Build List

-

Active Filters:

tr

Build Author

Troy Joachim

Views

18541

Build Author

Troy Joachim

Views

18541

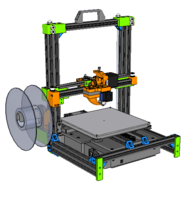

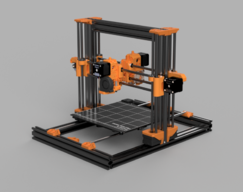

Prusa i3 Bear IDEX

Remix of the Prusa i3 Bear with added IDEX

Build Author

MechEng

Views

15944

Build Author

MechEng

Views

15944

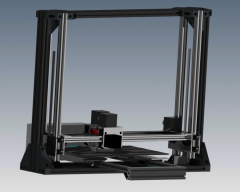

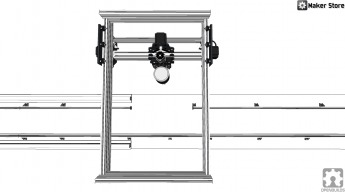

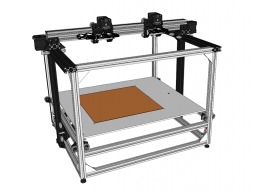

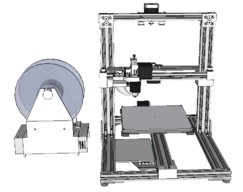

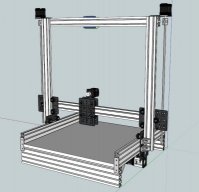

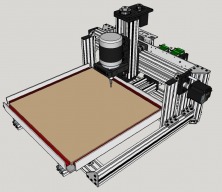

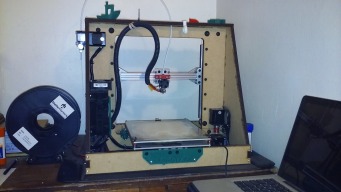

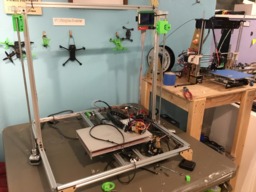

Generic Rigid 3D Printer (Currently on 1st Revision!)

Rigid 3d printer with more than enough room for dual extruders. Easily expandable platform.

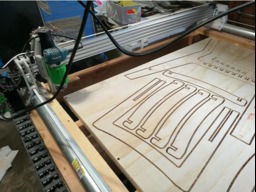

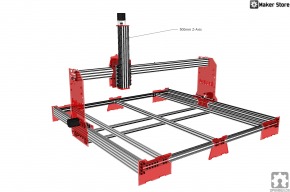

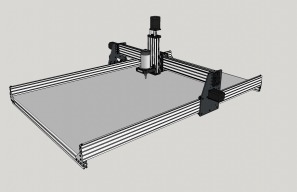

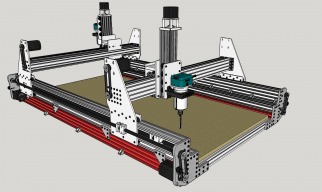

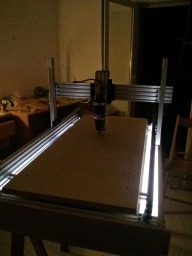

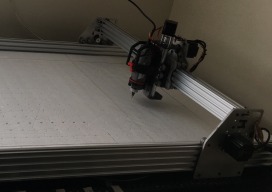

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Build Author

Jovian

Views

30277

Build Author

Jovian

Views

30277

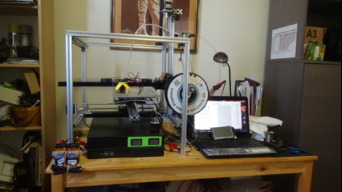

Proteus

Proteus is the Greek God of change. Besides the numerous aspect of 3D printing that this could relate to this machine like the god can change. The Build allows for an interchanging head that will allow different functionality to be quickly and easily adapted. So you could print clay, silicon, plastic, cut with a laser cutter or even attach a rotary tool

Build Author

Mark Carew

Views

109299

Build Author

Mark Carew

Views

109299

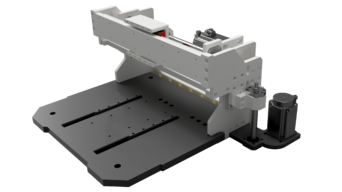

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

OpenBuilds

Views

29830

Build Author

OpenBuilds

Views

29830

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

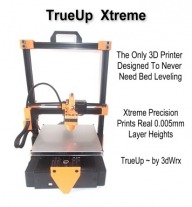

TrueUp Kit Version

A Cartesian printer using bushings for the Z axis instead of wheels or linear bearings. The design also synchronizes two Z axis screws with a timing belt for a level lift. The ratio of the drive pulley and Z axis pulleys produce .005 lift per full step on a 200 step motor, eliminating layer resolution "drift" caused by microstepping.

Build Author

Christer Langley

Views

9485

Build Author

Christer Langley

Views

9485

CNC-Solutions Build

My first Build with V-slot

Build Author

Pol Feliu

Views

9292

Build Author

Pol Feliu

Views

9292

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

Zootalaws

Views

6494

Build Author

Zootalaws

Views

6494

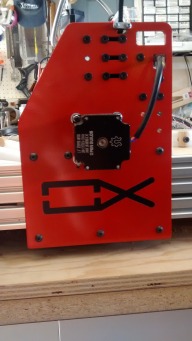

OXENlarged

This is a 1500 x 1500 Ox build

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

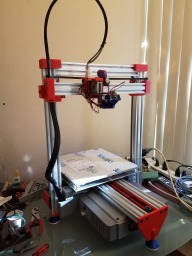

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

Build Author

adamcooks

Views

43426

Build Author

adamcooks

Views

43426

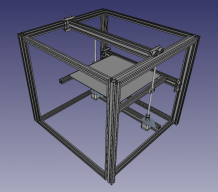

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Build Author

Steve hope

Views

19256

Build Author

Steve hope

Views

19256

8x4 CNC build

Routy cnc upgrade.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

Kyo

Views

10635

Build Author

Kyo

Views

10635

Fina

This is Fina; My Lautr3k inspired build.

Cancelled - Modified OX CNC for Mitre Cutting (Picture Framing)

Creating a CNC mitre (45°) cutter, for picture frame cutting. Starting with an OX, but inverting various parts and adding a material table, with a stepper-controlled measuring guide.

Build Author

MikieLikesIt

Views

8284

Build Author

MikieLikesIt

Views

8284

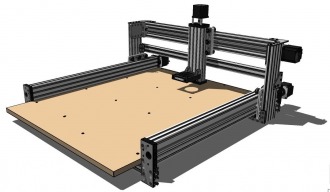

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

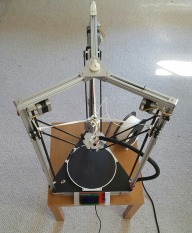

Delta Bot: Improved DIY 3D Printer

Build the efficient and reliable all metal structure 3D Printer. Improved significantly with new concepts for printers. Great quality and up to 400 mm/s print speed (very fast). Built with heated bed, hybrid bowden suspended extruder, and counterweight (tested printing 21 hours straight with no motors hot). Optional smart controller for computerless printing. Print any kind of thermoplastic.

Build Author

Peter Oakes

Views

44391

Build Author

Peter Oakes

Views

44391

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

Fabio Bertuzz

Views

4278

Build Author

Fabio Bertuzz

Views

4278

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

Build Author

zann68

Views

9382

Build Author

zann68

Views

9382

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6205

Build Author

Gary Bonard

Views

6205

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

David Arroyo

Views

14735

Build Author

David Arroyo

Views

14735

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Build Author

Nwrgordon

Views

15937

Build Author

Nwrgordon

Views

15937

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

Build Author

Cbrown330

Views

5425

Build Author

Cbrown330

Views

5425

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Build Author

Paruk

Views

23217

Build Author

Paruk

Views

23217

Buffal-O-Tron

A 3D Scanning Station

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

My First CNC Machine

This will be a step by step record charting my successes and failures in my voyage of discovery while building a CNC router. Please excuse my English-English which may lose something in translation to American-English. I would be grateful for any advice during the build

Build Author

eddyg

Views

5033

Build Author

eddyg

Views

5033

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Build Author

Metalguru

Views

14782

Build Author

Metalguru

Views

14782

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

William Niedermeyer

Views

19722

Build Author

William Niedermeyer

Views

19722

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

Build Author

mytechno3d

Views

6516

Build Author

mytechno3d

Views

6516

DSLR ( video ) motorized slider

In order to make some nice traveling video you need a slider .

Build Author

Dave420

Views

14577

Build Author

Dave420

Views

14577

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Build Author

Jose A. Molina

Views

7057

Build Author

Jose A. Molina

Views

7057

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Krishnakumar

Views

8818

Build Author

Krishnakumar

Views

8818

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

crystaldragon141

Views

6604

Build Author

crystaldragon141

Views

6604

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

dodgenet

Views

6626

Build Author

dodgenet

Views

6626

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

mikev

Views

8626

Build Author

mikev

Views

8626

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Thair.nl

Views

3842

Build Author

Thair.nl

Views

3842

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Wifi'not

A simple made hideaway for ugly electronics

Build Author

Tom Dirriwachter

Views

7407

Build Author

Tom Dirriwachter

Views

7407

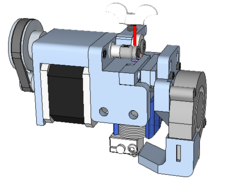

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

Dmknerr

Views

5247

Build Author

Dmknerr

Views

5247

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Chetan PM

Views

3850

Build Author

Chetan PM

Views

3850

Composer

Gantry style rigid build

Double trolley X and Z belt training

Total belt drive GT2

Build Author

J-Wahl Dezign

Views

9171

Build Author

J-Wahl Dezign

Views

9171

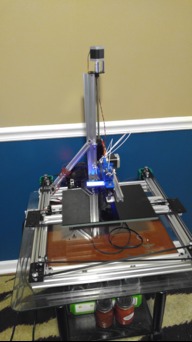

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

3D Meister

Views

5573

Build Author

3D Meister

Views

5573

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

Robert E. Nee

Views

17632

Build Author

Robert E. Nee

Views

17632

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Build Author

Peter Van Der Walt

Views

7503

Build Author

Peter Van Der Walt

Views

7503

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

evgeny156

Views

7368

Build Author

evgeny156

Views

7368

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Fabio Orsi

Views

6973

Build Author

Fabio Orsi

Views

6973

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

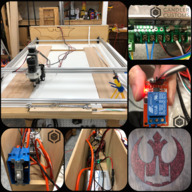

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

megashub

Views

24396

Build Author

megashub

Views

24396

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Build Author

Scotty Orr

Views

11754

Build Author

Scotty Orr

Views

11754

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

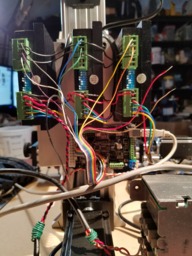

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Build Author

Jason Harding

Views

4119

Build Author

Jason Harding

Views

4119

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

TrueUp Bold

A beefed up modification of the TrueUp Kit project

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

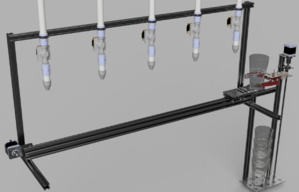

Automatic Sprayer

Automatic spray machine.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

Build Author

Anthony Castelluci

Views

3256

Build Author

Anthony Castelluci

Views

3256

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

TimVukman

Views

4335

Build Author

TimVukman

Views

4335

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

patdee

Views

5149

Build Author

patdee

Views

5149

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

Lindsey Lewis

Views

8266

Build Author

Lindsey Lewis

Views

8266

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

ZacharyB

Views

5790

Build Author

ZacharyB

Views

5790

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Dave Pyatt

Views

4553

Build Author

Dave Pyatt

Views

4553

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2851

Build Author

Terone Burgenheim

Views

2851

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6495

Build Author

Terone Burgenheim

Views

6495

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8507

Build Author

Carl van Heezik

Views

8507

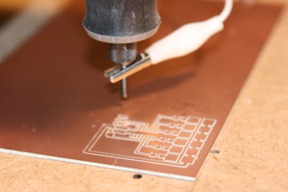

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

cory stafford

Views

4803

Build Author

cory stafford

Views

4803

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

MidnightQuads

Views

3937

Build Author

MidnightQuads

Views

3937

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12435

Build Author

GDanger117

Views

12435

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

9066

Build Author

Lindsey Lewis

Views

9066

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5482

Build Author

Keith Davis

Views

5482

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3801

Build Author

George Motichka

Views

3801

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

6142

Build Author

RJ_Make

Views

6142

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5604

Build Author

CandlerCustoms

Views

5604

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5845

Build Author

Sam Price

Views

5845

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Camvec

Views

6313

Build Author

Camvec

Views

6313

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

Rodrigo Gonzalez

Views

3674

Build Author

Rodrigo Gonzalez

Views

3674

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Bill325

Views

2379

Build Author

Bill325

Views

2379

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

OffAxis

Views

7801

Build Author

OffAxis

Views

7801

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Nicademus

Views

9629

Build Author

Nicademus

Views

9629

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

5160

Build Author

Rob Withoff

Views

5160

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

TurfnSurf

Views

6248

Build Author

TurfnSurf

Views

6248

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

JAC_101

Views

6111

Build Author

JAC_101

Views

6111

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).