Build List

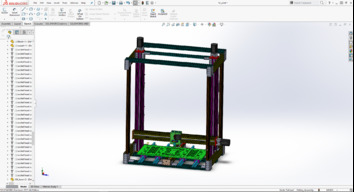

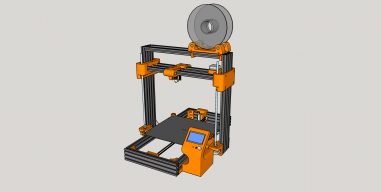

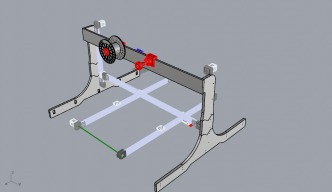

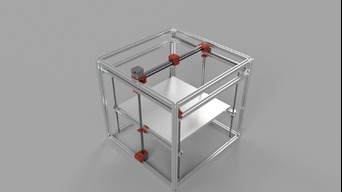

Lead screw printer

High quality e3d parts with a minimalist design

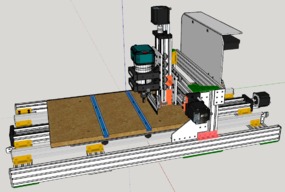

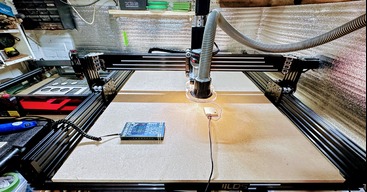

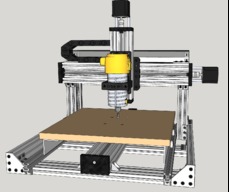

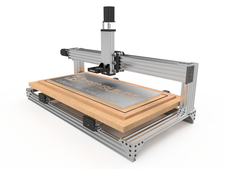

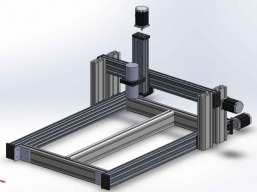

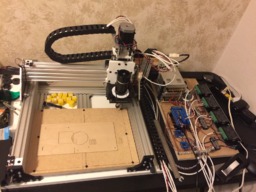

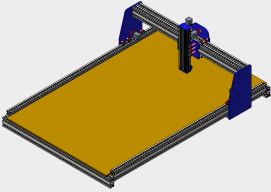

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

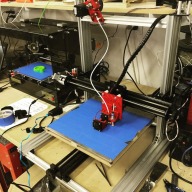

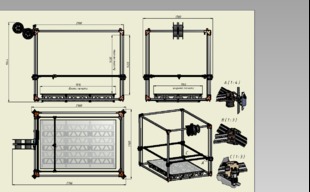

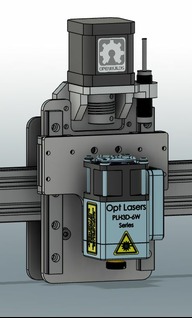

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

Build Author

SCYBUCK

Views

5178

Build Author

SCYBUCK

Views

5178

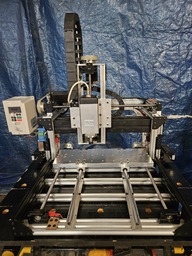

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Corey Corbin

Views

5172

Build Author

Corey Corbin

Views

5172

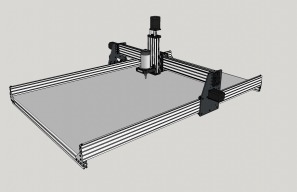

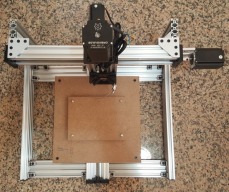

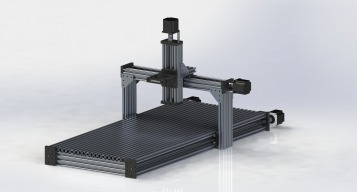

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

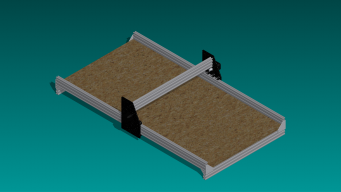

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

TouchPadKing

Views

5148

Build Author

TouchPadKing

Views

5148

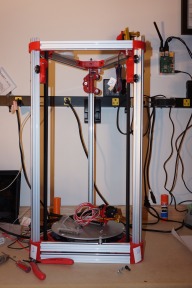

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

THE LINK

Views

5137

Build Author

THE LINK

Views

5137

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Hisha

Views

5132

Build Author

Hisha

Views

5132

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

EvanH

Views

5129

Build Author

EvanH

Views

5129

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Leboeuf

Views

5119

Build Author

Leboeuf

Views

5119

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Build Author

Vegard Humlen

Views

5116

Build Author

Vegard Humlen

Views

5116

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

Build Author

Charles Roseberry

Views

5112

Build Author

Charles Roseberry

Views

5112

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

Piggy back engraver for ShopBot

Built from leftover T-Slot extrusions plates and hardware from other defunct projects.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Makerparts Mpro Slider System

Makerparts.ca MPro Camera Slider System

My Lead 1010

This is a fully loaded Lead 1010 and located in a shed measuring 3 by 2.50 meters. Here i build my guiyats by hand and the help of my Openbuilds friend! Pure for hobby.

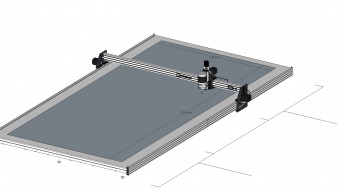

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

eddyg

Views

5053

Build Author

eddyg

Views

5053

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

ROUX - A Routy-OX Hybrid

ROUX is a 2'x4' CNC that can be easily handbuilt without an existing mill and removes the need to buy generic plates for the Routy. A simpler, more refined machine.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Brewery tank supports

Trying to design modular and evolutive supports for my brewery tanks.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

C beam xl

I would recommend this challenge to any woodworker looking for something new.

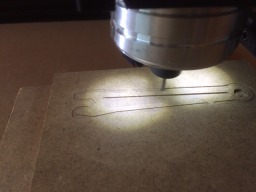

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

Craig Hollabaugh

Views

4997

Build Author

Craig Hollabaugh

Views

4997

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Skoobs

Views

4996

Build Author

Skoobs

Views

4996

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Build Author

RSch

Views

4985

Build Author

RSch

Views

4985

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Leveling Gantry

Large leveling platform to hold a 3hp router

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

Build Author

Bikes and Beer

Views

4952

Build Author

Bikes and Beer

Views

4952

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

James Evanko

Views

4941

Build Author

James Evanko

Views

4941

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

AVR SMD Daughter Board

SMD AVR Solderless Daughter Board

Build Author

Power Playground

Views

4906

Build Author

Power Playground

Views

4906

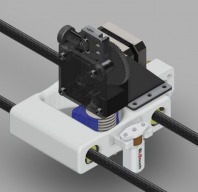

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

large format printer

I am hoping to post a detailed build of my printer it is a large format using the RepRap RAMPS 1.4 & Mega 2560 & DRV8825 Driver + optical end stop +LCD 12864 -C 0.4mm Far-end Distal Dual-Head Nozzle Extruder Double Nozzle

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Build Author

Robert J Rissell

Views

4853

Build Author

Robert J Rissell

Views

4853

Remix of Sage's Delta-Six

I'm looking to build a large build-volume, accurate, steady 3D printer with the eventual aim of swapping in a diode laser to allow for use as a cutter for printing/cutting parts out of balsa sheet for building model aircraft.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

cory stafford

Views

4821

Build Author

cory stafford

Views

4821

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Heavy Metal

CNC Mill built for cutting metal.

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

Build Author

OpenBuilds

Views

4806

Build Author

OpenBuilds

Views

4806

Interface magnetic mount

A simple build that helps you to mount the OpenBuilds Interface to the front of your machine.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

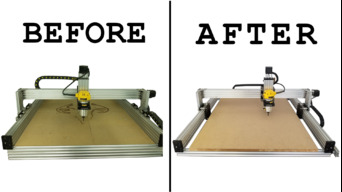

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

GhettoPrinter

Dirt cheap build.

Build Author

cnc-trucker

Views

4738

Build Author

cnc-trucker

Views

4738

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

Leon Style

Views

4721

Build Author

Leon Style

Views

4721

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Limine3D

Views

4686

Build Author

Limine3D

Views

4686

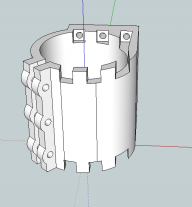

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

1.3m x 1.3m RF laser cutter

RF 100w laser cutter build, aluminium extrusion

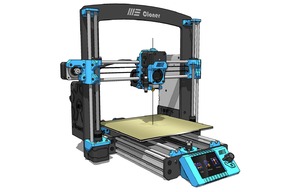

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

Build Author

Denis Lapratte

Views

4666

Build Author

Denis Lapratte

Views

4666

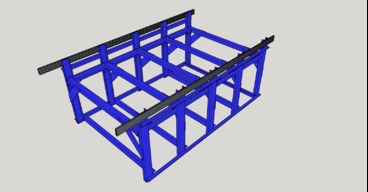

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

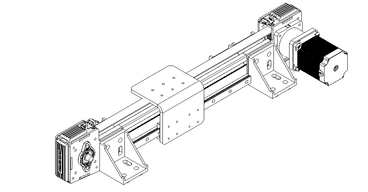

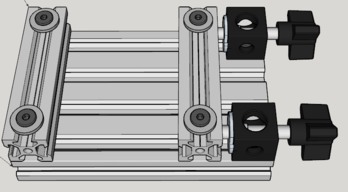

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Build Author

Cosmosteel

Views

4653

Build Author

Cosmosteel

Views

4653

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

jz321

Views

4633

Build Author

jz321

Views

4633

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Kossel Mini Delta

This is a Chinese kit I got on ebay from someone in CA.

cnc back stop for brake press

back stop build

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Build Author

stepper

Views

4610

Build Author

stepper

Views

4610

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Build Author

Cortellini

Views

4600

Build Author

Cortellini

Views

4600

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

Build Author

Dave Pyatt

Views

4587

Build Author

Dave Pyatt

Views

4587

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

ShockingTops

Views

4555

Build Author

ShockingTops

Views

4555

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

DaleShaw

Views

4555

Build Author

DaleShaw

Views

4555

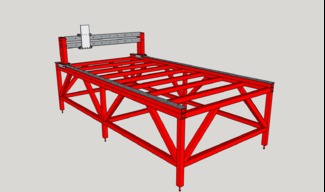

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

20x60 to Dewalt 611 Mount (a.k.a the Rook)

Dewalt 611 Router mount for mounting onto 20x60 v-slot