Build List

-

Active Filters:

all

Build Author

Carl Feniak

Views

285574

Build Author

Carl Feniak

Views

285574

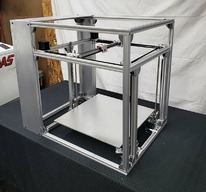

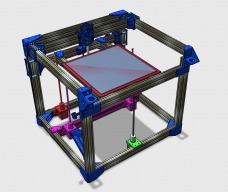

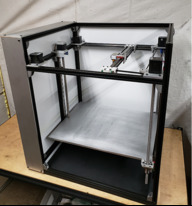

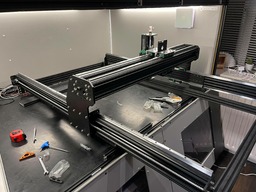

C-Bot

A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy.

Build Author

sgspenceley

Views

209259

Build Author

sgspenceley

Views

209259

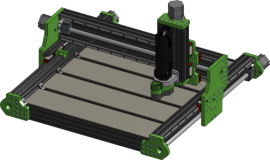

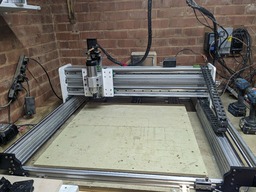

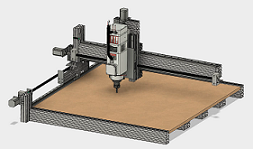

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

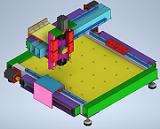

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

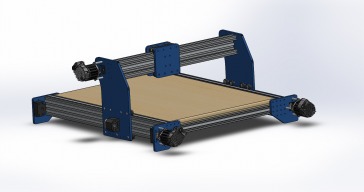

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Build Author

alex_b

Views

19416

Build Author

alex_b

Views

19416

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Build Author

Julius

Views

25746

Build Author

Julius

Views

25746

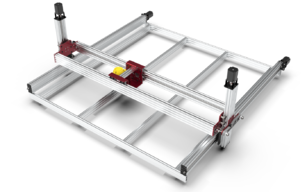

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

Michael.M

Views

9860

Build Author

Michael.M

Views

9860

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

BeTrue3D

Views

22749

Build Author

BeTrue3D

Views

22749

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

Sonny Lowe

Views

7140

Build Author

Sonny Lowe

Views

7140

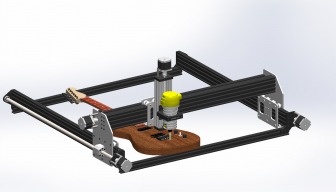

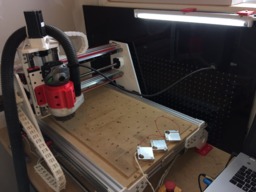

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Build Author

Alexander Leiser

Views

22894

Build Author

Alexander Leiser

Views

22894

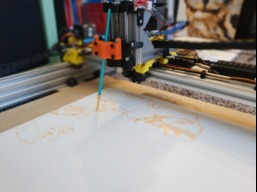

Paintbot painting cnc

Custom painting machine in designed and wrote the software for. Paintings are with acrylic color on canvas

Build Author

Scott Martinez

Views

12424

Build Author

Scott Martinez

Views

12424

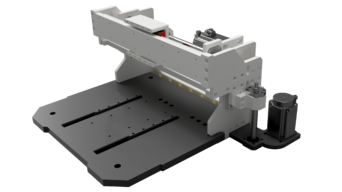

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

HuguesP

Views

9410

Build Author

HuguesP

Views

9410

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

MiniMill

Building a small mill to match my 7x12 lathe.

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

Corey Corbin

Views

8063

Build Author

Corey Corbin

Views

8063

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

Andrew Helsel

Views

12393

Build Author

Andrew Helsel

Views

12393

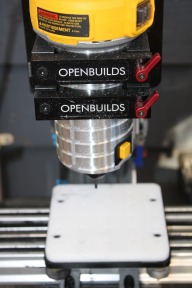

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

EvanH

Views

5336

Build Author

EvanH

Views

5336

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Build Author

brw_racing

Views

16507

Build Author

brw_racing

Views

16507

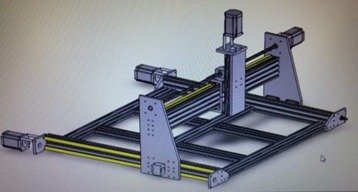

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

Build Author

Vunnie

Views

6939

Build Author

Vunnie

Views

6939

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

Rob Taylor

Views

19346

Build Author

Rob Taylor

Views

19346

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Build Author

John J Talavera

Views

18864

Build Author

John J Talavera

Views

18864

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Build Author

Gerald Klein

Views

17686

Build Author

Gerald Klein

Views

17686

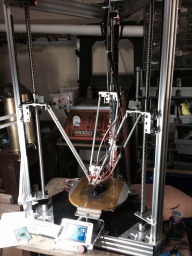

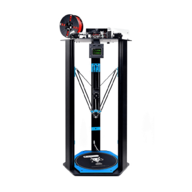

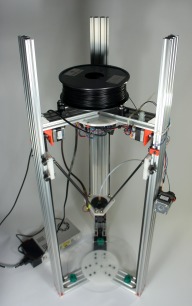

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

Build Author

James Evanko

Views

7601

Build Author

James Evanko

Views

7601

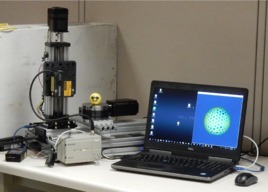

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

patnap71

Views

7055

Build Author

patnap71

Views

7055

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

Troy Proffitt

Views

29444

Build Author

Troy Proffitt

Views

29444

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Alexander_Bulgaria

Views

1892

Build Author

Alexander_Bulgaria

Views

1892

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

joetemus

Views

7094

Build Author

joetemus

Views

7094

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

David Florian

Views

12120

Build Author

David Florian

Views

12120

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

mathom713

Views

9785

Build Author

mathom713

Views

9785

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

Build Author

shanehooper

Views

16331

Build Author

shanehooper

Views

16331

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Yosmany325

Views

2525

Build Author

Yosmany325

Views

2525

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Build Author

Colin Russon

Views

4038

Build Author

Colin Russon

Views

4038

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

CNCGear

Views

10983

Build Author

CNCGear

Views

10983

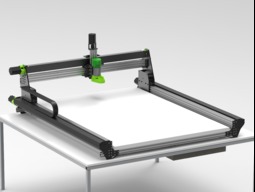

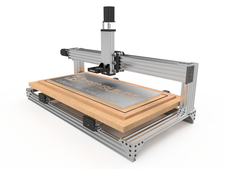

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Build Author

Sigifredo Cruz Rojas

Views

4201

Build Author

Sigifredo Cruz Rojas

Views

4201

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

zero z mongrel

long overdue overhaul of 1000 x 1000 machine

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Build Author

John J Talavera

Views

12325

Build Author

John J Talavera

Views

12325

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

KBill

Views

13699

Build Author

KBill

Views

13699

MIY OLY Delta Printer

Mag arm deltabot with laser cut carriages and connectors.

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Build Author

Gary Bonard

Views

6329

Build Author

Gary Bonard

Views

6329

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Julius

Views

8316

Build Author

Julius

Views

8316

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

Build Author

Colin Russon

Views

9605

Build Author

Colin Russon

Views

9605

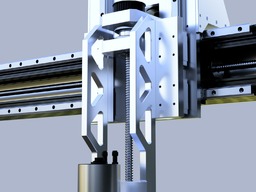

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

evil2002usna

Views

11695

Build Author

evil2002usna

Views

11695

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

dodgenet

Views

6745

Build Author

dodgenet

Views

6745

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Chetan PM

Views

3946

Build Author

Chetan PM

Views

3946

Composer

Gantry style rigid build

Build Author

evgeny156

Views

7454

Build Author

evgeny156

Views

7454

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

thinman

Views

9004

Build Author

thinman

Views

9004

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

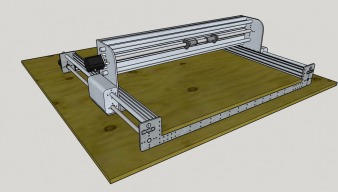

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

TurfnSurf

Views

6334

Build Author

TurfnSurf

Views

6334

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

TurfnSurf

Views

7308

Build Author

TurfnSurf

Views

7308

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Bucky Wootmaster

Views

3115

Build Author

Bucky Wootmaster

Views

3115

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Delta without vertices

As this is a build in progress, I will update it as I progress.

Build Author

Andreas Bockert

Views

12220

Build Author

Andreas Bockert

Views

12220

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

SCYBUCK

Views

5240

Build Author

SCYBUCK

Views

5240

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

C-CNC

Views

16761

Build Author

C-CNC

Views

16761

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

deltajegga

Views

10107

Build Author

deltajegga

Views

10107

THE delta

probably as big as you'd want it...

Build Author

James Evanko

Views

5071

Build Author

James Evanko

Views

5071

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.