Build List

-

Active Filters:

printer

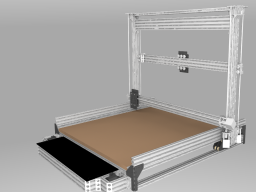

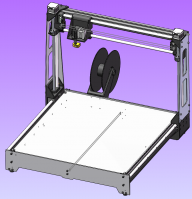

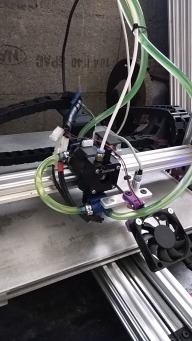

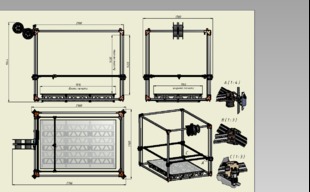

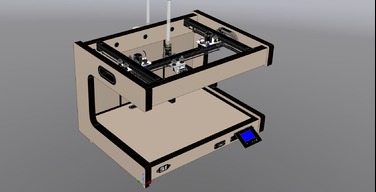

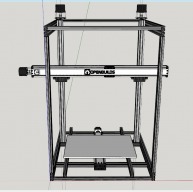

DoubleX

This is a Dual X-axis platform.

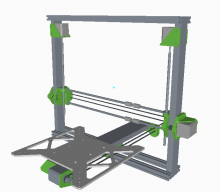

ALUMNO v1

It is a first draw of my future Printer/CNC cutter.PCB mill Still need to work more on it

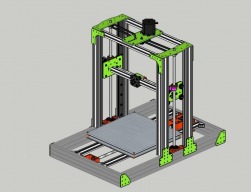

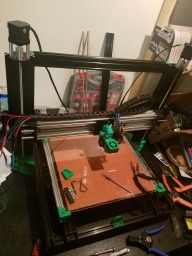

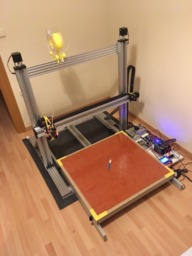

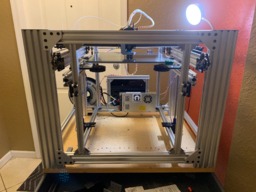

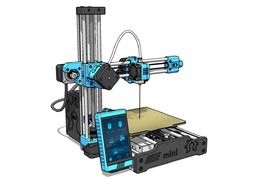

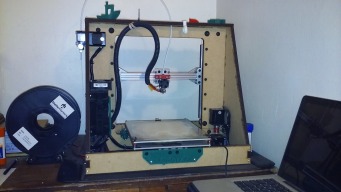

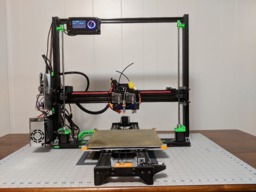

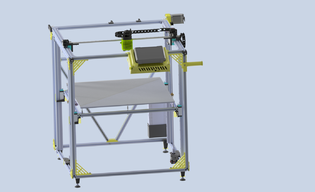

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

Build Author

jjcolletta

Views

11195

Build Author

jjcolletta

Views

11195

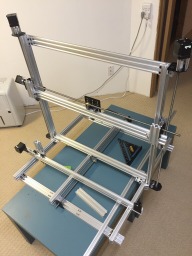

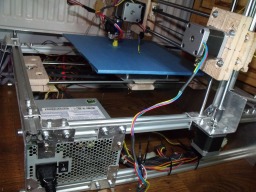

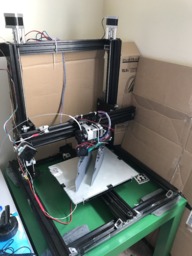

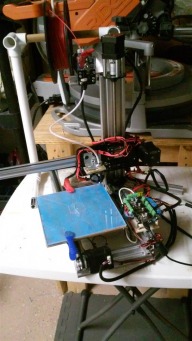

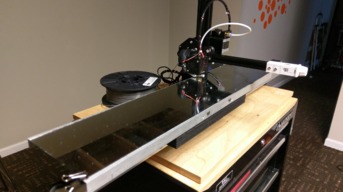

First 3d build

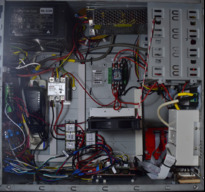

I am building a simple home brewed printer. I have a background in industrial automation so I figured how hard could this be. The mechanical build was pretty smooth as was the electrical side. Now just getting plastic out the hotend is my stopping point.

Build Author

CreativeTools

Views

9466

Build Author

CreativeTools

Views

9466

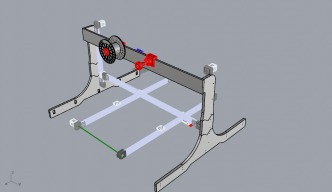

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

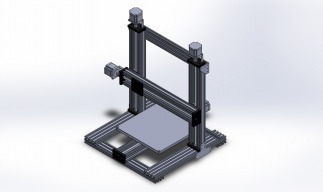

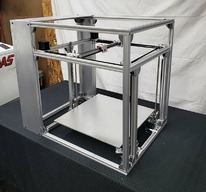

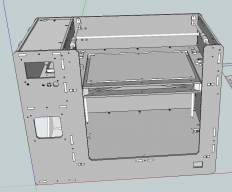

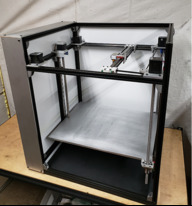

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

Build Author

Kermareg

Views

17352

Build Author

Kermareg

Views

17352

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

Build Author

adamcooks

Views

43325

Build Author

adamcooks

Views

43325

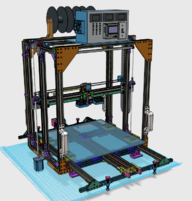

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

large format printer

I am hoping to post a detailed build of my printer it is a large format using the RepRap RAMPS 1.4 & Mega 2560 & DRV8825 Driver + optical end stop +LCD 12864 -C 0.4mm Far-end Distal Dual-Head Nozzle Extruder Double Nozzle

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

Bandicoot v1

My first custom build, using vslot rails for Z and Y and 8mm rails for X. Currently printing parts for this using my Prusa I3. The build volume will be roughly 300mm^3, X and Y are belt driven with 8mm acme lead screws for Z. Will be uploading more info shortly as i continue to build the printer.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

3 Axis MultiTool - 3D printer, CNC Mill and Plasma Cutter

So in short this build is a work in progress; it aims to make a large 3d printer, medium size CNC mill and a small plasma cutter all in one CNC unit.

Build Author

KBill

Views

13520

Build Author

KBill

Views

13520

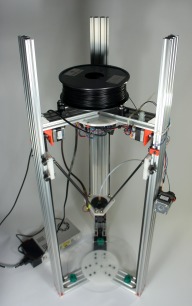

MIY OLY Delta Printer

Mag arm deltabot with laser cut carriages and connectors.

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

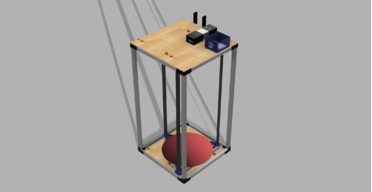

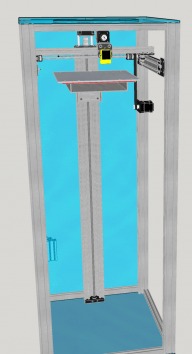

STEAM crane printer

The STEAM Crane 3d printer uses the new C-Beam linear rail. It is being developed for an after school / summer camp program for kids. All of the electronics are housed in the base and the wiring is routed down the channels of the c-beam. This is done to contain as much of the loose wiring as possible, hopefully keeping it safer for kids.

Build Author

openhardwarecoza

Views

9283

Build Author

openhardwarecoza

Views

9283

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

Mike Andrews

Views

9268

Build Author

Mike Andrews

Views

9268

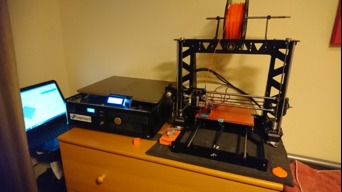

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

V Rail 3D printer

My version a Cartesian style 3d printer, an attempt to eliminate frame vibration and movement and to use up materials left over from other projects.

Build Author

Kaarbble

Views

10395

Build Author

Kaarbble

Views

10395

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

Build Author

DIY3DTech.com

Views

6509

Build Author

DIY3DTech.com

Views

6509

3D Printer Leveler Made with Maker Rail

Leveling Platform / Stand 3D Printers

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Build Author

Steve Marsh

Views

5748

Build Author

Steve Marsh

Views

5748

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

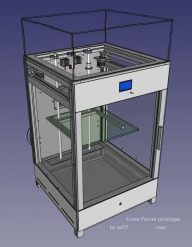

Tower Printer

Tower Printer H-Belt type printer Prototype

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

Build Author

Nwrgordon

Views

15889

Build Author

Nwrgordon

Views

15889

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Build Author

Cbrown330

Views

5374

Build Author

Cbrown330

Views

5374

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Build Author

Anthony Bolgar

Views

12024

Build Author

Anthony Bolgar

Views

12024

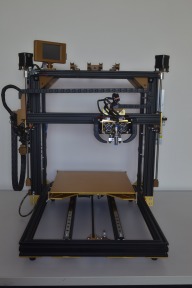

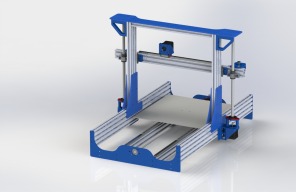

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

UltiBots

Views

10555

Build Author

UltiBots

Views

10555

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

griso

Views

9255

Build Author

griso

Views

9255

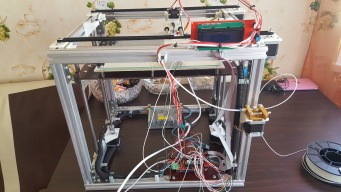

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Infinite Z Delta Printer

Currently completely imaginary

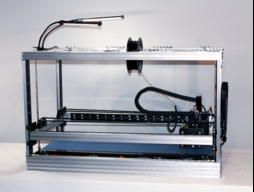

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Power Playground

Views

4836

Build Author

Power Playground

Views

4836

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

delta 3d printer kit

HE3D K200 kit build

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

Build Author

sgspenceley

Views

8953

Build Author

sgspenceley

Views

8953

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Build Author

dodgenet

Views

6587

Build Author

dodgenet

Views

6587

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

TouchPadKing

Views

5096

Build Author

TouchPadKing

Views

5096

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Build Author

Linkreincarnate

Views

3126

Build Author

Linkreincarnate

Views

3126

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Build Author

Kyo

Views

6516

Build Author

Kyo

Views

6516

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8573

Build Author

taratata2016

Views

8573

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8549

Build Author

Limine3D

Views

8549

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9136

Build Author

J-Wahl Dezign

Views

9136

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

nschreiber0813

Views

5472

Build Author

nschreiber0813

Views

5472

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

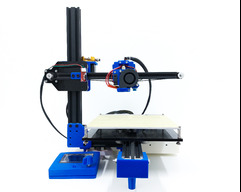

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Scotty Orr

Views

11631

Build Author

Scotty Orr

Views

11631

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

First Ever Build

This is my first attempt at building my own 3d printer.

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

Nicademus

Views

9543

Build Author

Nicademus

Views

9543

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Connor Mckeown

Views

6396

Build Author

Connor Mckeown

Views

6396

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

BinaryConstruct

Views

10213

Build Author

BinaryConstruct

Views

10213

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

h3rb

Views

3734

Build Author

h3rb

Views

3734

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

h3rb

Views

5706

Build Author

h3rb

Views

5706

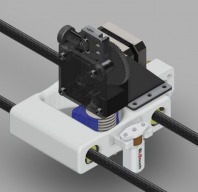

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

Rat Rig

Views

31547

Build Author

Rat Rig

Views

31547

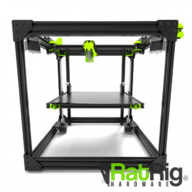

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

Build Author

JerwanDavis

Views

6069

Build Author

JerwanDavis

Views

6069

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Luke Cunningham

Views

5896

Build Author

Luke Cunningham

Views

5896

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Build Author

Bob Darrow

Views

10086

Build Author

Bob Darrow

Views

10086

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

Mark Carew

Views

27103

Build Author

Mark Carew

Views

27103

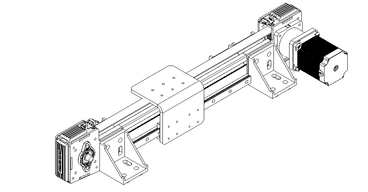

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

deltajegga

Views

9885

Build Author

deltajegga

Views

9885

THE delta

probably as big as you'd want it...

GhettoPrinter

Dirt cheap build.

Vulcan Pro V1

A posi-drive leveling printer in 300x300x380mm format that easily breaks down for suitcase size shipping.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

Build Author

Keith Davis

Views

4058

Build Author

Keith Davis

Views

4058

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

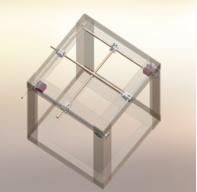

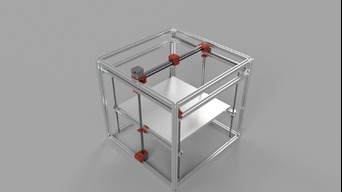

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

18x36x16 Inch 3D Printer - Work in progress

Tough 3D Printer using OpenBuilds Parts!

Mini Additive Manufacturing Printer by Chris Scholl

Mini Additive Manufacturing Printer by Chris Scholl

Build Author

shanehooper

Views

15845

Build Author

shanehooper

Views

15845

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Leboeuf

Views

4989

Build Author

Leboeuf

Views

4989

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

3D Printer 051

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

Build Author

Genetoys

Views

3312

Build Author

Genetoys

Views

3312

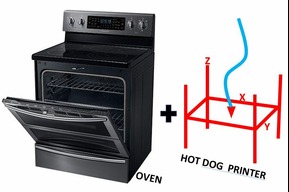

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

ME-Mini 3D Printer

Prusa mini inspired 3d printer

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Build Author

Ahmed Ibrahim

Views

9867

Build Author

Ahmed Ibrahim

Views

9867

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

Elias Ramburger

Views

6041

Build Author

Elias Ramburger

Views

6041

600 volume 3D-Printer "ABEA"

Hello. I build this 600 by 600 printer and hope to share it. I plan to sell custom builds with my website in the middle of this yeahr while making all parts accesibble online for replacements and own builds. My plan was to build a better and more accessible big volume 3d-printer as cheap as possible. I got some inspiration of the ender creality 3, the crazy-Print xyz 300 and the veho 600 tronxy which was simply not relaible and satisfying overal.

Build Author

David E. Flores E.

Views

3337

Build Author

David E. Flores E.

Views

3337

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...