Build List

-

Active Filters:

u

Build Author

Leon Style

Views

4553

Build Author

Leon Style

Views

4553

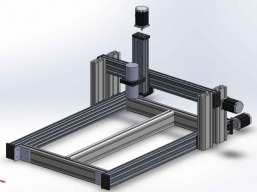

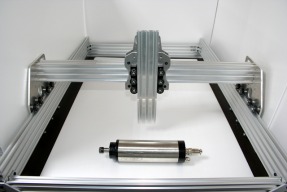

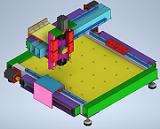

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

Build Author

Pol Feliu

Views

9093

Build Author

Pol Feliu

Views

9093

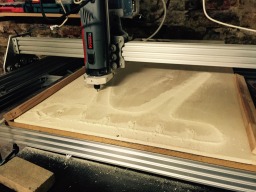

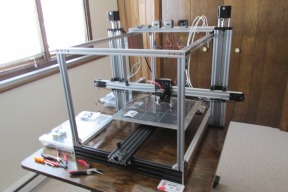

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

Zootalaws

Views

6328

Build Author

Zootalaws

Views

6328

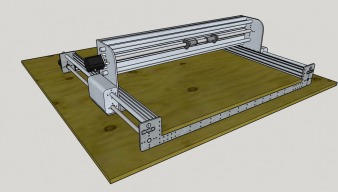

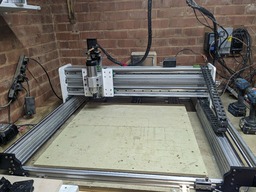

OXENlarged

This is a 1500 x 1500 Ox build

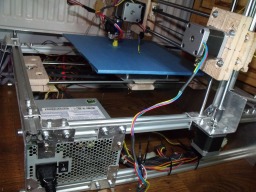

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

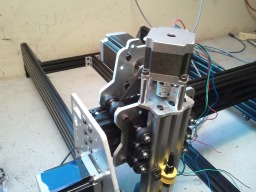

no xp cnc

This is my first cnc build, never used one before and don't know too much besides what i've read a little bit about them online. It's probably going to be about 31" y axis with hopefully around 4ft x axis, z height is still to be determined.

Leveling Gantry

Large leveling platform to hold a 3hp router

Our OX CNC Router Project

Our version of the OX, a Cartesian CNC Router Build. 1,500 mm Y-Axis, 1,000 mm X-Axis, 300 mm Z-Axis - Lots of Fun!

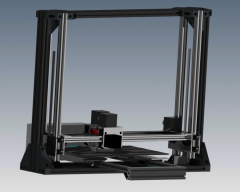

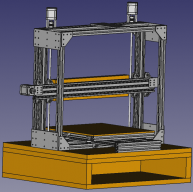

Parthenon

Custom build, after building the prusa i3 and upgrading to i3v, I wanted to build something more sturdy that can print fast and more accurate. Model is built in Fusion 360

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

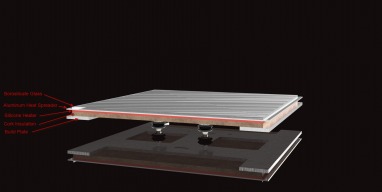

12.5" x 12" Assembled Heated Build Plate

Custom build plate for 300mm x 300mm (12"x12"). The hole pattern is for the 20x60 V Slot

Build Author

inhan

Views

12448

Build Author

inhan

Views

12448

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

KerryH's OX

My adventure in CNC routing.

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Build Author

Anglesachse

Views

8879

Build Author

Anglesachse

Views

8879

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

Build Author

MikieLikesIt

Views

8121

Build Author

MikieLikesIt

Views

8121

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Just Starting

My attempt at planning out my own CNC router

CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

My build is to allow me to cut foam wings using CNC Hot Wire Cutter.

OX

My build of the OX kit from SMW3D.com

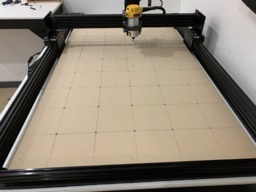

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

Build Author

Fabio Bertuzz

Views

4095

Build Author

Fabio Bertuzz

Views

4095

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

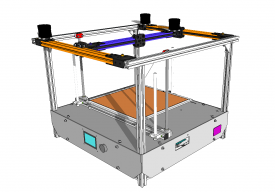

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

zann68

Views

8693

Build Author

zann68

Views

8693

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

5989

Build Author

Gary Bonard

Views

5989

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

mirage335

Views

7216

Build Author

mirage335

Views

7216

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Build Author

Julius

Views

8022

Build Author

Julius

Views

8022

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

Build Author

Cbrown330

Views

5225

Build Author

Cbrown330

Views

5225

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

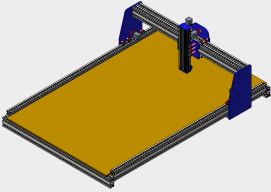

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

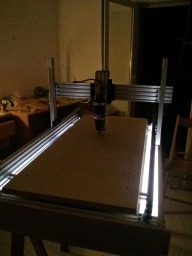

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Builder+Bob

Views

3627

Build Author

Builder+Bob

Views

3627

Portable C-Beam

C-Beam Plate maker for My OX!

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

boubouexpress

Views

11226

Build Author

boubouexpress

Views

11226

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

Infinite Z Delta Printer

Currently completely imaginary

Build Author

Joe Garritano

Views

11323

Build Author

Joe Garritano

Views

11323

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

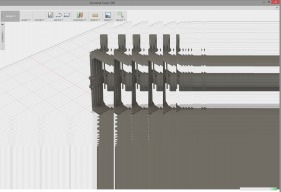

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Build Author

Ken376

Views

3586

Build Author

Ken376

Views

3586

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

Linkreincarnate

Views

2983

Build Author

Linkreincarnate

Views

2983

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

Build Author

Tom Dirriwachter

Views

7172

Build Author

Tom Dirriwachter

Views

7172

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

A work in progress

One of my first projects might be cutting proper plates.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

THE LINK

Views

4963

Build Author

THE LINK

Views

4963

2020 First build.

Probably cheapest DIY build youl see.

Build Author

JerryD

Views

5184

Build Author

JerryD

Views

5184

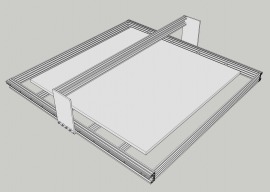

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

h3rb

Views

3549

Build Author

h3rb

Views

3549

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5433

Build Author

h3rb

Views

5433

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

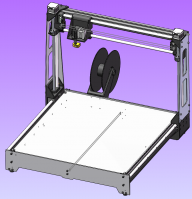

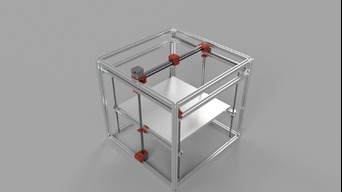

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

Mark Carew

Views

17736

Build Author

Mark Carew

Views

17736

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Mark Carew

Views

12821

Build Author

Mark Carew

Views

12821

C-Beam® Double Wide Gantry Actuator

This easy to build actuator is configured to have not only strength, but accuracy! This low profile option offers endless possibilities, and we cant wait to see how this actuator is implemented in your build ideas!

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

joetemus

Views

6513

Build Author

joetemus

Views

6513

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Taller couch legs

A simple but elegent couch legs

Build Author

Darren Dickson

Views

4134

Build Author

Darren Dickson

Views

4134

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

jeff johnson

Views

5575

Build Author

jeff johnson

Views

5575

workbee 1510

Getting more height out of the !510

Build Author

Tristen Poliseno

Views

3875

Build Author

Tristen Poliseno

Views

3875

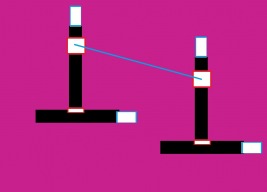

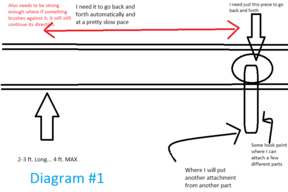

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

Build Author

Leboeuf

Views

4754

Build Author

Leboeuf

Views

4754

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Yosmany325

Views

2249

Build Author

Yosmany325

Views

2249

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Build Author

Jose Alezandre

Views

2061

Build Author

Jose Alezandre

Views

2061

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

Build Author

theracermark

Views

3832

Build Author

theracermark

Views

3832

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

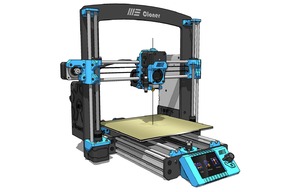

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

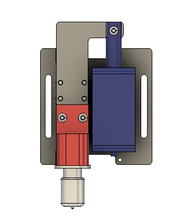

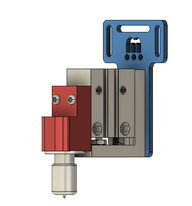

CNC Cutter Knife

CNC knife cutter with loline blades

Pneumatic cnc cutter with festo drive

CNC Glass cutter

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

Build Author

Alexander_Bulgaria

Views

1171

Build Author

Alexander_Bulgaria

Views

1171

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

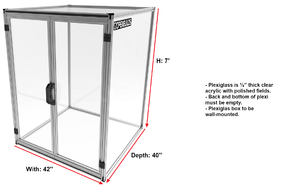

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors