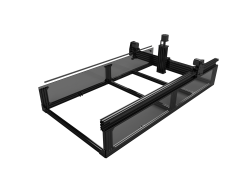

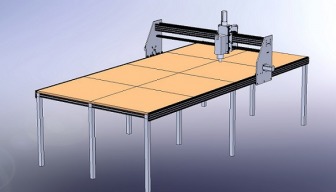

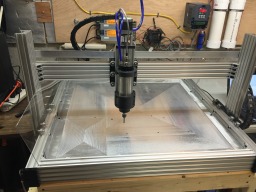

Cartesian Style CNC

Build Author

Apothus

Views

22517

Build Author

Apothus

Views

22517

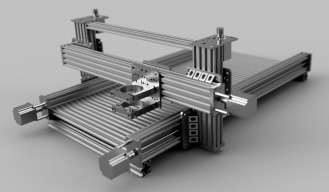

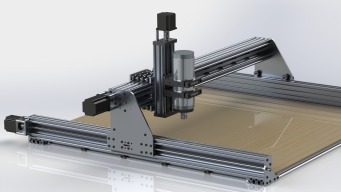

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

CharlieShimota

Views

16243

Build Author

CharlieShimota

Views

16243

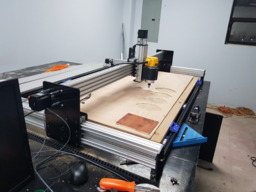

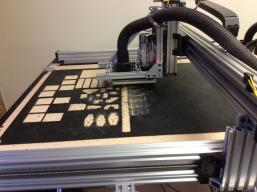

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

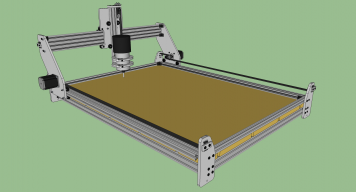

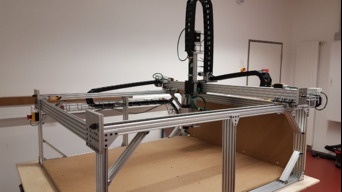

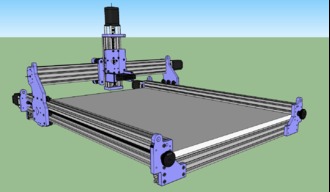

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Andreas Bockert

Views

12027

Build Author

Andreas Bockert

Views

12027

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Small Red OX

A small router for thin plate stock

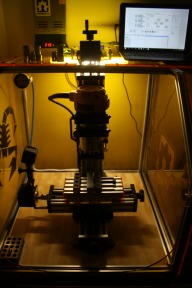

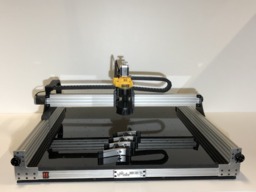

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Build Author

chenderson

Views

12872

Build Author

chenderson

Views

12872

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

Build Author

Joerharris

Views

6573

Build Author

Joerharris

Views

6573

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

GDanger117

Views

12379

Build Author

GDanger117

Views

12379

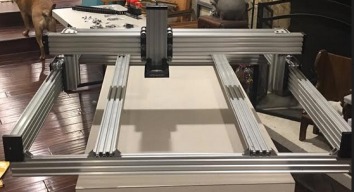

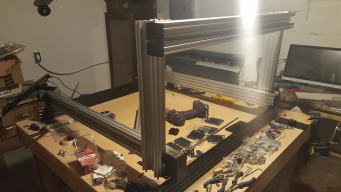

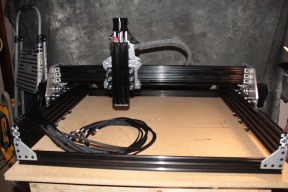

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

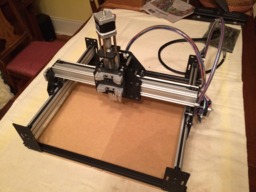

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

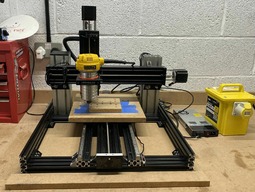

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Build Author

GinoTheCop

Views

14636

Build Author

GinoTheCop

Views

14636

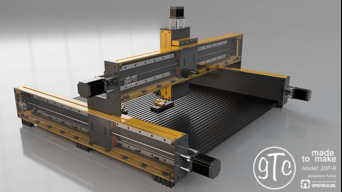

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

Corey Corbin

Views

7634

Build Author

Corey Corbin

Views

7634

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

CNCGear

Views

10672

Build Author

CNCGear

Views

10672

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

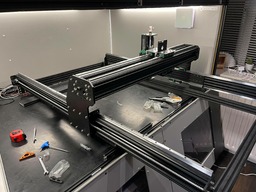

Desktop CNC

A desktop Cartesian CNC router

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Contrariwise -- A C-Beam Router

A C-Beam router made almost entirely of standard parts. Electronics include an xPro v2 board and NEMA 23 motors. Cuts are made with a small 300W DC spindle. A pressure foot is used to minimize the need for workholding.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

Hisha

Views

8884

Build Author

Hisha

Views

8884

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Lasersc

Views

10477

Build Author

Lasersc

Views

10477

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

reef

Views

12031

Build Author

reef

Views

12031

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

My build

I am satisfied with my build and next one will be even better.

Build Author

Kenneth Witthuhn

Views

8511

Build Author

Kenneth Witthuhn

Views

8511

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Aluminum OX build with some modifications

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!

My Ox

What I want to build is a unit to: rout wood, plastic and occasional aluminium . to be able to swap cutters. i.e. drragknife, laser, router, drill

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

C-beam Router rack and pinion

I want build a frame that is as sturdy as possibility while at the same time keeping it as compact as possible. working area will be approx 1200mm x 600mm

Build Author

evildean

Views

8916

Build Author

evildean

Views

8916

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Tucstrlly

Views

9098

Build Author

Tucstrlly

Views

9098

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Dave Pyatt

Views

4525

Build Author

Dave Pyatt

Views

4525

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

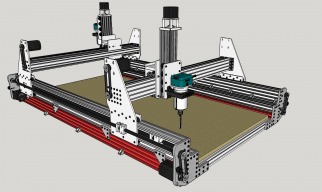

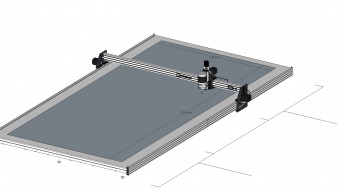

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Build Author

Joe F

Views

8530

Build Author

Joe F

Views

8530

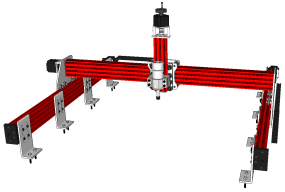

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Long Ox with drop in table

This build is a modified Ox build. The long rails are 1000mm. My build includes a solid clamping table.

OX-LX-3D

An OX build - little large than specs and plates 3D printed

Build Author

Rural

Views

26051

Build Author

Rural

Views

26051

OS OX

Mechanically, a scaled up OX build (1500x1500). Electronically, GRBL on an Arduino and a gShield. From a software perspective, the focus is on useable open source software tool chains.

Nebraska 1246 x 1184

This is my first attempt at a CNC anything build

OX Build

Standard OX Build

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12577

Build Author

AndersFaust

Views

12577

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

andrew Adsit

Views

14077

Build Author

andrew Adsit

Views

14077

OX Cable Management, Electronics Case, E-Stops

750mm x 750mm OX build, xPro V2 controller, 400W Spindle with PWM controller.

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Build Author

Robert Bailey

Views

29421

Build Author

Robert Bailey

Views

29421

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

Rwetzler

Views

9400

Build Author

Rwetzler

Views

9400

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Build Author

JP Warnke

Views

12839

Build Author

JP Warnke

Views

12839

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Huub65

Views

9321

Build Author

Huub65

Views

9321

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Brokkr CNC 2.0

1M C-beam xy variant

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Build Author

TurfnSurf

Views

7157

Build Author

TurfnSurf

Views

7157

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Bikes and Beer

Views

4884

Build Author

Bikes and Beer

Views

4884

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

mathom713

Views

9639

Build Author

mathom713

Views

9639

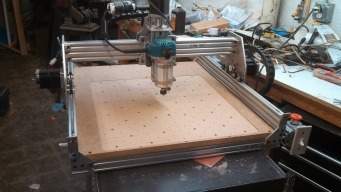

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Build Author

Shaun Weitzel

Views

7521

Build Author

Shaun Weitzel

Views

7521

OpenBuilds Lead 1515

First build of a Lead 1515!

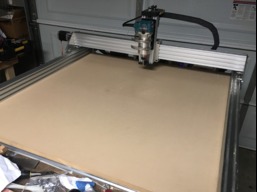

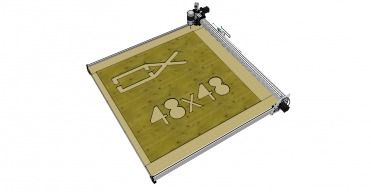

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

The Buffalo

OX 1500 x 1000 mm

Build Author

Kermareg

Views

17370

Build Author

Kermareg

Views

17370

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

1200 x 2700 CNC based on OX

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Laurence Carroll

Views

10976

Build Author

Laurence Carroll

Views

10976

C-Beam Double X

Per the special notes its a variant of the C-Beam, Machine.... I have noticed that alot of people build a CNC router to cut parts for other larger CNC machines.. eg Delta Printers etc....plus this will enable me to cut parts for model RC plans UAV's etc...

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Jesse Jenkins

Views

9423

Build Author

Jesse Jenkins

Views

9423

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Maxime Favre

Views

9538

Build Author

Maxime Favre

Views

9538

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe