Build List

-

Active Filters:

be

Build Author

KronBjorn

Views

4405

Build Author

KronBjorn

Views

4405

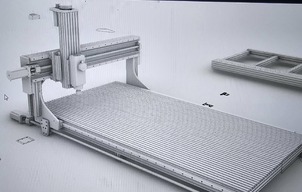

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

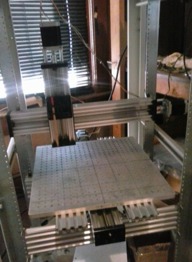

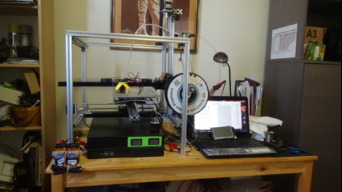

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

Darren Dickson

Views

4322

Build Author

Darren Dickson

Views

4322

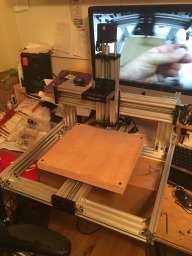

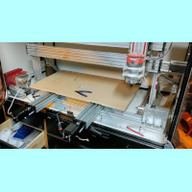

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

BCulbertson

Views

4311

Build Author

BCulbertson

Views

4311

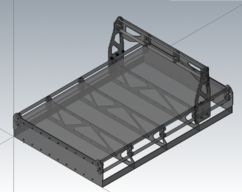

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

Build Author

Doug Rowley

Views

4272

Build Author

Doug Rowley

Views

4272

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

TimVukman

Views

4250

Build Author

TimVukman

Views

4250

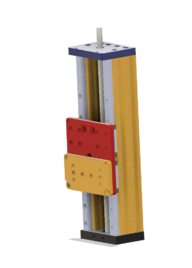

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

RV6APilot

Views

4161

Build Author

RV6APilot

Views

4161

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.

Build Author

crnrstndes

Views

4107

Build Author

crnrstndes

Views

4107

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

Steve Hall

Views

4105

Build Author

Steve Hall

Views

4105

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

James Evanko

Views

4019

Build Author

James Evanko

Views

4019

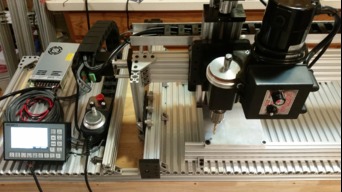

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

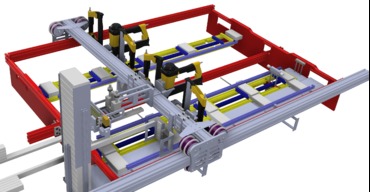

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

Jones

Views

3906

Build Author

Jones

Views

3906

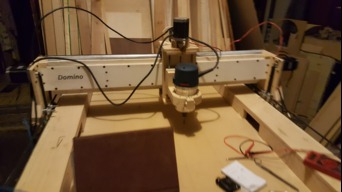

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Build Author

Cam Garrett

Views

3896

Build Author

Cam Garrett

Views

3896

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Build Author

Rich Bowen

Views

3789

Build Author

Rich Bowen

Views

3789

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

Thair.nl

Views

3729

Build Author

Thair.nl

Views

3729

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

Builder+Bob

Views

3701

Build Author

Builder+Bob

Views

3701

Portable C-Beam

C-Beam Plate maker for My OX!

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Build Author

Ken376

Views

3683

Build Author

Ken376

Views

3683

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

bpatterson42

Views

3494

Build Author

bpatterson42

Views

3494

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

My Workbee build

Workbee, 1000mmX750mm , from China

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Build Author

Stan Howe

Views

3250

Build Author

Stan Howe

Views

3250

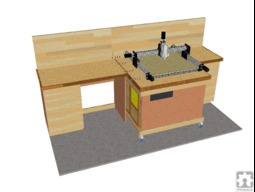

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

hbtousa

Views

3195

Build Author

hbtousa

Views

3195

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

Anthony Castelluci

Views

3181

Build Author

Anthony Castelluci

Views

3181

Simple Camera Lofted Camera Slider

Build a manual camera slider.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Axnfell

Views

3008

Build Author

Axnfell

Views

3008

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Workbee with less irritations

My workbee build with some add ons

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Something a Tad different

Future CNC router kit design

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

Terone Burgenheim

Views

2774

Build Author

Terone Burgenheim

Views

2774

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

OoozNest WorkBee

A Journey on the WorkBee Build...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip

What impact will unstable voltage have on the laser cutting machine?

How can we protect our expensive lasers and electronic components?"