Build List

-

Active Filters:

cnc

Build Author

Larry_AK

Views

10302

Build Author

Larry_AK

Views

10302

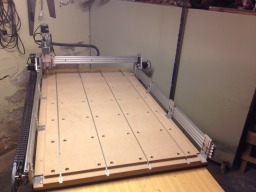

MUSK-OX

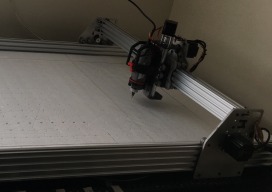

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

MyCNC(1000mm x 1500mm)

My CNC project

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

C-Machine

MY experience as a first time introduction to the CNC world!

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

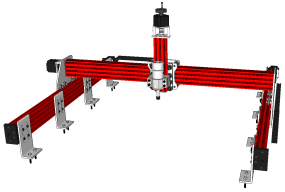

cnc plasma table

ive got most of the wire harness made up too im using Chinese electronics for now I will upgrade later when this thing makes me some cash lol im using a ibm think center to case to hold my electronics ive got a 25' parallel cable to put some distance between the table and the computer

Build Author

Edgar Robles

Views

4124

Build Author

Edgar Robles

Views

4124

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Maxime Favre

Views

9564

Build Author

Maxime Favre

Views

9564

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

Build Author

Mark Carew

Views

74942

Build Author

Mark Carew

Views

74942

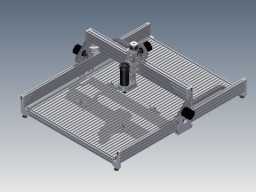

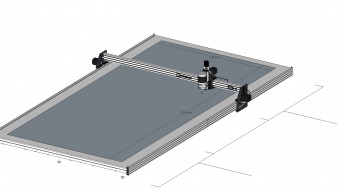

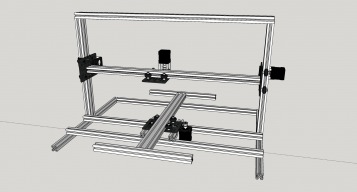

X Y Table OpenRail / V-Slot Build Examples

The X/Y table system is a great starting point for many CNC projects giving you the ability to move an object on the X and Y axis in a simple compact style.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

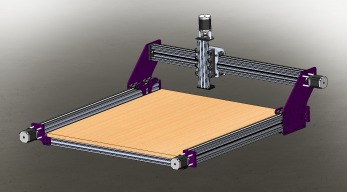

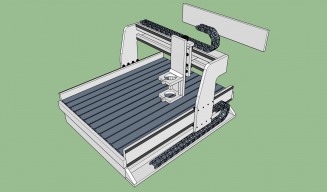

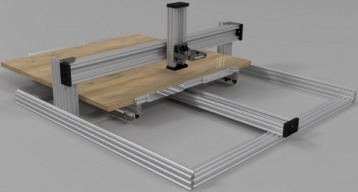

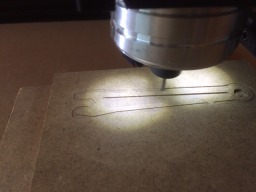

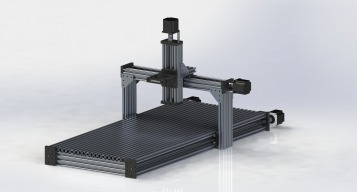

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Build Author

AK-Creation

Views

15023

Build Author

AK-Creation

Views

15023

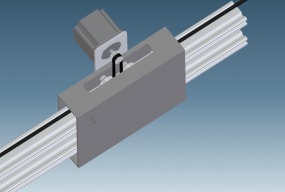

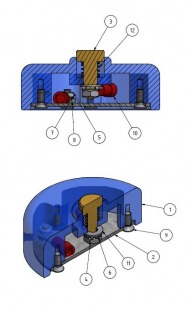

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Schematix OX metal build

OX metal build from an noob

Build Author

sw3Dp

Views

11918

Build Author

sw3Dp

Views

11918

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Build Author

Krishnakumar

Views

8830

Build Author

Krishnakumar

Views

8830

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

k nest

This Build Is Is Inspired By OOZ Nest CNC, But With Some Changes,

Build Author

Bridge Port

Views

9342

Build Author

Bridge Port

Views

9342

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

Build Author

Asaku

Views

9697

Build Author

Asaku

Views

9697

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Build Author

Anglesachse

Views

9082

Build Author

Anglesachse

Views

9082

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

The Buffalo

OX 1500 x 1000 mm

Build Author

Matt Nelson

Views

12373

Build Author

Matt Nelson

Views

12373

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

Peter Oakes

Views

44409

Build Author

Peter Oakes

Views

44409

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

UltiBots

Views

10603

Build Author

UltiBots

Views

10603

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12614

Build Author

AndersFaust

Views

12614

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

Rwetzler

Views

9460

Build Author

Rwetzler

Views

9460

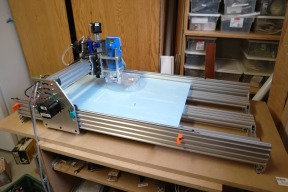

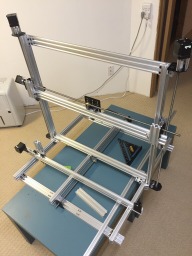

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

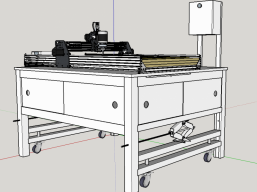

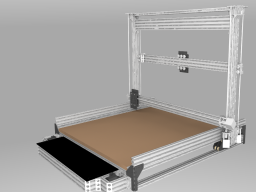

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

Build Author

Julius

Views

8244

Build Author

Julius

Views

8244

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Dave420

Views

6190

Build Author

Dave420

Views

6190

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

Jesse Jenkins

Views

9458

Build Author

Jesse Jenkins

Views

9458

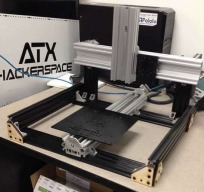

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

CNC

This is my CNC build. My goal is to have fun and learn some new things.

Powder coated multi CNC Z Axis plasma adapter with Prox.

Powder coated multi CNC Z Axis plasma adapter with Proximity sensor. . It can also hold a 80mm Router head/Spindle as seen in my router build.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Build Author

Gerrald

Views

6419

Build Author

Gerrald

Views

6419

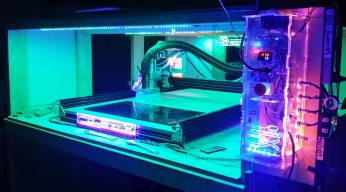

Pong CNC

This build is to show what's possible as well with openBuilds! I use a single ArduinoMega and 5 separate stepper drivers (A4988). The LEDs are all NeoPixels. Collision 'detection' is all done within the code, so the endstops are only sensors I use in this build. I'm a self-employed video-artist and this is my first installation which just needs power and it runs (where I'm quite proud of). Normally my interactive installations take a long setup time, so this installation is a relief :)

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Build Author

rusirius

Views

16977

Build Author

rusirius

Views

16977

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Large OX

A larger version of the OX.

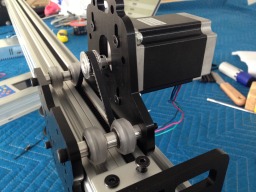

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

Build Author

Charles Roseberry

Views

5096

Build Author

Charles Roseberry

Views

5096

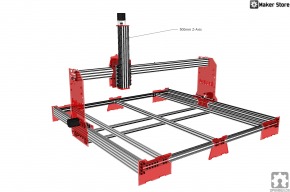

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

My Second CNC

In short...this was a fun project.

Build Author

Robert Hummel

Views

73487

Build Author

Robert Hummel

Views

73487

890KV OX RC spindle

This build is intended as a light alternative to the Dremel rotary tool.

Build Author

John J Talavera

Views

8524

Build Author

John J Talavera

Views

8524

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Build Author

Builder+Bob

Views

3785

Build Author

Builder+Bob

Views

3785

Portable C-Beam

C-Beam Plate maker for My OX!

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

Aluminium OX - Canada

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

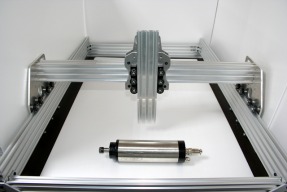

CNC Router (Non OX)

My own Design (not an OX Derivative) using standard Parts.

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

C beam cnc modified

C beam cnc modified

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Build Author

David Arroyo

Views

14746

Build Author

David Arroyo

Views

14746

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

Build Author

zann68

Views

9396

Build Author

zann68

Views

9396

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Apple Crate CNC

Low cost, apple crate framed CNC.

Build Author

Kermareg

Views

17393

Build Author

Kermareg

Views

17393

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

alex_b

Views

17337

Build Author

alex_b

Views

17337

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Build Author

evildean

Views

8947

Build Author

evildean

Views

8947

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

Gary Bonard

Views

6210

Build Author

Gary Bonard

Views

6210

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

OX-Based Self-Contaned HVLP Spray Booth

A CNC HVLP spray booth based on OX.

Build Author

motopreserve

Views

9130

Build Author

motopreserve

Views

9130

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

Build Author

dcarlisle

Views

10797

Build Author

dcarlisle

Views

10797

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

DoubleX

This is a Dual X-axis platform.

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

OX

My build of the OX kit from SMW3D.com

Build Author

Skoobs

Views

4981

Build Author

Skoobs

Views

4981

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

Aluminium Router From Dubai

Another modification on the OX

Build Author

CubeSpawn

Views

16146

Build Author

CubeSpawn

Views

16146

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

Steve hope

Views

19265

Build Author

Steve hope

Views

19265

8x4 CNC build

Routy cnc upgrade.

Build Author

inhan

Views

12636

Build Author

inhan

Views

12636

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

Just Starting

My attempt at planning out my own CNC router

Build Author

Bear

Views

11103

Build Author

Bear

Views

11103

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Build Author

openhardwarecoza

Views

7158

Build Author

openhardwarecoza

Views

7158

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

Build Author

Mark Carew

Views

14854

Build Author

Mark Carew

Views

14854

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

winand

Views

18062

Build Author

winand

Views

18062

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

Build Author

CWidt

Views

8774

Build Author

CWidt

Views

8774

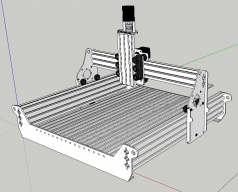

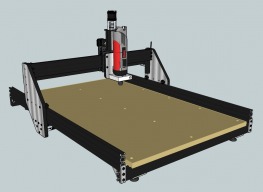

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.