Build List

Build Author

dodgenet

Views

6613

Build Author

dodgenet

Views

6613

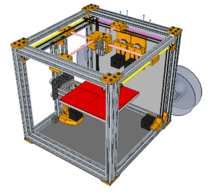

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

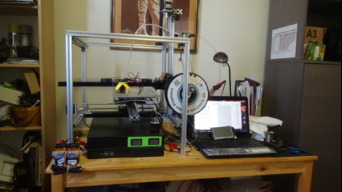

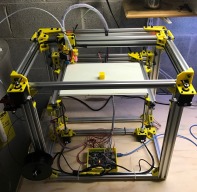

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

Anthony Bolgar

Views

5754

Build Author

Anthony Bolgar

Views

5754

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

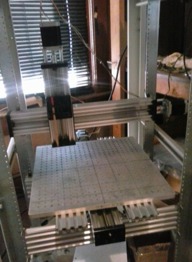

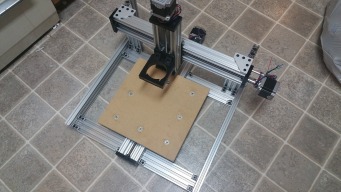

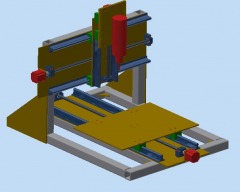

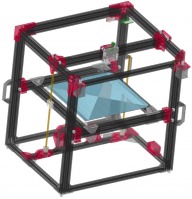

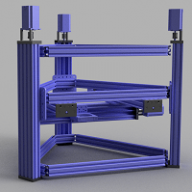

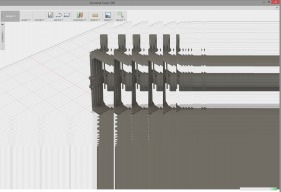

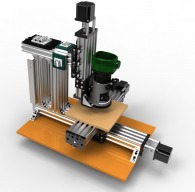

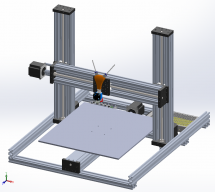

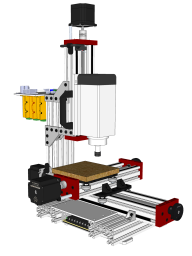

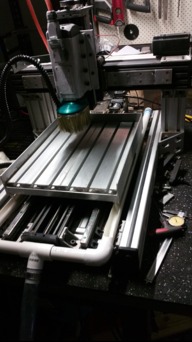

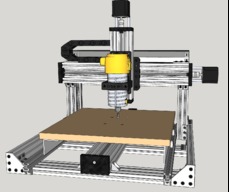

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

TouchPadKing

Views

5111

Build Author

TouchPadKing

Views

5111

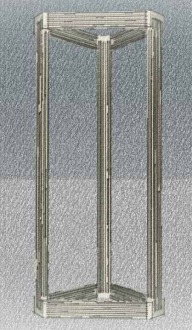

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Build Author

Thair.nl

Views

3822

Build Author

Thair.nl

Views

3822

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

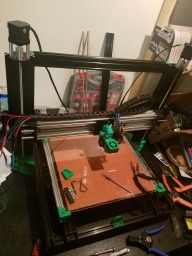

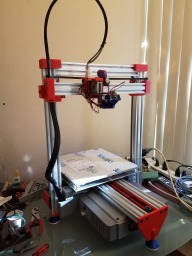

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Build Author

Linkreincarnate

Views

3151

Build Author

Linkreincarnate

Views

3151

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

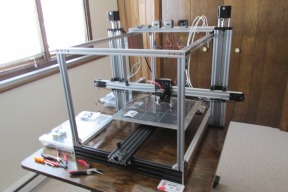

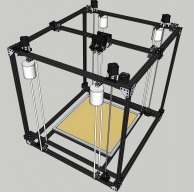

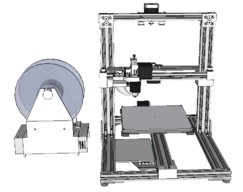

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

Build Author

Kyo

Views

6539

Build Author

Kyo

Views

6539

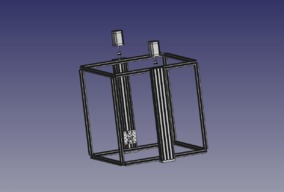

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8636

Build Author

taratata2016

Views

8636

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8579

Build Author

Limine3D

Views

8579

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

COMsulting

Views

10107

Build Author

COMsulting

Views

10107

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Clock repair stand

Open source clock movement stand

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

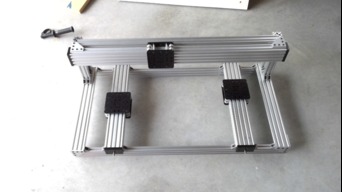

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Greg Lampman

Views

9239

Build Author

Greg Lampman

Views

9239

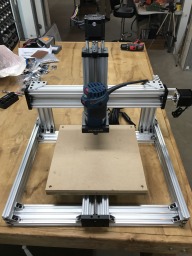

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Dmknerr

Views

5229

Build Author

Dmknerr

Views

5229

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

A work in progress

One of my first projects might be cutting proper plates.

Build Author

McAdam

Views

3751

Build Author

McAdam

Views

3751

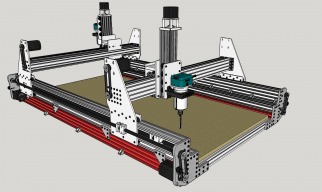

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

Robert Huxford

Views

4003

Build Author

Robert Huxford

Views

4003

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7532

Build Author

Matt Barile

Views

7532

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

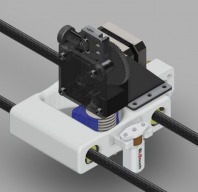

Double trolley X and Z belt training

Total belt drive GT2

Build Author

J-Wahl Dezign

Views

9154

Build Author

J-Wahl Dezign

Views

9154

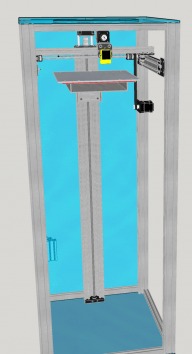

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

Rich Bowen

Views

3853

Build Author

Rich Bowen

Views

3853

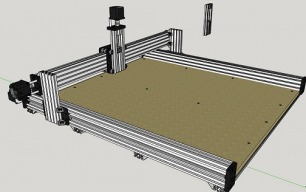

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Robert E. Nee

Views

17516

Build Author

Robert E. Nee

Views

17516

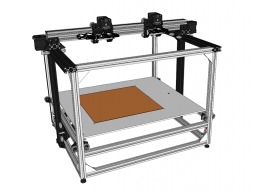

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

DIY LED acrylic lamp

This is a simple lamp using only 2 LEDs & 2 AAA batteries.

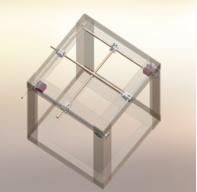

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

nschreiber0813

Views

5498

Build Author

nschreiber0813

Views

5498

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

THE LINK

Views

5093

Build Author

THE LINK

Views

5093

2020 First build.

Probably cheapest DIY build youl see.

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

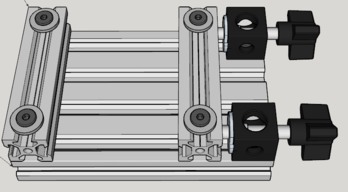

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hisha

Views

5066

Build Author

Hisha

Views

5066

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

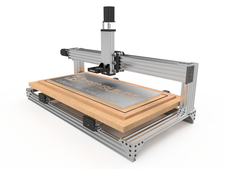

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

evgeny156

Views

7350

Build Author

evgeny156

Views

7350

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Jens Grabner

Views

4149

Build Author

Jens Grabner

Views

4149

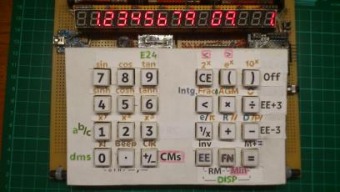

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Fabio Orsi

Views

6950

Build Author

Fabio Orsi

Views

6950

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

megashub

Views

24311

Build Author

megashub

Views

24311

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

JerryD

Views

5352

Build Author

JerryD

Views

5352

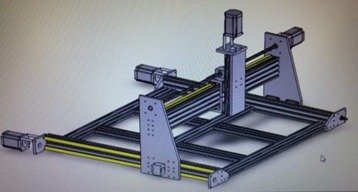

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

V-Slot MAME cabinet

A minimalist MAME "cabinet" made from extrusion.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4100

Build Author

Jason Harding

Views

4100

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

DIY Ultimaker

This design should give the same performance as the high speed Ultimaker since it uses a similar ultra-light X/Y concept which eliminates any movement of both the X and Y motors to achieve X/Y travel.

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

Jeremiah Guinn

Views

5841

Build Author

Jeremiah Guinn

Views

5841

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Brokkr CNC 2.0

1M C-beam xy variant

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Tucstrlly

Views

9097

Build Author

Tucstrlly

Views

9097

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Build Author

TimVukman

Views

4318

Build Author

TimVukman

Views

4318

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

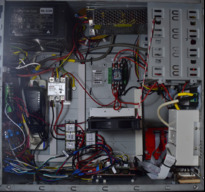

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

patdee

Views

5119

Build Author

patdee

Views

5119

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Ooznest workbee

This is my first build so I will let you know how I get on

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)