Build List

-

Active Filters:

ac

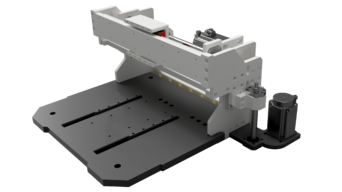

cnc back stop for brake press

back stop build

Build Author

sausagePaws

Views

79676

Build Author

sausagePaws

Views

79676

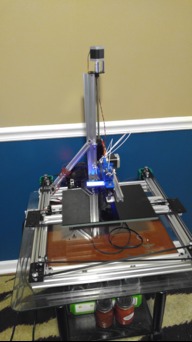

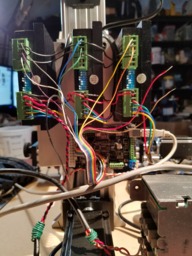

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

T4Concepts

Views

81107

Build Author

T4Concepts

Views

81107

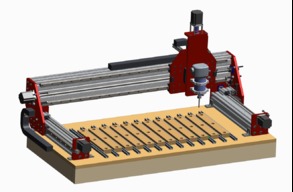

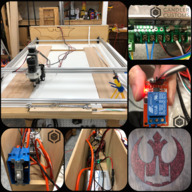

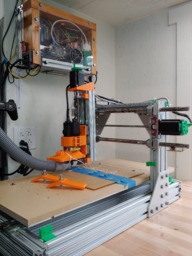

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

Ryan Lock

Views

136235

Build Author

Ryan Lock

Views

136235

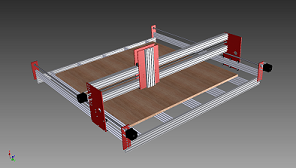

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Build Author

ymilord

Views

59718

Build Author

ymilord

Views

59718

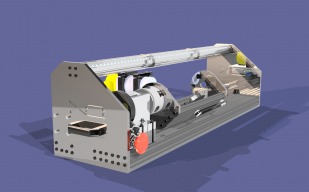

FARM OX (Four Axis Rotary Machine)

Four Axis Rotary Machine (FARM) OX. Equipped with a X,Z,A & C Axis.

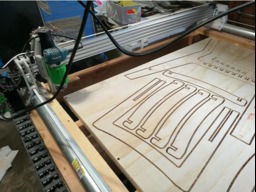

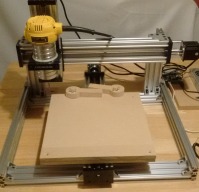

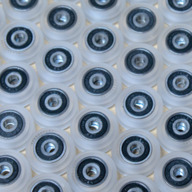

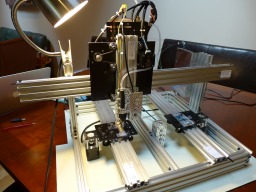

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

Build Author

pedrofernandez

Views

39197

Build Author

pedrofernandez

Views

39197

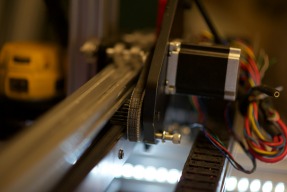

Openbuilds Table Top 50w Co2 Laser Cutter/Engraver

DIY build of a Co2 Laser cutter/engraver 12x24 working area.

Build Author

Mark Carew

Views

1209114

Build Author

Mark Carew

Views

1209114

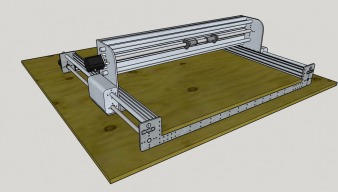

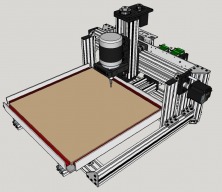

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

Keith Davis

Views

35444

Build Author

Keith Davis

Views

35444

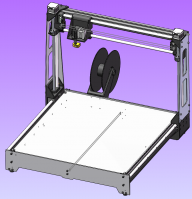

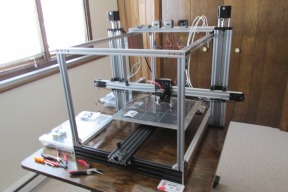

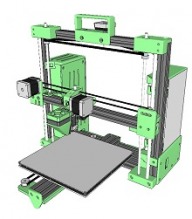

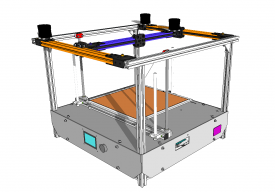

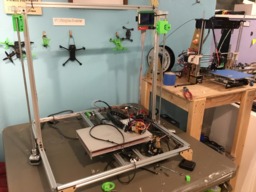

OneZ i3

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

Build Author

Schematix

Views

158105

Build Author

Schematix

Views

158105

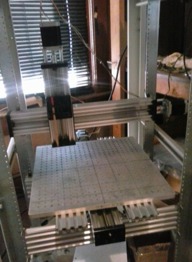

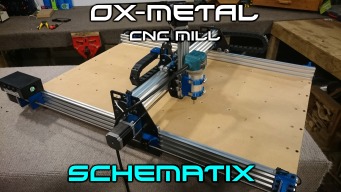

OX-Metal CNC Router Mill

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

Build Author

sausagePaws

Views

1759818

Build Author

sausagePaws

Views

1759818

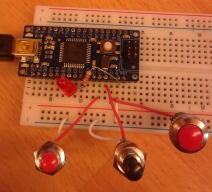

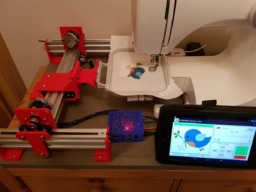

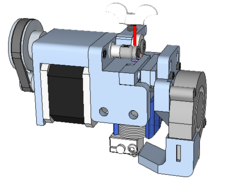

DIY Embroidery Machine V2

My second attempt at an affordable sewing machine embroidery add on. This one uses readily available electronics modules and 3D printable parts where possible.

Build Author

pedrofernandez

Views

15262

Build Author

pedrofernandez

Views

15262

The Franken Forty

This is a K40 machine conversion!!

Build Author

Mark Carew

Views

127058

Build Author

Mark Carew

Views

127058

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Ronald van Arkel

Views

16623

Build Author

Ronald van Arkel

Views

16623

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

ymilord

Views

12720

Build Author

ymilord

Views

12720

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Build Author

Gerald Klein

Views

17273

Build Author

Gerald Klein

Views

17273

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

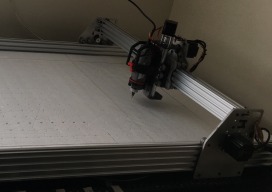

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Denford CNC Resurrection

Denford CNC Mill Update

Build Author

Mark Carew

Views

108965

Build Author

Mark Carew

Views

108965

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

OpenBuilds

Views

29577

Build Author

OpenBuilds

Views

29577

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

Mark Carew

Views

93091

Build Author

Mark Carew

Views

93091

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Build Author

Bobnet

Views

13357

Build Author

Bobnet

Views

13357

Rackmount + OpenRail

OpenRail attached to a 19" rackmount 15U box.

Build Author

John J Talavera

Views

12174

Build Author

John J Talavera

Views

12174

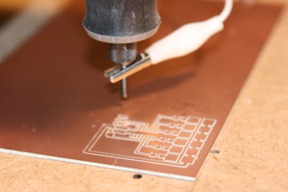

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Build Author

CubeSpawn

Views

16094

Build Author

CubeSpawn

Views

16094

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

Mohsen Abbasi

Views

8959

Build Author

Mohsen Abbasi

Views

8959

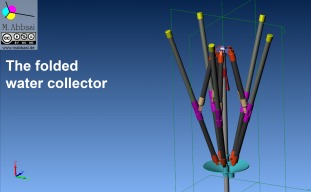

Foldable Rainwater Collector

Realisation of my idea about a foldable collector for rainwater, which is light and easy to make. People around the world need water and can collect rain water with this collector. I made it for syria and all too.

USB Pendant

An USB Pendant for LinuxCNC / Mach3

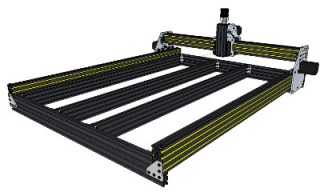

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Build Author

Nugz

Views

13516

Build Author

Nugz

Views

13516

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Hybrid OX (Ball Screw, Linear Guides, Ect.)

Planning my first build. Hope to achieve a larger format yet rigid design.

Build Author

Steve hope

Views

19218

Build Author

Steve hope

Views

19218

8x4 CNC build

Routy cnc upgrade.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

CWidt

Views

8725

Build Author

CWidt

Views

8725

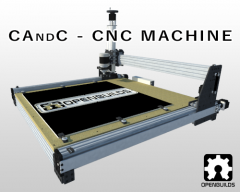

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

Build Author

JoeH

Views

7658

Build Author

JoeH

Views

7658

COTSPnP

The COTSPnP pick-and-place machine (PnP) is used to place surface-mount devices (SMDs) onto a printed circuit board and was designed and built exclusively from off-the-shelf (COTS) components, predominantly sourced from OpenBuilds and Actobotics. Its intended use is prototyping and not high rate, high volume production and is capable of precisely placing parts as small as 0402 capacitors and resistors but more importantly, can precisely place components with lead spacing as small a 0.4mm.

Build Author

Anglesachse

Views

9053

Build Author

Anglesachse

Views

9053

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

Ooznest Moded CNC

Modded OX with full nema23 4 point support

My Little OX

This build has been an educational experience. Software and hardware alike.

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

Peter Oakes

Views

44281

Build Author

Peter Oakes

Views

44281

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

Build Author

zann68

Views

9303

Build Author

zann68

Views

9303

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6184

Build Author

Gary Bonard

Views

6184

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Julius

Views

8206

Build Author

Julius

Views

8206

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

My Second CNC

In short...this was a fun project.

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Build Author

Rob Taylor

Views

20217

Build Author

Rob Taylor

Views

20217

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Build Author

Metalguru

Views

14678

Build Author

Metalguru

Views

14678

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

boubouexpress

Views

11514

Build Author

boubouexpress

Views

11514

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

Build Author

Jose A. Molina

Views

7014

Build Author

Jose A. Molina

Views

7014

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Krishnakumar

Views

8737

Build Author

Krishnakumar

Views

8737

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

crystaldragon141

Views

6573

Build Author

crystaldragon141

Views

6573

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Build Author

Ken376

Views

3747

Build Author

Ken376

Views

3747

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

dodgenet

Views

6602

Build Author

dodgenet

Views

6602

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

Build Author

Dmknerr

Views

5219

Build Author

Dmknerr

Views

5219

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Chetan PM

Views

3816

Build Author

Chetan PM

Views

3816

Composer

Gantry style rigid build

Build Author

Peter Van Der Walt

Views

7448

Build Author

Peter Van Der Walt

Views

7448

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

Tomas F Uribe

Views

5341

Build Author

Tomas F Uribe

Views

5341

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

megashub

Views

24273

Build Author

megashub

Views

24273

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

SecretSpy711

Views

22578

Build Author

SecretSpy711

Views

22578

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

Tucstrlly

Views

9082

Build Author

Tucstrlly

Views

9082

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

New 2 watt laser platform

Acro based 2 watt laser platform

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Lindsey Lewis

Views

8175

Build Author

Lindsey Lewis

Views

8175

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

ZacharyB

Views

5763

Build Author

ZacharyB

Views

5763

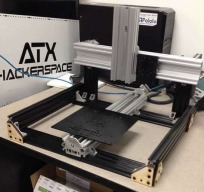

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Dave Pyatt

Views

4512

Build Author

Dave Pyatt

Views

4512

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2830

Build Author

Terone Burgenheim

Views

2830

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6443

Build Author

Terone Burgenheim

Views

6443

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8443

Build Author

Carl van Heezik

Views

8443

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

cory stafford

Views

4783

Build Author

cory stafford

Views

4783

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

MidnightQuads

Views

3907

Build Author

MidnightQuads

Views

3907

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12343

Build Author

GDanger117

Views

12343

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

9005

Build Author

Lindsey Lewis

Views

9005

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5449

Build Author

Keith Davis

Views

5449

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3780

Build Author

George Motichka

Views

3780

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

6051

Build Author

RJ_Make

Views

6051

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5559

Build Author

CandlerCustoms

Views

5559

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5807

Build Author

Sam Price

Views

5807

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Camvec

Views

6272

Build Author

Camvec

Views

6272

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

Rodrigo Gonzalez

Views

3631

Build Author

Rodrigo Gonzalez

Views

3631

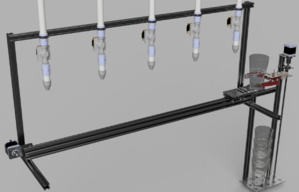

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Bill325

Views

2339

Build Author

Bill325

Views

2339

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

OffAxis

Views

7732

Build Author

OffAxis

Views

7732

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Nicademus

Views

9564

Build Author

Nicademus

Views

9564

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

5102

Build Author

Rob Withoff

Views

5102

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

TurfnSurf

Views

6215

Build Author

TurfnSurf

Views

6215

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

JAC_101

Views

6080

Build Author

JAC_101

Views

6080

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

MattR

Views

20311

Build Author

MattR

Views

20311

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.