Build List

-

Active Filters:

nc

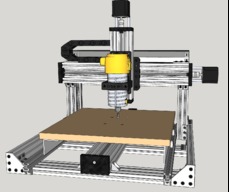

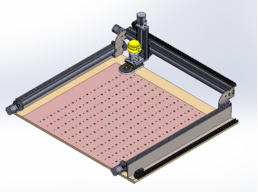

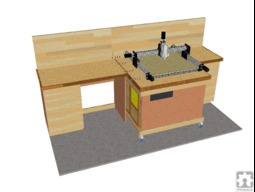

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Ancient Roland Table top Mill

The parts are now very reasonable.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Lindsey Lewis

Views

8164

Build Author

Lindsey Lewis

Views

8164

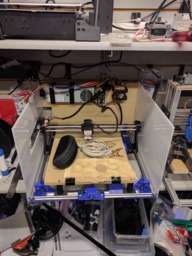

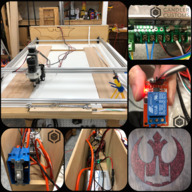

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

pedrofernandez

Views

12170

Build Author

pedrofernandez

Views

12170

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Dave Pyatt

Views

4510

Build Author

Dave Pyatt

Views

4510

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2829

Build Author

Terone Burgenheim

Views

2829

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

cory stafford

Views

4777

Build Author

cory stafford

Views

4777

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

GDanger117

Views

12333

Build Author

GDanger117

Views

12333

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

CandlerCustoms

Views

5556

Build Author

CandlerCustoms

Views

5556

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Bill325

Views

2338

Build Author

Bill325

Views

2338

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

OffAxis

Views

7726

Build Author

OffAxis

Views

7726

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Nicademus

Views

9558

Build Author

Nicademus

Views

9558

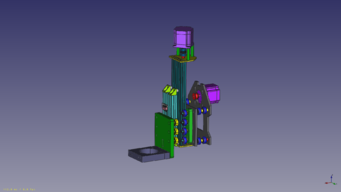

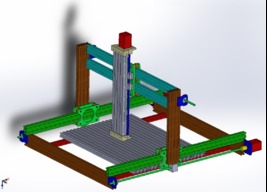

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

TurfnSurf

Views

6212

Build Author

TurfnSurf

Views

6212

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

JAC_101

Views

6073

Build Author

JAC_101

Views

6073

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

MattR

Views

20291

Build Author

MattR

Views

20291

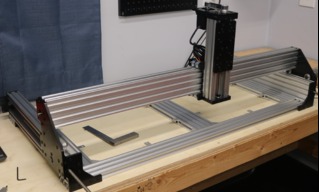

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Denis Lapratte

Views

4557

Build Author

Denis Lapratte

Views

4557

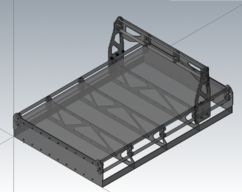

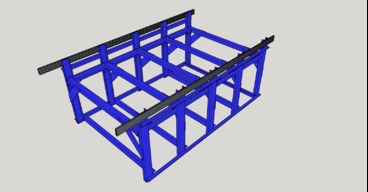

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

bpatterson42

Views

3573

Build Author

bpatterson42

Views

3573

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

TurfnSurf

Views

7136

Build Author

TurfnSurf

Views

7136

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5688

Build Author

spark2

Views

5688

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Sprags

Views

2737

Build Author

Sprags

Views

2737

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

jz321

Views

4559

Build Author

jz321

Views

4559

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

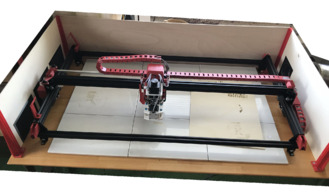

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Big CNC plasma cutter

more later

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Bucky Wootmaster

Views

2994

Build Author

Bucky Wootmaster

Views

2994

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Build Author

h3rb

Views

3740

Build Author

h3rb

Views

3740

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

pedrofernandez

Views

7921

Build Author

pedrofernandez

Views

7921

ACRO 20x20

The Acro Laser Machine Build

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Build Author

Limine3D

Views

4547

Build Author

Limine3D

Views

4547

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Something a Tad different

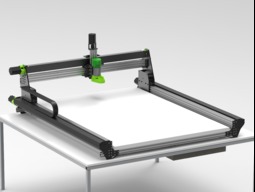

Future CNC router kit design

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

Kevr102

Views

5827

Build Author

Kevr102

Views

5827

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Hussein Dermay

Views

6499

Build Author

Hussein Dermay

Views

6499

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Build Author

Brandon Satterfield

Views

7709

Build Author

Brandon Satterfield

Views

7709

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

jpjoshua

Views

13390

Build Author

jpjoshua

Views

13390

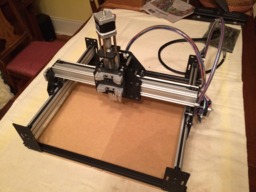

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

Mark Carew

Views

33809

Build Author

Mark Carew

Views

33809

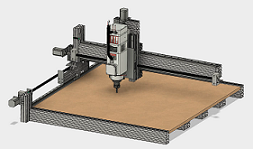

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Mark Carew

Views

77674

Build Author

Mark Carew

Views

77674

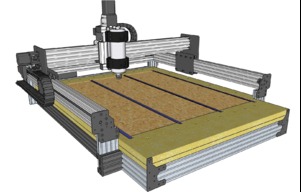

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

28092

Build Author

Mark Carew

Views

28092

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

Mark Carew

Views

25298

Build Author

Mark Carew

Views

25298

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Andreas Bockert

Views

11989

Build Author

Andreas Bockert

Views

11989

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

Hilleke

Views

7850

Build Author

Hilleke

Views

7850

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Build Author

mytechno3d

Views

15487

Build Author

mytechno3d

Views

15487

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Build Author

Jones

Views

3993

Build Author

Jones

Views

3993

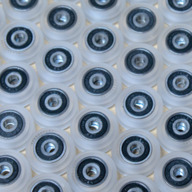

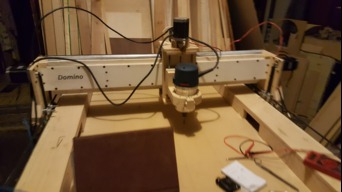

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

Rob Taylor

Views

10940

Build Author

Rob Taylor

Views

10940

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

C-CNC

Views

16180

Build Author

C-CNC

Views

16180

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Mark Carew

Views

6180

Build Author

Mark Carew

Views

6180

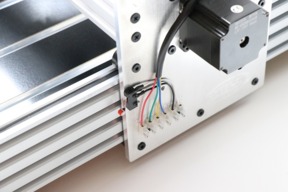

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

27177

Build Author

Mark Carew

Views

27177

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Kyo

Views

45690

Build Author

Kyo

Views

45690

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Build Author

Mark Carew

Views

8974

Build Author

Mark Carew

Views

8974

OpenBuilds PowerCase

A simple to assemble, super clean and safe PSU case solution that fits into the OpenBuilds wire management ecosystem

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

RobFromLDMS

Views

5246

Build Author

RobFromLDMS

Views

5246

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

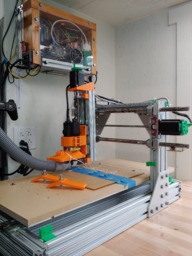

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

joetemus

Views

6834

Build Author

joetemus

Views

6834

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

Craig Hollabaugh

Views

4891

Build Author

Craig Hollabaugh

Views

4891

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Vin1027

Views

7336

Build Author

Vin1027

Views

7336

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Bikes and Beer

Views

4857

Build Author

Bikes and Beer

Views

4857

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

Build Author

Troy Proffitt

Views

29006

Build Author

Troy Proffitt

Views

29006

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Spark Concepts

Views

16667

Build Author

Spark Concepts

Views

16667

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Build Author

Christian James

Views

9945

Build Author

Christian James

Views

9945

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Doug Rowley

Views

4340

Build Author

Doug Rowley

Views

4340

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

patnap71

Views

6895

Build Author

patnap71

Views

6895

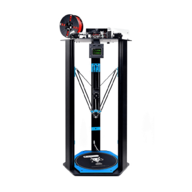

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

Build Author

msdosfx

Views

6157

Build Author

msdosfx

Views

6157

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

OoozNest WorkBee

A Journey on the WorkBee Build...

Build Author

Stan Howe

Views

3340

Build Author

Stan Howe

Views

3340

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

My build

I am satisfied with my build and next one will be even better.

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

Cortellini

Views

4510

Build Author

Cortellini

Views

4510

The FEEDBACK FRACTAL Build

The Feedback Fractal Project (Project) - building "A Monument For Our Time." As its intent is to build a monumental sculpture, the Project will produce an object d'art. Yet, once begun, the Project has evolved a life and character of its own. I continue to follow the thread woven by the materials, the processes, and the people that come to it and in the end the work will not only be a faithful rendition of an image and a concept, it will also be a tapestry of the story of its making.

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

Build Author

KronBjorn

Views

4474

Build Author

KronBjorn

Views

4474

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

James Evanko

Views

7302

Build Author

James Evanko

Views

7302

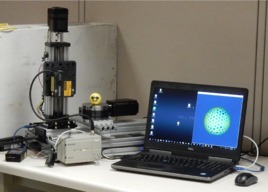

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

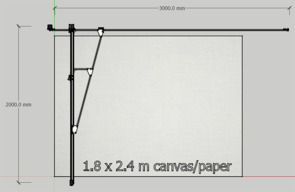

SB Plotter

Large floor or wall mounted plotter design.

CNC Router Machine

CNC Router with working area 550*550*200

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.