Build List

-

Active Filters:

nc

Build Author

evil2002usna

Views

11558

Build Author

evil2002usna

Views

11558

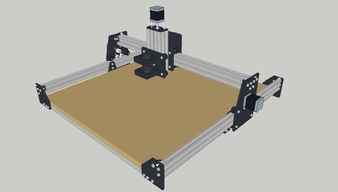

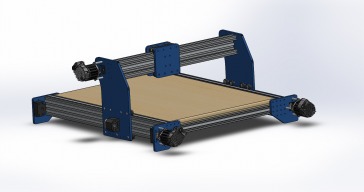

Evil Ox

Cheap Ballscrew Ox CNC Router.

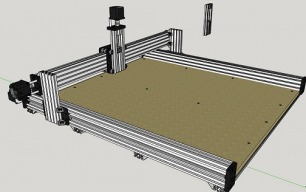

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

Build Author

Yanou Fishel

Views

11367

Build Author

Yanou Fishel

Views

11367

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

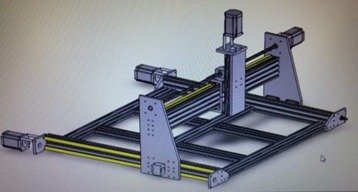

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Ooznest OX CNC Build

Ooznest OX CNC build

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

Build Author

Mike Campbell

Views

11127

Build Author

Mike Campbell

Views

11127

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Bear

Views

11047

Build Author

Bear

Views

11047

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

Build Author

Rob Taylor

Views

10932

Build Author

Rob Taylor

Views

10932

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

Steven Sampson

Views

10922

Build Author

Steven Sampson

Views

10922

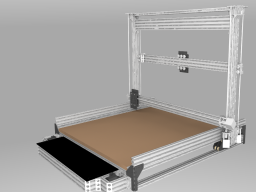

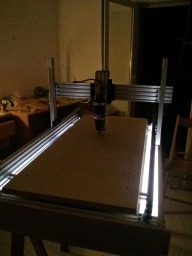

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

RoStockFAZZ

My large printer design. 400mm build plate, ~1000mm build height. Most of structure is 8020 but the sliders are V-Rail

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

Build Author

dcarlisle

Views

10734

Build Author

dcarlisle

Views

10734

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

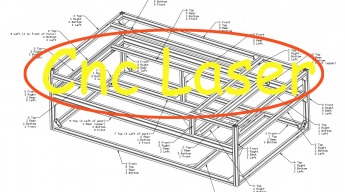

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

Build Author

Darren Ditto

Views

10682

Build Author

Darren Ditto

Views

10682

V 1.4 - Bright Box Cartesian Printer - *BUILD PROGRESS PICTURES

Cartesian Printer, 200mm x 200mm x 380mm build area, enclosed, belt and pinion movement, heated bed, Raspberry Pi, Pi Cam, OctoPrint

Build Author

CNCGear

Views

10617

Build Author

CNCGear

Views

10617

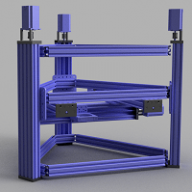

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Apple Crate CNC

Low cost, apple crate framed CNC.

Build Author

Kyo

Views

10594

Build Author

Kyo

Views

10594

Fina

This is Fina; My Lautr3k inspired build.

Open Rail Build

This will be a chronicle. It's my first CNC build so, I will be making many changes as I learn from my mistakes. I will pass on any tips or tricks i learn along the way. This build is an OX Hybrid. I decided to use the open rail with the V wheels and not to go with the V Slot. (I'll let you know how it works out.)

Build Author

UltiBots

Views

10560

Build Author

UltiBots

Views

10560

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

Lasersc

Views

10461

Build Author

Lasersc

Views

10461

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

StrictlyScale

Views

10434

Build Author

StrictlyScale

Views

10434

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Build Author

Pendragon

Views

10309

Build Author

Pendragon

Views

10309

bOX

A bigger OX. As this build is nothing new I will detail my build process, I am not an experienced builder, this will maybe help someone else. The size of the bOX will be 100cmx75cm. I will use aluminium plates, a tinyG, and most probably only open source / free software.

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

Build Author

Larry_AK

Views

10263

Build Author

Larry_AK

Views

10263

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

Build Author

Superslinky

Views

10238

Build Author

Superslinky

Views

10238

K40 Laser Build (Major Changes)

Major K40 Laser Mod

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

V-Slot Workbench

A Workbench idea built from V-slot and openbuilds parts.

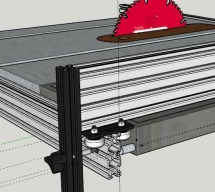

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Philippe Bergeron

Views

10101

Build Author

Philippe Bergeron

Views

10101

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

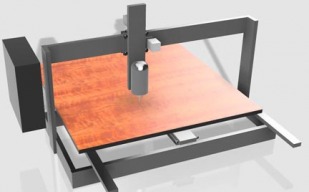

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Build Author

Kyo

Views

10072

Build Author

Kyo

Views

10072

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

Build Author

Christian James

Views

9934

Build Author

Christian James

Views

9934

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

Ahmed Ibrahim

Views

9887

Build Author

Ahmed Ibrahim

Views

9887

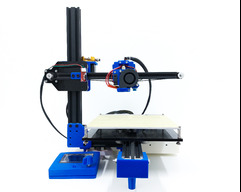

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

Build Author

Frank Gore

Views

9846

Build Author

Frank Gore

Views

9846

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

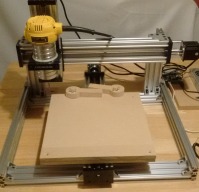

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Build Author

Keith Davis

Views

9828

Build Author

Keith Davis

Views

9828

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

Build Author

Michael.M

Views

9661

Build Author

Michael.M

Views

9661

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Asaku

Views

9649

Build Author

Asaku

Views

9649

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Controll Board for CNC Projects

The Echinus Team change the Firmware from "Teacup" to "Marlin". I use this board in my 3D Printer and it works very good! So I write a short report.

OX

My build of the OX kit from SMW3D.com

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

Nicademus

Views

9549

Build Author

Nicademus

Views

9549

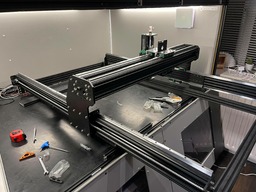

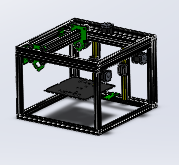

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Maxime Favre

Views

9530

Build Author

Maxime Favre

Views

9530

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Christer Langley

Views

9448

Build Author

Christer Langley

Views

9448

CNC-Solutions Build

My first Build with V-slot

Build Author

Colin Russon

Views

9418

Build Author

Colin Russon

Views

9418

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Jesse Jenkins

Views

9409

Build Author

Jesse Jenkins

Views

9409

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Quentin Karmark

Views

9408

Build Author

Quentin Karmark

Views

9408

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

Rwetzler

Views

9365

Build Author

Rwetzler

Views

9365

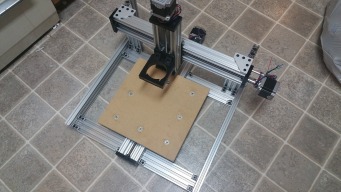

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

Gooshpoo

Views

9322

Build Author

Gooshpoo

Views

9322

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

zann68

Views

9288

Build Author

zann68

Views

9288

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Huub65

Views

9282

Build Author

Huub65

Views

9282

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

Pol Feliu

Views

9262

Build Author

Pol Feliu

Views

9262

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

Bridge Port

Views

9221

Build Author

Bridge Port

Views

9221

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Build Author

Greg Lampman

Views

9218

Build Author

Greg Lampman

Views

9218

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Justin Butler

Views

9200

Build Author

Justin Butler

Views

9200

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Build Author

motopreserve

Views

9082

Build Author

motopreserve

Views

9082

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

Build Author

Tucstrlly

Views

9069

Build Author

Tucstrlly

Views

9069

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Anglesachse

Views

9048

Build Author

Anglesachse

Views

9048

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

Build Author

Richard Bugland

Views

8986

Build Author

Richard Bugland

Views

8986

Heavy Inexpensive CNC

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

Build Author

Mark Carew

Views

8966

Build Author

Mark Carew

Views

8966

OpenBuilds PowerCase

A simple to assemble, super clean and safe PSU case solution that fits into the OpenBuilds wire management ecosystem

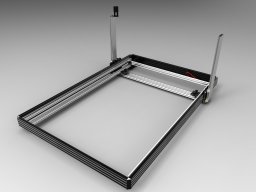

Linear Rail derivative with ball screw

basic start to design of cnc machine

CNC CARDBOARD BOX CUTTER

Just an easy build .... uncomplicated.... simple tools .... but hoping for a good result!

Build Author

Karan Singh Sisodia

Views

8894

Build Author

Karan Singh Sisodia

Views

8894

CNC Laser

CoreXY based CNC Laser machine.

Build Author

evildean

Views

8886

Build Author

evildean

Views

8886

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

Build Author

DiggerJ

Views

8770

Build Author

DiggerJ

Views

8770

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Build Author

Krishnakumar

Views

8725

Build Author

Krishnakumar

Views

8725

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

Build Author

CWidt

Views

8708

Build Author

CWidt

Views

8708

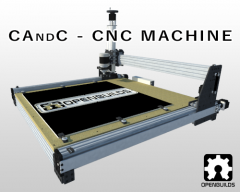

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Build Author

Colin Russon

Views

8696

Build Author

Colin Russon

Views

8696

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Our OX CNC Router Project

Our version of the OX, a Cartesian CNC Router Build. 1,500 mm Y-Axis, 1,000 mm X-Axis, 300 mm Z-Axis - Lots of Fun!

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Build Author

mikev

Views

8576

Build Author

mikev

Views

8576

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Joe F

Views

8481

Build Author

Joe F

Views

8481

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

John J Talavera

Views

8470

Build Author

John J Talavera

Views

8470

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Schematix OX metal build

OX metal build from an noob

Build Author

Mohsen Abbasi

Views

8344

Build Author

Mohsen Abbasi

Views

8344

Portable Foam Cutter

A portable foam cutter to make your forms everyware using a LiPo Battery.

Build Author

MikieLikesIt

Views

8258

Build Author

MikieLikesIt

Views

8258

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

richthorn

Views

8257

Build Author

richthorn

Views

8257

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

DoubleX

This is a Dual X-axis platform.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.