CNC ROUTER BUILDS

Build Author

alex_b

Views

17230

Build Author

alex_b

Views

17230

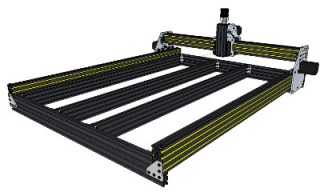

RONIN OX | The G10/Carbon Fiber Hogger

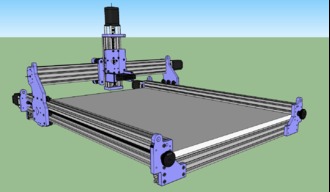

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

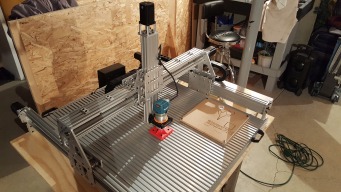

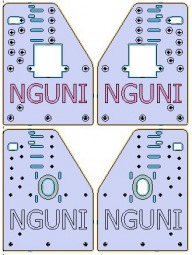

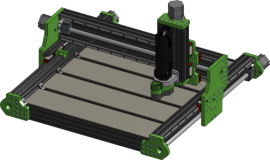

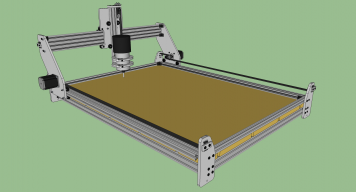

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

SlyClockWerkz

Views

16917

Build Author

SlyClockWerkz

Views

16917

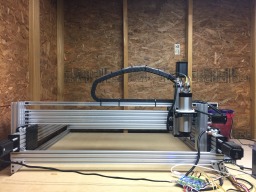

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Build Author

Ronald van Arkel

Views

16635

Build Author

Ronald van Arkel

Views

16635

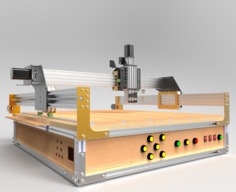

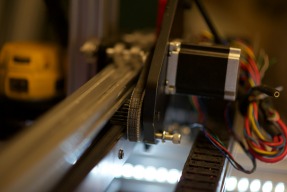

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

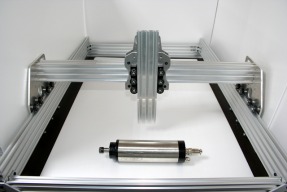

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

C-CNC

Views

16247

Build Author

C-CNC

Views

16247

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Build Author

CharlieShimota

Views

16235

Build Author

CharlieShimota

Views

16235

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

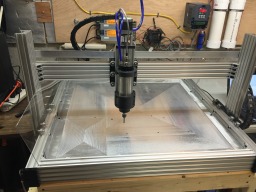

Aluminum OX build with some modifications

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!

Build Author

CubeSpawn

Views

16101

Build Author

CubeSpawn

Views

16101

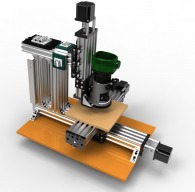

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

Build Author

Teflon4

Views

15950

Build Author

Teflon4

Views

15950

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Tool position setting Part III.

In this, the final part, I would like to introduce Machine Vision and show how it can be used, not only for tool position setting but also for resolving the triangle to calculate the G68 (local system rotated) for jobs which are not squarely placed on the work table.

Build Author

Janis93

Views

15716

Build Author

Janis93

Views

15716

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

Steve B

Views

15714

Build Author

Steve B

Views

15714

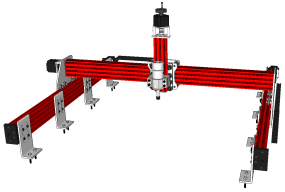

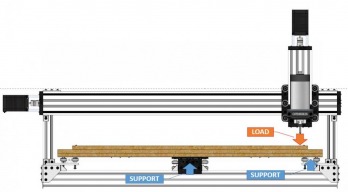

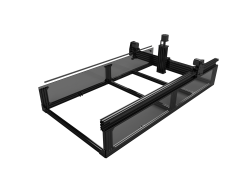

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

spunks.cam

Design of a multifunctional CNC machine.

Build Author

Rick Holder

Views

15441

Build Author

Rick Holder

Views

15441

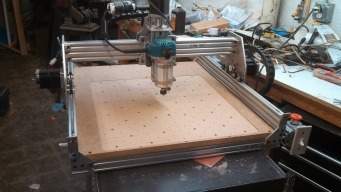

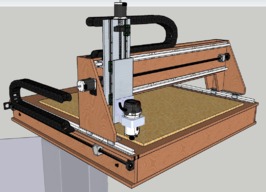

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

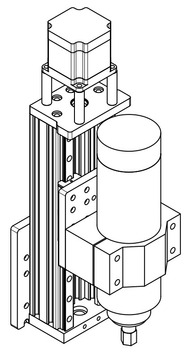

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Build Author

AK-Creation

Views

14961

Build Author

AK-Creation

Views

14961

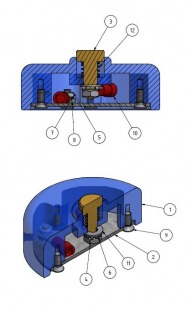

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

Joe Young

Views

14861

Build Author

Joe Young

Views

14861

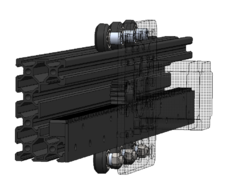

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Mark Carew

Views

14815

Build Author

Mark Carew

Views

14815

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

C-Beam to C-Beam XL Upgrade

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Build Author

Metalguru

Views

14694

Build Author

Metalguru

Views

14694

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Dave420

Views

14662

Build Author

Dave420

Views

14662

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

Build Author

GinoTheCop

Views

14632

Build Author

GinoTheCop

Views

14632

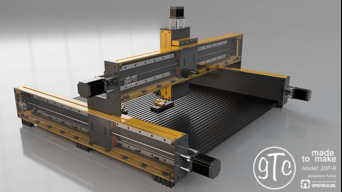

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

Project Hopeless

Views

14481

Build Author

Project Hopeless

Views

14481

Plywood Built CNC Router

This is my first build attempt, a large form (4x4ft.) 3 axis 4-motor CNC router table, . The build components are Baltic birch plywood, stepper motors, SBR linear bearings, and ball screws, LinuxCNC, Mesa controller.

Build Author

Savvas

Views

14430

Build Author

Savvas

Views

14430

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

JWhitten

Views

14140

Build Author

JWhitten

Views

14140

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

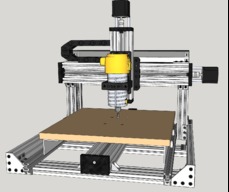

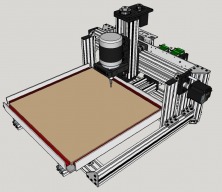

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

andrew Adsit

Views

14064

Build Author

andrew Adsit

Views

14064

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

Build Author

Ryan155

Views

14033

Build Author

Ryan155

Views

14033

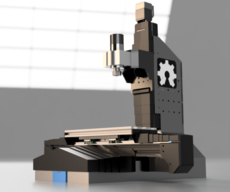

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Sword66

Views

14005

Build Author

Sword66

Views

14005

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

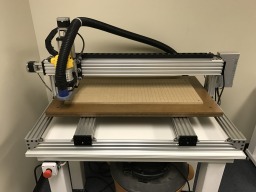

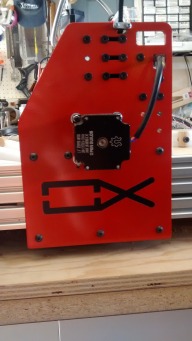

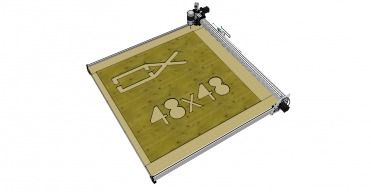

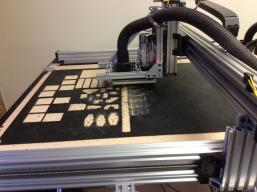

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

Build Author

Rob Mahan

Views

13779

Build Author

Rob Mahan

Views

13779

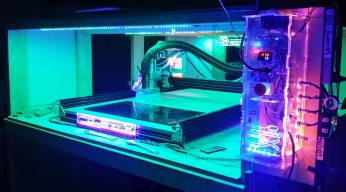

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Openbuilds C-beam

This is a build supported by Ooznest by a team of girls in Year 8 (12/13 years old) to machine model F1 cars for the F1 in Schools competition.

Build Author

Joey Selzler

Views

13556

Build Author

Joey Selzler

Views

13556

My JGro CNC becomes an OpenBuild Project

This is the story of my progression from the JGRO cnc router design to using the OpenBuild system. In the process I think I have learned some things about cnc routers and the accuracy required to make a good build.

Build Author

Nugz

Views

13527

Build Author

Nugz

Views

13527

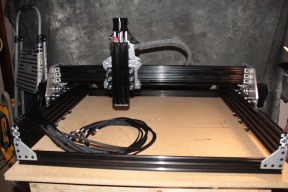

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

Build Author

signzonepr

Views

13039

Build Author

signzonepr

Views

13039

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

chenderson

Views

12865

Build Author

chenderson

Views

12865

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Nebraska 1246 x 1184

This is my first attempt at a CNC anything build

Build Author

JP Warnke

Views

12836

Build Author

JP Warnke

Views

12836

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Build Author

ymilord

Views

12733

Build Author

ymilord

Views

12733

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

My Ox

What I want to build is a unit to: rout wood, plastic and occasional aluminium . to be able to swap cutters. i.e. drragknife, laser, router, drill

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Build Author

inhan

Views

12600

Build Author

inhan

Views

12600

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

Build Author

nickchnv

Views

12589

Build Author

nickchnv

Views

12589

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12565

Build Author

AndersFaust

Views

12565

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

Build Author

GDanger117

Views

12360

Build Author

GDanger117

Views

12360

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Matt Nelson

Views

12322

Build Author

Matt Nelson

Views

12322

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

Build Author

jamesdjadams

Views

12250

Build Author

jamesdjadams

Views

12250

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

Scott Martinez

Views

12196

Build Author

Scott Martinez

Views

12196

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

pedrofernandez

Views

12183

Build Author

pedrofernandez

Views

12183

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

John J Talavera

Views

12180

Build Author

John J Talavera

Views

12180

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Build Author

Andrew Helsel

Views

12180

Build Author

Andrew Helsel

Views

12180

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

SandeepsCNC

Views

12171

Build Author

SandeepsCNC

Views

12171

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

Promoveo Study Builds

Promoteo Build

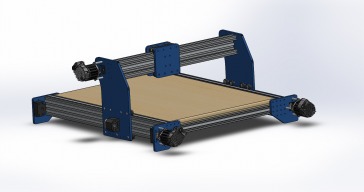

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

reef

Views

12015

Build Author

reef

Views

12015

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

Andreas Bockert

Views

12010

Build Author

Andreas Bockert

Views

12010

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

that-jim

Views

11931

Build Author

that-jim

Views

11931

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

sw3Dp

Views

11839

Build Author

sw3Dp

Views

11839

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

Build Author

Joe Garritano

Views

11700

Build Author

Joe Garritano

Views

11700

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

evil2002usna

Views

11574

Build Author

evil2002usna

Views

11574

Evil Ox

Cheap Ballscrew Ox CNC Router.

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

Build Author

dreys

Views

11430

Build Author

dreys

Views

11430

Was once a mini mill

Working progress.

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

Build Author

Yanou Fishel

Views

11396

Build Author

Yanou Fishel

Views

11396

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Ooznest OX CNC Build

Ooznest OX CNC build

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Build Author

Mike Campbell

Views

11142

Build Author

Mike Campbell

Views

11142

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

Bear

Views

11064

Build Author

Bear

Views

11064

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm