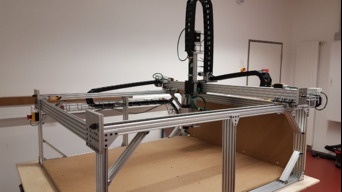

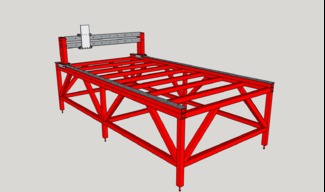

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Build Author

Neil Scott

Views

3282

Build Author

Neil Scott

Views

3282

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

SecretSpy711

Views

22613

Build Author

SecretSpy711

Views

22613

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

Fábio Pires

Views

7068

Build Author

Fábio Pires

Views

7068

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

tmadrms

Views

7746

Build Author

tmadrms

Views

7746

C-Beam Mods

C-beam machine mods.

Build Author

Craig Hollabaugh

Views

4910

Build Author

Craig Hollabaugh

Views

4910

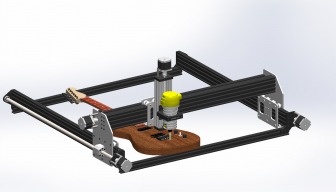

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

reef

Views

12031

Build Author

reef

Views

12031

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

Lasersc

Views

10477

Build Author

Lasersc

Views

10477

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

viktop

Views

18612

Build Author

viktop

Views

18612

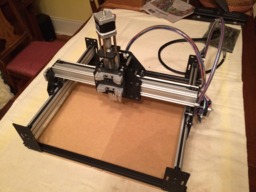

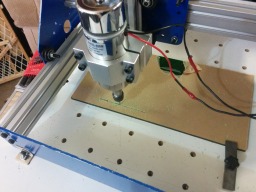

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

roadss

Views

26048

Build Author

roadss

Views

26048

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

75x75

Simple cnc with 5mm steel plates.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

msdosfx

Views

6178

Build Author

msdosfx

Views

6178

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

KronBjorn

Views

4480

Build Author

KronBjorn

Views

4480

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

RobFromLDMS

Views

5275

Build Author

RobFromLDMS

Views

5275

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

RV6APilot

Views

4244

Build Author

RV6APilot

Views

4244

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

Stan Howe

Views

3360

Build Author

Stan Howe

Views

3360

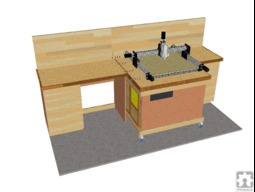

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

MarkM_NJ

Views

20011

Build Author

MarkM_NJ

Views

20011

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Cortellini

Views

5609

Build Author

Cortellini

Views

5609

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Bikes and Beer

Views

4884

Build Author

Bikes and Beer

Views

4884

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

CharlieShimota

Views

16243

Build Author

CharlieShimota

Views

16243

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

TurfnSurf

Views

7157

Build Author

TurfnSurf

Views

7157

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

joetemus

Views

6862

Build Author

joetemus

Views

6862

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Brokkr CNC 2.0

1M C-beam xy variant

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

My Shapeoko Router build

I built this as it is a small portable design.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

rob4cnc

Views

4036

Build Author

rob4cnc

Views

4036

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

SCYBUCK

Views

5140

Build Author

SCYBUCK

Views

5140

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Michael.M

Views

9702

Build Author

Michael.M

Views

9702

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

MikieLikesIt

Views

8270

Build Author

MikieLikesIt

Views

8270

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

Savvas

Views

14434

Build Author

Savvas

Views

14434

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Jones

Views

4016

Build Author

Jones

Views

4016

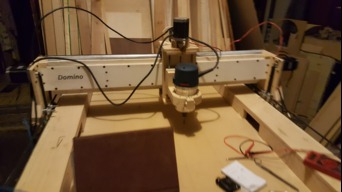

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

My Little Mashup

A mixed drive, PI Controlled machine

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

pedrofernandez

Views

12192

Build Author

pedrofernandez

Views

12192

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Gary Caruso

Views

24927

Build Author

Gary Caruso

Views

24927

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Sword66

Views

14015

Build Author

Sword66

Views

14015

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Julius

Views

25503

Build Author

Julius

Views

25503

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

2752

Build Author

Sprags

Views

2752

C-Beam Kyo Sphinx 10060

More stuff here.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Build Author

TurfnSurf

Views

6226

Build Author

TurfnSurf

Views

6226

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

Hussein Dermay

Views

6531

Build Author

Hussein Dermay

Views

6531

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.