Build List

-

Active Filters:

c

Build Author

Julius

Views

8027

Build Author

Julius

Views

8027

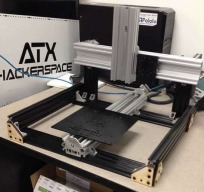

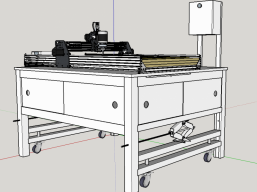

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

My Second CNC

In short...this was a fun project.

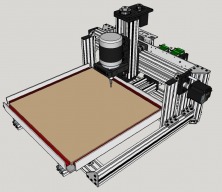

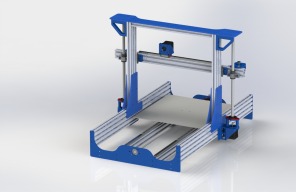

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

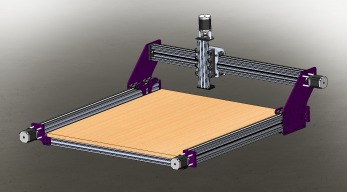

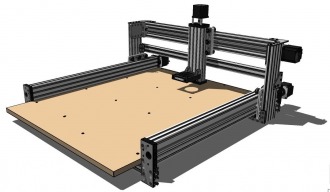

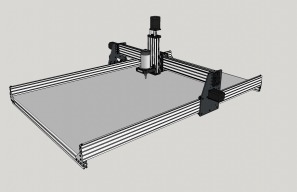

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

bertha

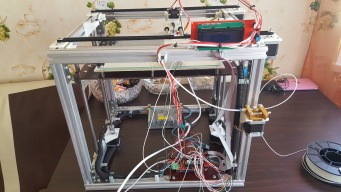

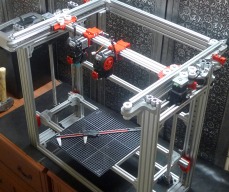

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

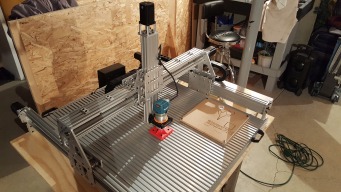

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

Colin Russon

Views

9156

Build Author

Colin Russon

Views

9156

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

evil2002usna

Views

11363

Build Author

evil2002usna

Views

11363

Evil Ox

Cheap Ballscrew Ox CNC Router.

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Builder+Bob

Views

3629

Build Author

Builder+Bob

Views

3629

Portable C-Beam

C-Beam Plate maker for My OX!

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

Build Author

Sonny Lowe

Views

5903

Build Author

Sonny Lowe

Views

5903

MakerSL MSL-7 Laser Cut Tape Dispenser

An easy simple Tape Dispenser, spawned out of necessity, and shared for the fun of it...

Build Author

Paruk

Views

22308

Build Author

Paruk

Views

22308

Buffal-O-Tron

A 3D Scanning Station

Build Author

Charles Roseberry

Views

4883

Build Author

Charles Roseberry

Views

4883

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

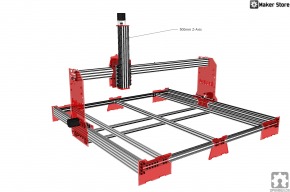

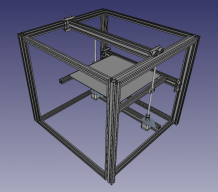

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Build Author

cbordeleau

Views

5943

Build Author

cbordeleau

Views

5943

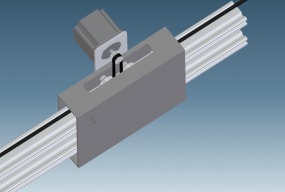

Slider Levelling Platform

3d printed V-Slot Gantry Plate leveler.

Build Author

Rob Taylor

Views

19287

Build Author

Rob Taylor

Views

19287

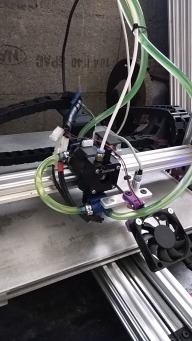

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

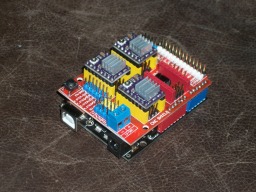

Gargoile reproduction C-Beam™ Machine - Plate Maker

A stock C-Beam with a CNC shield with DRV8825's

Large OX

A larger version of the OX.

Build Author

cbordeleau

Views

12931

Build Author

cbordeleau

Views

12931

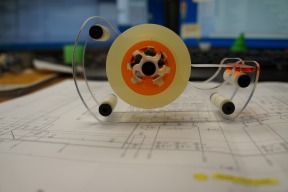

OpenBuilds C-Beam Double Slider

This slider uses an 500mm OpenBuilds C-beam and the design is such that the effective length of the slider is slightly less then twice the length of the C-Beam. It can be used both motorized or not.

My First CNC Machine

This will be a step by step record charting my successes and failures in my voyage of discovery while building a CNC router. Please excuse my English-English which may lose something in translation to American-English. I would be grateful for any advice during the build

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

Matt Nelson

Views

12025

Build Author

Matt Nelson

Views

12025

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

Anthony Bolgar

Views

11753

Build Author

Anthony Bolgar

Views

11753

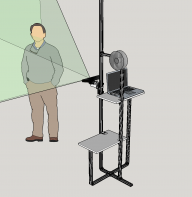

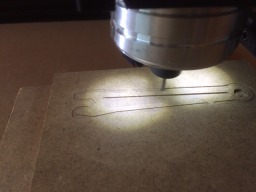

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

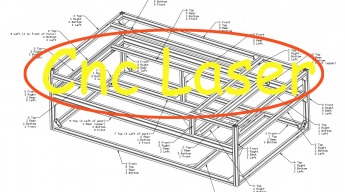

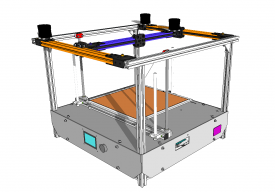

Laser cutter

In the expo projects during the second year of engineering students. the project group who made this rapport made a laser cutter for the students of Fontys Hogeschool Engineering to use this machine for creating parts for their projects. The goal of Project Laser Cutter is to build a laser cutter, which is safe and can be used within the school. Also it has to be able to cut through 10 millimetres thick acrylic material or 10 millimetres thick plywood. This project will follow the V-model. This

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

UltiBots

Views

10387

Build Author

UltiBots

Views

10387

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

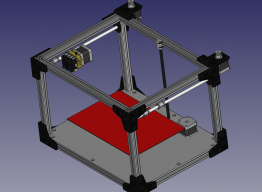

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

CNC

This is my CNC build. My goal is to have fun and learn some new things.

Build Author

eddyg

Views

4814

Build Author

eddyg

Views

4814

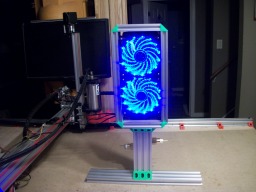

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

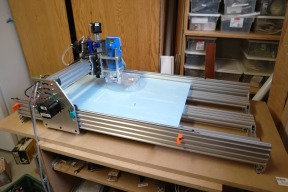

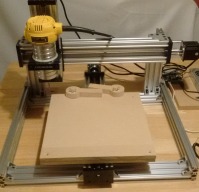

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

Build Author

Metalguru

Views

14272

Build Author

Metalguru

Views

14272

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Rwetzler

Views

9110

Build Author

Rwetzler

Views

9110

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

griso

Views

9030

Build Author

griso

Views

9030

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

boubouexpress

Views

11232

Build Author

boubouexpress

Views

11232

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

CO2 laser cutter

A build which is based on a metal frame and aluminium plate which I salvaged from a skip. The frame is sized to hold 19" rack units so I'll build my control box into a 3U rack unit (also salvaged). The area available for the build is 700x1200mm. I'll sling a 60W CO2 tube under the base, the beam path will be initially upward into the enclosure.

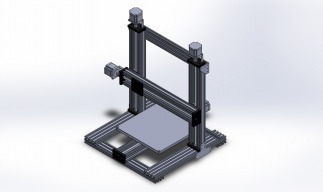

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

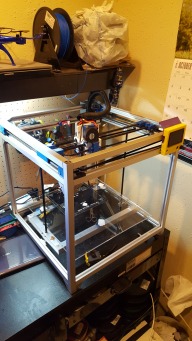

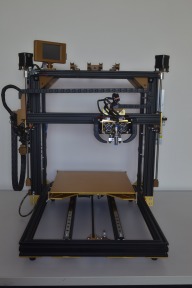

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

Build Author

William Niedermeyer

Views

18798

Build Author

William Niedermeyer

Views

18798

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

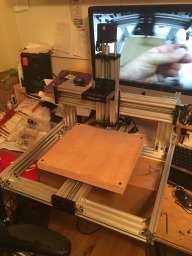

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Jose A. Molina

Views

6794

Build Author

Jose A. Molina

Views

6794

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Simon Rafferty

Views

7401

Build Author

Simon Rafferty

Views

7401

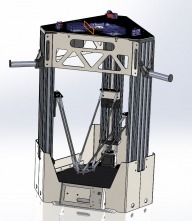

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

Schematix OX metal build

OX metal build from an noob

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Build Author

Krishnakumar

Views

8325

Build Author

Krishnakumar

Views

8325

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

Jose A. Molina

Views

6758

Build Author

Jose A. Molina

Views

6758

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

AK-Creation

Views

14617

Build Author

AK-Creation

Views

14617

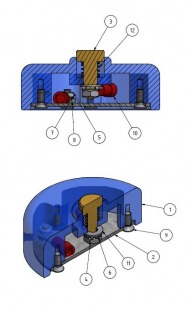

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Spindle cooling setup

Cooling system for water cooled spindle.

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

crystaldragon141

Views

6401

Build Author

crystaldragon141

Views

6401

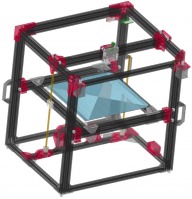

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

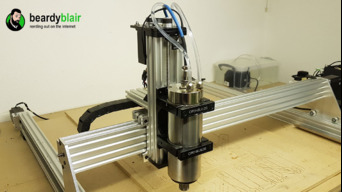

Build Author

beardyblair

Views

25027

Build Author

beardyblair

Views

25027

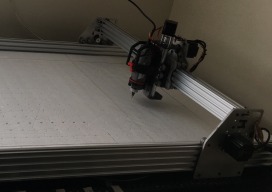

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

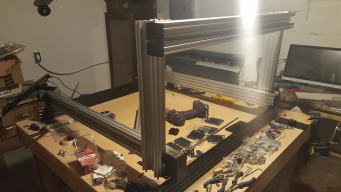

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Laser engraver

Just a little light duty laser engraver.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Build Author

Edgar Robles

Views

3955

Build Author

Edgar Robles

Views

3955

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Power Playground

Views

4668

Build Author

Power Playground

Views

4668

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

C-Machine

MY experience as a first time introduction to the CNC world!

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Build Author

sgspenceley

Views

8456

Build Author

sgspenceley

Views

8456

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Linear Rail for Dobot Magician

This is a simpel build of a Linear rail for the Dobot Magician.

Build Author

Ken376

Views

3589

Build Author

Ken376

Views

3589

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

JP Warnke

Views

12572

Build Author

JP Warnke

Views

12572

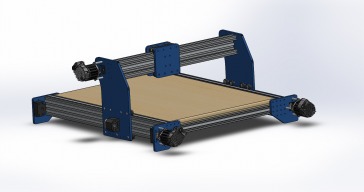

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

dodgenet

Views

6453

Build Author

dodgenet

Views

6453

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

mikev

Views

8391

Build Author

mikev

Views

8391

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Anthony Bolgar

Views

5596

Build Author

Anthony Bolgar

Views

5596

Air assist/fume collector for Diode Laser Engraver

This is a work in progress