Build List

-

Active Filters:

nc

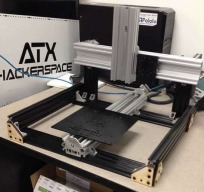

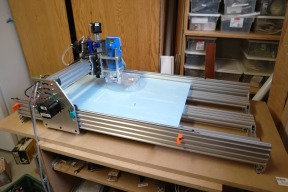

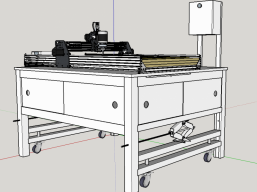

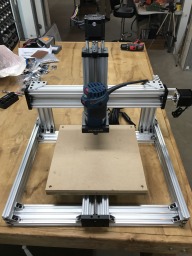

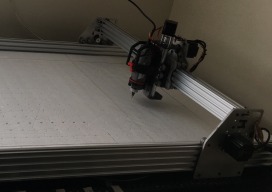

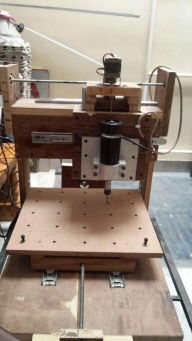

My CnC Router, custom DIY not open builds parts

Most of the way through the build, hopefully soon I will have it running

Build Author

Peter Oakes

Views

44264

Build Author

Peter Oakes

Views

44264

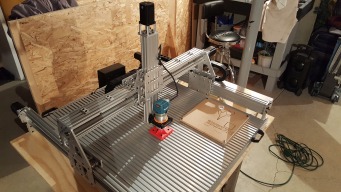

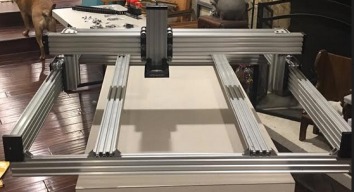

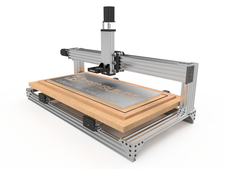

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

C beam cnc modified

C beam cnc modified

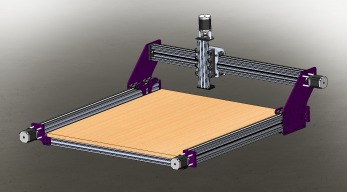

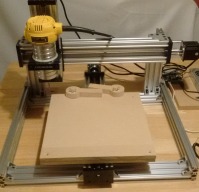

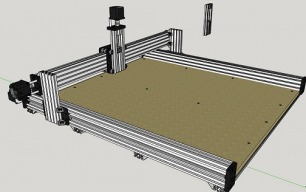

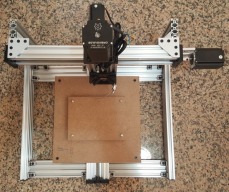

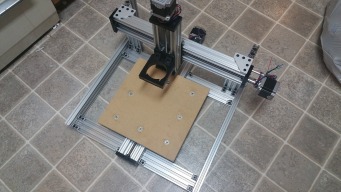

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

C-Beam Machine Bundle

Short description of my assembly and use of the C-Beam bundle from the Open Builds Part Store.

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

Build Author

zann68

Views

9292

Build Author

zann68

Views

9292

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6175

Build Author

Gary Bonard

Views

6175

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Ooznest OX CNC Build

Ooznest OX CNC build

Build Author

David Arroyo

Views

14648

Build Author

David Arroyo

Views

14648

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Build Author

Julius

Views

8201

Build Author

Julius

Views

8201

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

My Second CNC

In short...this was a fun project.

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

Colin Russon

Views

9418

Build Author

Colin Russon

Views

9418

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

evil2002usna

Views

11560

Build Author

evil2002usna

Views

11560

Evil Ox

Cheap Ballscrew Ox CNC Router.

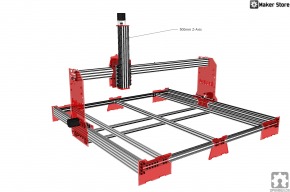

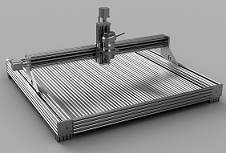

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Builder+Bob

Views

3752

Build Author

Builder+Bob

Views

3752

Portable C-Beam

C-Beam Plate maker for My OX!

Expanded Routy using 290 build instructions

Using the Routy290 build and an awful lot of help from puntoMX, this machine has been expanded in the X and Y axis. My first build, I'm learning a lot about all of this. I've had to disassemble parts of this thing many times due to forgetfulness, but that's ok. Also, I've forgotten to take constant pictures throughout the build.

Build Author

Charles Roseberry

Views

5056

Build Author

Charles Roseberry

Views

5056

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

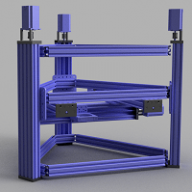

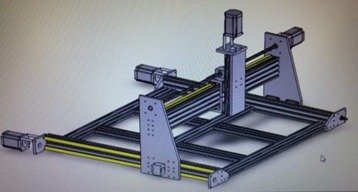

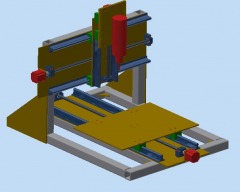

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Build Author

Rob Taylor

Views

20189

Build Author

Rob Taylor

Views

20189

Portable Diode Laser Cutter

Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel.

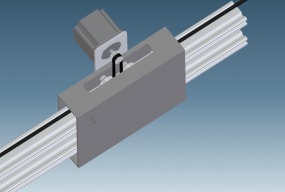

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

Large OX

A larger version of the OX.

Build Author

Matt Nelson

Views

12283

Build Author

Matt Nelson

Views

12283

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

Anthony Bolgar

Views

12030

Build Author

Anthony Bolgar

Views

12030

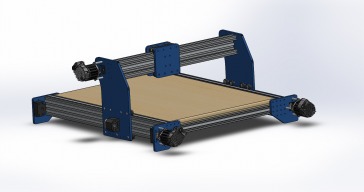

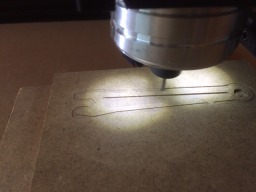

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

Build Author

UltiBots

Views

10563

Build Author

UltiBots

Views

10563

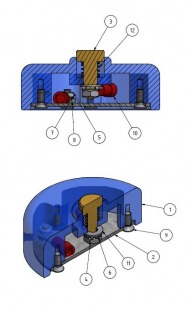

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

CNC

This is my CNC build. My goal is to have fun and learn some new things.

Build Author

Rwetzler

Views

9367

Build Author

Rwetzler

Views

9367

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Schematix OX metal build

OX metal build from an noob

Build Author

Krishnakumar

Views

8730

Build Author

Krishnakumar

Views

8730

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

AK-Creation

Views

14935

Build Author

AK-Creation

Views

14935

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

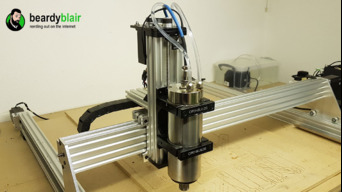

Build Author

beardyblair

Views

25297

Build Author

beardyblair

Views

25297

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Build Author

Edgar Robles

Views

4093

Build Author

Edgar Robles

Views

4093

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

C-Machine

MY experience as a first time introduction to the CNC world!

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Build Author

Ken376

Views

3744

Build Author

Ken376

Views

3744

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

mikev

Views

8577

Build Author

mikev

Views

8577

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

signzonepr

Views

13026

Build Author

signzonepr

Views

13026

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

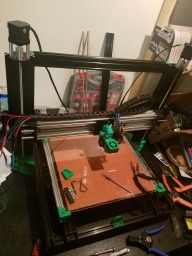

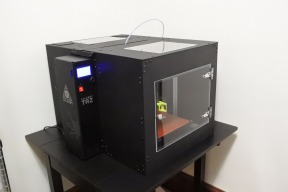

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Build Author

Linkreincarnate

Views

3131

Build Author

Linkreincarnate

Views

3131

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Greg Lampman

Views

9220

Build Author

Greg Lampman

Views

9220

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

A work in progress

One of my first projects might be cutting proper plates.

Build Author

Robert Huxford

Views

3979

Build Author

Robert Huxford

Views

3979

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7497

Build Author

Matt Barile

Views

7497

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

Rich Bowen

Views

3840

Build Author

Rich Bowen

Views

3840

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

Build Author

Jonathon Duerig

Views

7200

Build Author

Jonathon Duerig

Views

7200

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

Tomas F Uribe

Views

5338

Build Author

Tomas F Uribe

Views

5338

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Huub65

Views

9284

Build Author

Huub65

Views

9284

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

Karan Singh Sisodia

Views

6302

Build Author

Karan Singh Sisodia

Views

6302

My Home made CNC

Home Made CNC Router from Scrape

Build Author

islahcnc

Views

4450

Build Author

islahcnc

Views

4450

islahcnc&design

I will post soon some more details.

Build Author

JerryD

Views

5334

Build Author

JerryD

Views

5334

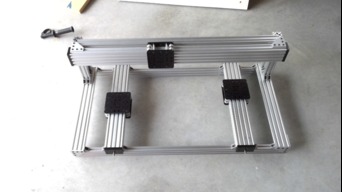

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4082

Build Author

Jason Harding

Views

4082

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Build Author

Jeremiah Guinn

Views

5837

Build Author

Jeremiah Guinn

Views

5837

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

Build Author

Tucstrlly

Views

9071

Build Author

Tucstrlly

Views

9071

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Build Author

Kyo

Views

10075

Build Author

Kyo

Views

10075

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.