Build List

-

Active Filters:

ac

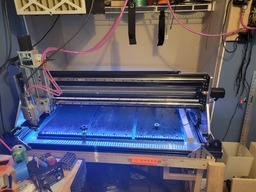

CO2 100W Laser Machine with 1600*1800mm Field

I have been assembling various machines for a long time, more than 30 pieces have already been assembled, so I decided to post one of the recent projects. CO2 laser machine with a power of 100 watts, the size of the working field is 1600 width and 1800 length.

Build Author

naltek

Views

837

Build Author

naltek

Views

837

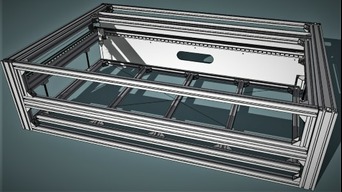

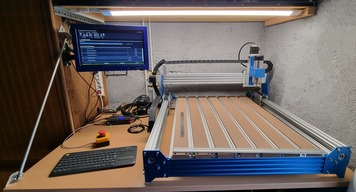

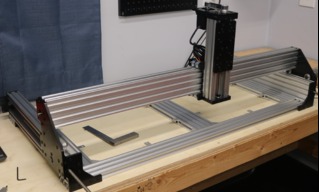

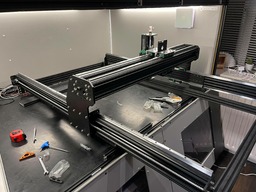

NALCNC: New Open-Source High-Performance Modular CNC System | Large Format Kits & Machines

NALCNC: New Open-Source High-Performance Modular CNC System (MPCNC Evolution) – Large Format Kits & Machines

My build

I am satisfied with my build and next one will be even better.

Build Author

Alain JBT

Views

1289

Build Author

Alain JBT

Views

1289

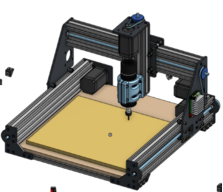

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.

Build Author

Mark Carew

Views

14253

Build Author

Mark Carew

Views

14253

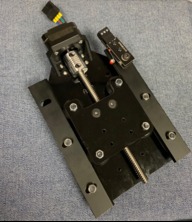

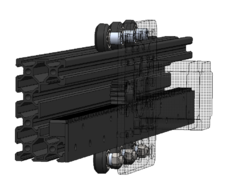

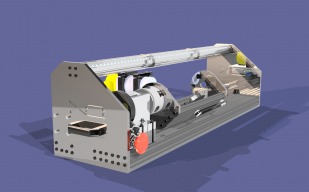

C-Beam® Double Wide Gantry Actuator

This easy to build actuator is configured to have not only strength, but accuracy! This low profile option offers endless possibilities, and we cant wait to see how this actuator is implemented in your build ideas!

Build Author

BCulbertson

Views

5648

Build Author

BCulbertson

Views

5648

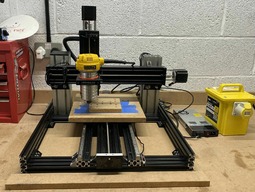

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

sausagePaws

Views

80170

Build Author

sausagePaws

Views

80170

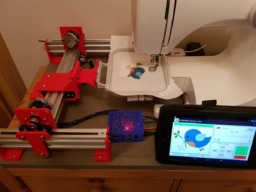

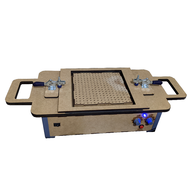

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

cdsmith12

Views

50292

Build Author

cdsmith12

Views

50292

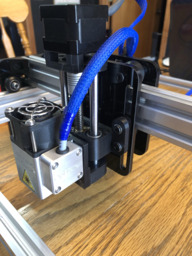

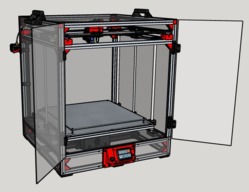

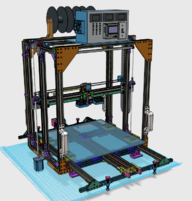

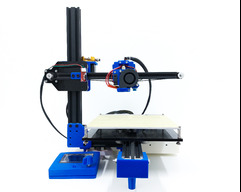

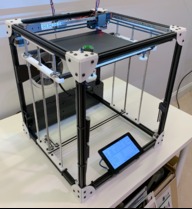

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

Mark Carew

Views

109716

Build Author

Mark Carew

Views

109716

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

Mark Carew

Views

65493

Build Author

Mark Carew

Views

65493

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Workbee 1010 et laser atomstack M100

Je ne sais pas comment brancher mon laser sur la blackbox?

Build Author

OpenBuilds

Views

32914

Build Author

OpenBuilds

Views

32914

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

Build Author

OpenBuilds

Views

6236

Build Author

OpenBuilds

Views

6236

A1 ACRO Draw Bot

We created an A1 ACRO Drawing robot specifically for the artist communities. It utilizes the popular ISO 'A series' paper sizes standards

Build Author

Mark Carew

Views

271592

Build Author

Mark Carew

Views

271592

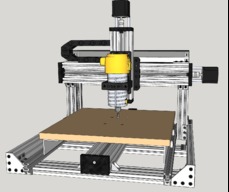

C-Beam® Machine - Plate Maker

This C-beam Machine is an in affordable CNC plate maker and 3D carving machine!

Build Author

Alexander_Bulgaria

Views

1812

Build Author

Alexander_Bulgaria

Views

1812

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

cnc back stop for brake press

back stop build

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

OpenBuilds ACRO Z Axis

Z-Axis for OpenBuilds ACRO system. It is sturdy enough to carry a small drill.

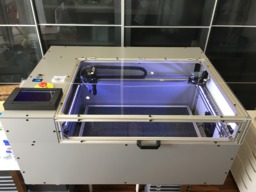

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Build Author

David E. Flores E.

Views

8402

Build Author

David E. Flores E.

Views

8402

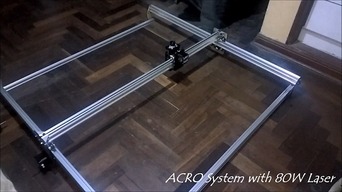

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

Hot Wire 4 Axis CNC Foam cutter

This build uses drawer slides and thread rod to create foam wings and fuselages by passing a hot wire through the foam which makes very accurate shapes. I built a Radio Controlled SuperVC10 using foam but did have a cnc machine then so I had to make many templates to guide the hot wire. This inspired me to build a cnc hot wire cutter. Works really well and have made several RC models with it now

Build Author

Mark Carew

Views

18634

Build Author

Mark Carew

Views

18634

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Mark Carew

Views

28117

Build Author

Mark Carew

Views

28117

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Mark Carew

Views

18660

Build Author

Mark Carew

Views

18660

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Joe Young

Views

15123

Build Author

Joe Young

Views

15123

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Quentin Karmark

Views

9734

Build Author

Quentin Karmark

Views

9734

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

OpenBuilds

Views

30148

Build Author

OpenBuilds

Views

30148

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

Bob Darrow

Views

10342

Build Author

Bob Darrow

Views

10342

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Build Author

Mark Carew

Views

91001

Build Author

Mark Carew

Views

91001

BlackBox Motion Control System

The Openbuilds BlackBox is a new system evolved around a set of subsystems that cover more than just control and also more than just CNC type applications! With a plug-and-play easy connection system this controller can be used with ease, without sacrificing power.

Build Author

Kyo

Views

29076

Build Author

Kyo

Views

29076

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Build Author

Mark Carew

Views

127969

Build Author

Mark Carew

Views

127969

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Build Author

Ryan Lock

Views

146726

Build Author

Ryan Lock

Views

146726

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

Mark Carew

Views

68811

Build Author

Mark Carew

Views

68811

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

Build Author

Ryan Lock

Views

136824

Build Author

Ryan Lock

Views

136824

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Build Author

Gerald Klein

Views

17563

Build Author

Gerald Klein

Views

17563

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Build Author

Kyo

Views

46334

Build Author

Kyo

Views

46334

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Build Author

alan richard

Views

51754

Build Author

alan richard

Views

51754

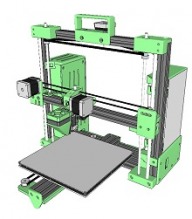

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Keith Davis

Views

35596

Build Author

Keith Davis

Views

35596

OneZ i3

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

Build Author

Mark Carew

Views

17307

Build Author

Mark Carew

Views

17307

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

OpenBuilds

Views

17735

Build Author

OpenBuilds

Views

17735

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

that-jim

Views

48285

Build Author

that-jim

Views

48285

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Build Author

Mark Carew

Views

78439

Build Author

Mark Carew

Views

78439

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

C-Beam Machine XLarge

A rigid and wide format, plate and carving CNC.

Build Author

Jason Moore

Views

13326

Build Author

Jason Moore

Views

13326

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Denford CNC Resurrection

Denford CNC Mill Update

Build Author

Cam Garrett

Views

4224

Build Author

Cam Garrett

Views

4224

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Build Author

Mark Carew

Views

1212935

Build Author

Mark Carew

Views

1212935

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

deltajegga

Views

10024

Build Author

deltajegga

Views

10024

THE delta

probably as big as you'd want it...

Build Author

Jasont

Views

4498

Build Author

Jasont

Views

4498

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Sonny Lowe

Views

7068

Build Author

Sonny Lowe

Views

7068

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Build Author

sausagePaws

Views

1761032

Build Author

sausagePaws

Views

1761032

DIY Embroidery Machine V2

My second attempt at an affordable sewing machine embroidery add on. This one uses readily available electronics modules and 3D printable parts where possible.

Build Author

nc3dpw

Views

24618

Build Author

nc3dpw

Views

24618

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

joetemus

Views

27948

Build Author

joetemus

Views

27948

K40 ACRO Conversion

A K40 to ACRO Co2 laser cutter build. Designed and built to expand the work area of the K40

Build Author

OpenBuilds

Views

12086

Build Author

OpenBuilds

Views

12086

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

Ahmed Ibrahim

Views

10188

Build Author

Ahmed Ibrahim

Views

10188

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

Build Author

blterry1

Views

19329

Build Author

blterry1

Views

19329

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

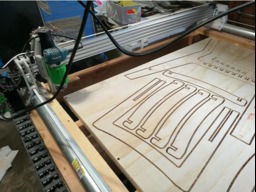

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

Build Author

Lindsey Lewis

Views

9122

Build Author

Lindsey Lewis

Views

9122

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

BeTrue3D

Views

22613

Build Author

BeTrue3D

Views

22613

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

LukasK

Views

24190

Build Author

LukasK

Views

24190

LS-LASER

I have completed some custom build 3d printers (i3 and delta style) and a cnc mill based on v-slot and c-beam. From the beginning the cnc was built to fit/change between router, 5w led laser module and plotter pen. While all three works great, the build is primarily focused on heavy duty milling and brings some disadvantages when it comes to laser - slow because of leadscrew motion system and not as powerful because of “only” led laser. That is why I have started this build of co2 laser machine.

Build Author

T4Concepts

Views

81927

Build Author

T4Concepts

Views

81927

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

pedrofernandez

Views

39574

Build Author

pedrofernandez

Views

39574

Openbuilds Table Top 50w Co2 Laser Cutter/Engraver

DIY build of a Co2 Laser cutter/engraver 12x24 working area.

Build Author

Glenn Weston

Views

11616

Build Author

Glenn Weston

Views

11616

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

ymilord

Views

60029

Build Author

ymilord

Views

60029

FARM OX (Four Axis Rotary Machine)

Four Axis Rotary Machine (FARM) OX. Equipped with a X,Z,A & C Axis.

Build Author

Martin.Barfoed

Views

7311

Build Author

Martin.Barfoed

Views

7311

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

Build Author

Mike Campbell

Views

11313

Build Author

Mike Campbell

Views

11313

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Prototype Rack-n-Pinion 4'x8'

This is a custom gear rack drive machine with a 4'x8' cut capacity.

Z Axis for ACRO

Created a small Z axis for the ACRO motion system. I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. Also wanted to be able to vary the height for multiple cutting passes on some materials. Try to stick to a similar aesthetic as the original ACRO system and plates.

Build Author

rengelking

Views

40667

Build Author

rengelking

Views

40667

Vacuum Forming Machine

Vacuum Former built with off-the-shelf parts, works perfectly every time!

Build Author

SOA

Views

64097

Build Author

SOA

Views

64097

GridBot Two: Powerfully Simple

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Black gear 1500X3000

My cnc update and rebuild.

Build Author

Mark Carew

Views

85926

Build Author

Mark Carew

Views

85926

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

lekey

Views

12456

Build Author

lekey

Views

12456

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

Build Author

Johnny Reich

Views

2182

Build Author

Johnny Reich

Views

2182

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

Build Author

OpenBuilds

Views

4833

Build Author

OpenBuilds

Views

4833

Interface magnetic mount

A simple build that helps you to mount the OpenBuilds Interface to the front of your machine.

DIY Vacuum Hold Down table

A simple vacuum hold down/clamp set up using a 6hp canister vacuum.

Pick and place

Pick and place based on the Openbuilds ACRO 20x20

Build Author

Mark Carew

Views

55342

Build Author

Mark Carew

Views

55342

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Pick and place

Openbuilds Pick and Place using ideas from OpenPNP Frame work is from the Openbuilds Part store using 1000mm C beams and vslot 40x40 for support Surface is 3/4 " Particle board

Build Author

theracermark

Views

4101

Build Author

theracermark

Views

4101

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

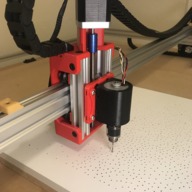

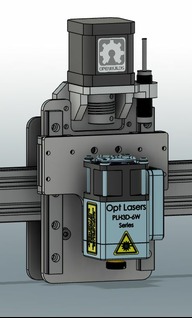

Z-Axis for Laser Diode

Custom Z Axis for OptLaser 6watt and the Acro System

Build Author

Jacob Christiansen

Views

7472

Build Author

Jacob Christiansen

Views

7472

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

Build Author

Stokrotka74

Views

7072

Build Author

Stokrotka74

Views

7072

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Laser engraving machine

Second better project, high durable mainframe, silent work, non vibration.

Build Author

CNCGear

Views

10871

Build Author

CNCGear

Views

10871

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

Mark Carew

Views

25780

Build Author

Mark Carew

Views

25780

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Sim Racing rig

Made with OpenBuilds 2020 and 2060 material/brackets/hardware. Simlabs wheel deck. Fanatec DD wheel base/wheel/pedals NRG seat Sim racing studio wind simulators Few 3D printed brackets/caps/cable holds

Laser cutter

Full aluminium profiles construction. Synrad 50w CO2 laser. Ruida controller. Yaskawa servo motors

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Build Author

Joe F

Views

8686

Build Author

Joe F

Views

8686

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.