Build List

-

Active Filters:

be

Build Author

Carl Siren

Views

7558

Build Author

Carl Siren

Views

7558

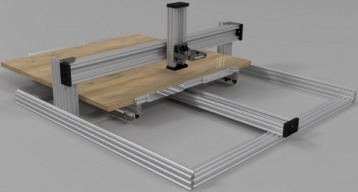

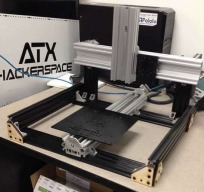

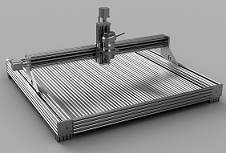

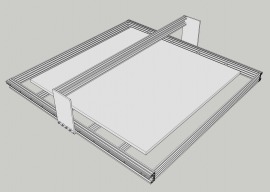

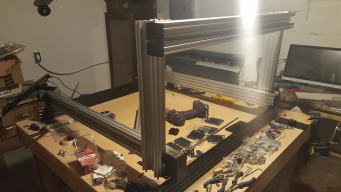

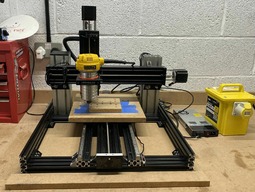

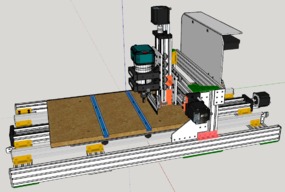

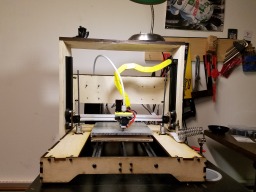

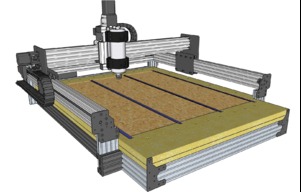

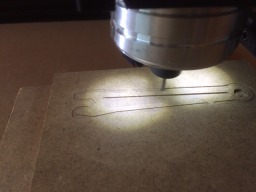

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

KillerBee 1515 customized

Killerbee 1515 with modifications.

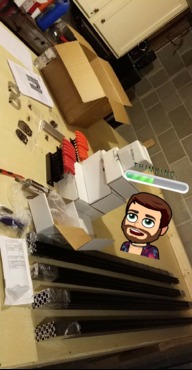

C-BEAM 1K

The new C-Beam kit expanded to 1000mm . extra support built in for the extents of the travel.

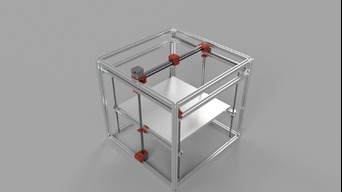

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Build Author

Josh Mascote

Views

7339

Build Author

Josh Mascote

Views

7339

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

C-Beam Plate Machine

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

Corey Corbin

Views

7303

Build Author

Corey Corbin

Views

7303

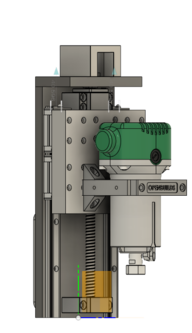

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Build Author

Vin1027

Views

7246

Build Author

Vin1027

Views

7246

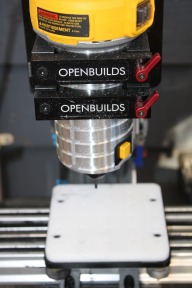

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Shaun Weitzel

Views

7218

Build Author

Shaun Weitzel

Views

7218

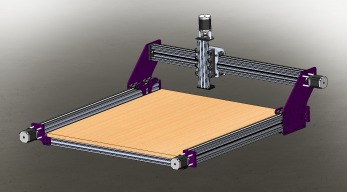

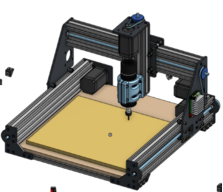

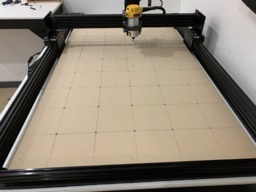

OpenBuilds Lead 1515

First build of a Lead 1515!

Build Author

ChrisViral

Views

7065

Build Author

ChrisViral

Views

7065

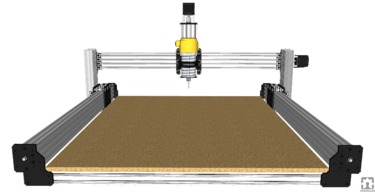

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

Sonny Lowe

Views

6919

Build Author

Sonny Lowe

Views

6919

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

andrizzle

Views

6874

Build Author

andrizzle

Views

6874

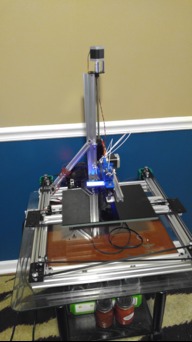

Printer1

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

Build Author

Jose A. Molina

Views

6858

Build Author

Jose A. Molina

Views

6858

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

Stokrotka74

Views

6816

Build Author

Stokrotka74

Views

6816

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Build Author

patnap71

Views

6792

Build Author

patnap71

Views

6792

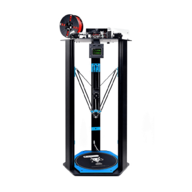

MEGADELTA, TLM CLONE with 500MM bed

All metal frame 500mm bed Delta 3D printer

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

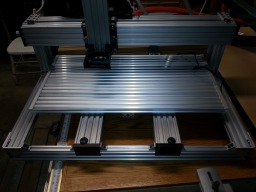

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

txcomp

Views

6747

Build Author

txcomp

Views

6747

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

Vunnie

Views

6730

Build Author

Vunnie

Views

6730

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

OpenBuilds

Views

6594

Build Author

OpenBuilds

Views

6594

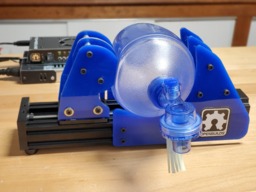

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Build Author

Ariel Yahni

Views

6483

Build Author

Ariel Yahni

Views

6483

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

Build Author

Kyo

Views

6464

Build Author

Kyo

Views

6464

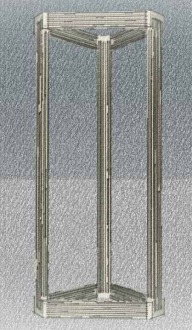

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

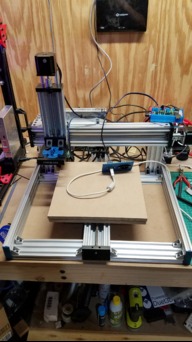

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Build Author

DIY3DTech.com

Views

6441

Build Author

DIY3DTech.com

Views

6441

3D Printer Leveler Made with Maker Rail

Leveling Platform / Stand 3D Printers

Build Author

Hussein Dermay

Views

6398

Build Author

Hussein Dermay

Views

6398

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Terone Burgenheim

Views

6348

Build Author

Terone Burgenheim

Views

6348

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

Camvec

Views

6189

Build Author

Camvec

Views

6189

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

inhan

Views

6148

Build Author

inhan

Views

6148

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Build Author

msdosfx

Views

6088

Build Author

msdosfx

Views

6088

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

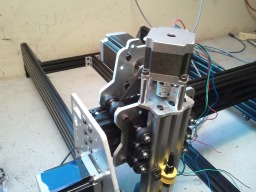

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

Build Author

DaveStewart

Views

6011

Build Author

DaveStewart

Views

6011

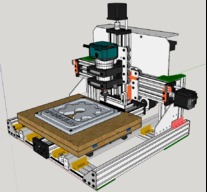

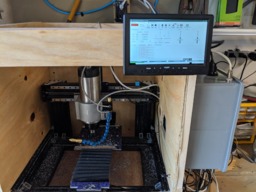

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Build Author

JerwanDavis

Views

6011

Build Author

JerwanDavis

Views

6011

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

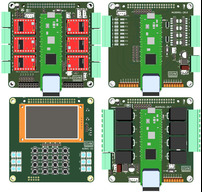

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

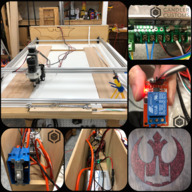

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

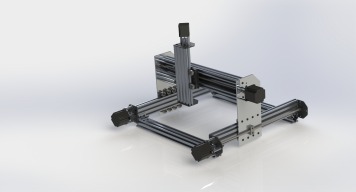

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

KerryH's OX

My adventure in CNC routing.

Build Author

Luke Cunningham

Views

5839

Build Author

Luke Cunningham

Views

5839

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Jeremiah Guinn

Views

5786

Build Author

Jeremiah Guinn

Views

5786

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

C beam cnc modified

C beam cnc modified

Build Author

jeff johnson

Views

5684

Build Author

jeff johnson

Views

5684

workbee 1510

Getting more height out of the !510

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

Build Author

spark2

Views

5605

Build Author

spark2

Views

5605

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

obmilllivebuild

Views

5563

Build Author

obmilllivebuild

Views

5563

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

C_Beam Hammerhead 5x

setup for learning 5x

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

CNC Planning

Reusing parts to build a CNC - planning stage

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

CandlerCustoms

Views

5411

Build Author

CandlerCustoms

Views

5411

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Tomas F Uribe

Views

5282

Build Author

Tomas F Uribe

Views

5282

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Murphy OX-CNC Dreamin

I am in the design phase of my CNC. I would like to thank everyone who has placed resources on the site. I am using it to the up most! I will update as I continue the design and share my progress.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

Mogens Kusk

Views

5154

Build Author

Mogens Kusk

Views

5154

Belt driven 1200mm x 700mm x170mm axis

CNC router

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

C-Beam CNC (1st cnc build!)

1st build CBeam Machine w/ raspberry pi-protoneer hat controller

C-Beam Dust Shoe

A short description of the dust shoe I made for my machine.

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

THE LINK

Views

5024

Build Author

THE LINK

Views

5024

2020 First build.

Probably cheapest DIY build youl see.

Build Author

patdee

Views

5023

Build Author

patdee

Views

5023

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

Charles Roseberry

Views

4989

Build Author

Charles Roseberry

Views

4989

C-Beam 1000mmx1000mm

C-Beam basic package doubled in size.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Build Author

Hisha

Views

4938

Build Author

Hisha

Views

4938

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Build Author

Leboeuf

Views

4885

Build Author

Leboeuf

Views

4885

Cartesian 3d printer

This is the build of a cartesian 3d printer made of an old Anet and Geeeteck, some 2020 alu profil and linear rail. Powered by a Rumba with a Nextion screen. It should be modular and accept dual Extrusion and laser engraving.

Brewery tank supports

Trying to design modular and evolutive supports for my brewery tanks.

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

Build Author

Craig Hollabaugh

Views

4788

Build Author

Craig Hollabaugh

Views

4788

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Bikes and Beer

Views

4768

Build Author

Bikes and Beer

Views

4768

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.

Build Author

James Evanko

Views

4717

Build Author

James Evanko

Views

4717

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Build Author

EvanH

Views

4635

Build Author

EvanH

Views

4635

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

C-Beam on X, Y and Z Attempting to use internal channel first go around

C-Beam build using the small C-Beam gantry plates only.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

Build Author

Limine3D

Views

4438

Build Author

Limine3D

Views

4438

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.