Build List

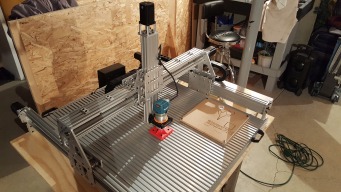

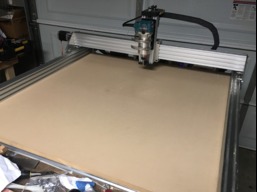

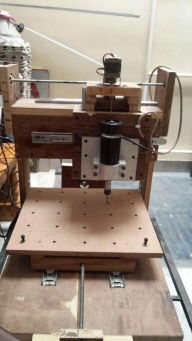

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

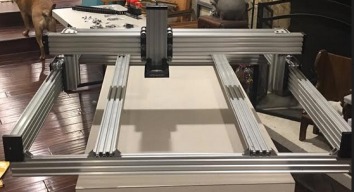

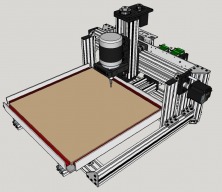

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Build Author

Builder+Bob

Views

3721

Build Author

Builder+Bob

Views

3721

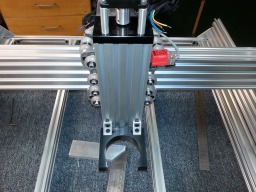

Portable C-Beam

C-Beam Plate maker for My OX!

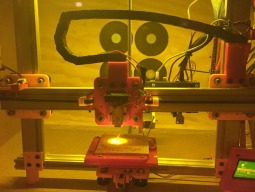

Laseroko Laser Engraver Build

After expanding a Shapeoko 2 with the rails and motors left over, make yourself a laser engraver.

Build Author

Sonny Lowe

Views

6052

Build Author

Sonny Lowe

Views

6052

MakerSL MSL-7 Laser Cut Tape Dispenser

An easy simple Tape Dispenser, spawned out of necessity, and shared for the fun of it...

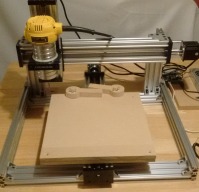

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

Large OX

A larger version of the OX.

Build Author

cbordeleau

Views

13157

Build Author

cbordeleau

Views

13157

OpenBuilds C-Beam Double Slider

This slider uses an 500mm OpenBuilds C-beam and the design is such that the effective length of the slider is slightly less then twice the length of the C-Beam. It can be used both motorized or not.

Build Author

Matt Nelson

Views

12226

Build Author

Matt Nelson

Views

12226

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

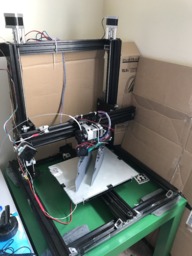

CNC

This is my CNC build. My goal is to have fun and learn some new things.

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Build Author

Metalguru

Views

14579

Build Author

Metalguru

Views

14579

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

griso

Views

9212

Build Author

griso

Views

9212

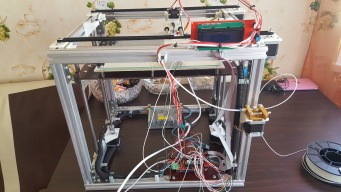

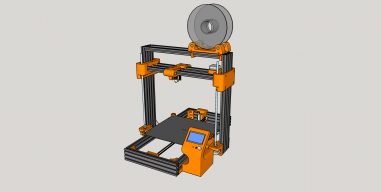

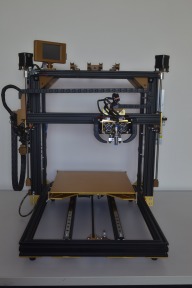

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

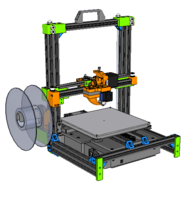

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Build Author

mytechno3d

Views

6447

Build Author

mytechno3d

Views

6447

DSLR ( video ) motorized slider

In order to make some nice traveling video you need a slider .

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Custom Ox

Custom black and red Big Ox

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

Build Author

Krishnakumar

Views

8666

Build Author

Krishnakumar

Views

8666

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

AK-Creation

Views

14859

Build Author

AK-Creation

Views

14859

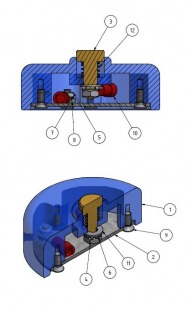

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

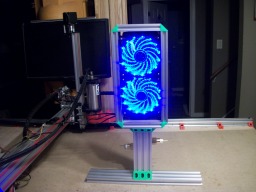

Spindle cooling setup

Cooling system for water cooled spindle.

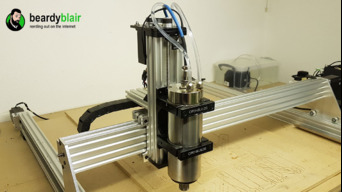

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

beardyblair

Views

25240

Build Author

beardyblair

Views

25240

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

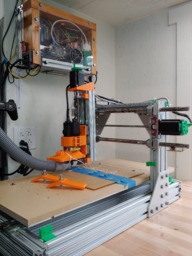

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

Build Author

Edgar Robles

Views

4070

Build Author

Edgar Robles

Views

4070

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

C-Machine

MY experience as a first time introduction to the CNC world!

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

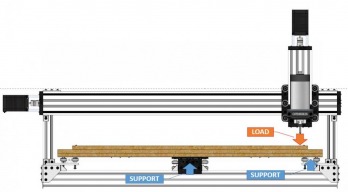

Linear Rail for Dobot Magician

This is a simpel build of a Linear rail for the Dobot Magician.

Build Author

JP Warnke

Views

12763

Build Author

JP Warnke

Views

12763

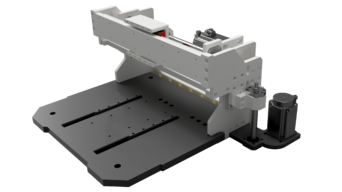

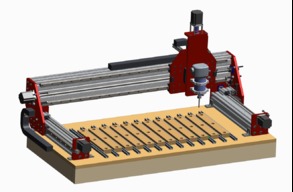

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

mikev

Views

8544

Build Author

mikev

Views

8544

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Build Author

signzonepr

Views

12992

Build Author

signzonepr

Views

12992

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

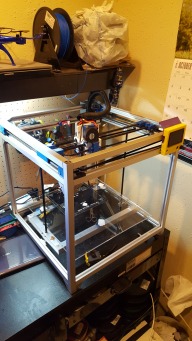

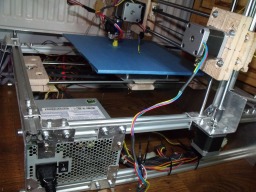

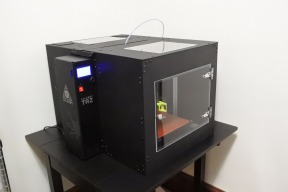

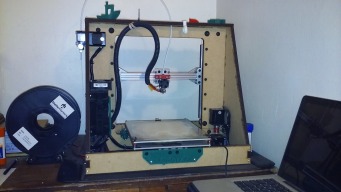

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Wifi'not

A simple made hideaway for ugly electronics

Build Author

Makerparts

Views

7658

Build Author

Makerparts

Views

7658

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Tom Dirriwachter

Views

7323

Build Author

Tom Dirriwachter

Views

7323

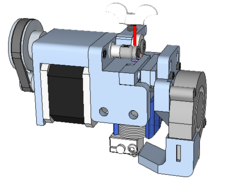

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

Chetan PM

Views

3776

Build Author

Chetan PM

Views

3776

Composer

Gantry style rigid build

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

3D Meister

Views

5453

Build Author

3D Meister

Views

5453

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

Build Author

Peter Van Der Walt

Views

7366

Build Author

Peter Van Der Walt

Views

7366

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

recoush

Views

9190

Build Author

recoush

Views

9190

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7167

Build Author

Jonathon Duerig

Views

7167

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

FLSUN Kossel 3D printer

A brief write up of the making of the FLSUN Delta Kit. This kit is based on an open source design. I had a need for a 3D printer without the desire to dive into another project, so a kit was the obvious way to go. I already have a delta printer in the works and so this is more of a stop gap in the interim.

Build Author

Tomas F Uribe

Views

5305

Build Author

Tomas F Uribe

Views

5305

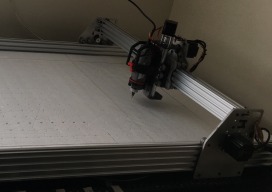

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

Huub65

Views

9198

Build Author

Huub65

Views

9198

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Karan Singh Sisodia

Views

6255

Build Author

Karan Singh Sisodia

Views

6255

My Home made CNC

Home Made CNC Router from Scrape

Build Author

islahcnc

Views

4423

Build Author

islahcnc

Views

4423

islahcnc&design

I will post soon some more details.

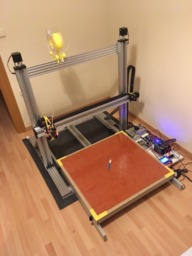

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Build Author

Scotty Orr

Views

11548

Build Author

Scotty Orr

Views

11548

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

First Ever Build

This is my first attempt at building my own 3d printer.

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

TrueUp Bold

A beefed up modification of the TrueUp Kit project

Automatic Sprayer

Automatic spray machine.

My MiniMill is just the start

This is my first build and I've been waiting to do this for a very long time.

Build Author

SecretSpy711

Views

22439

Build Author

SecretSpy711

Views

22439

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

Anthony Castelluci

Views

3205

Build Author

Anthony Castelluci

Views

3205

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

New 2 watt laser platform

Acro based 2 watt laser platform

Build Author

Kyo

Views

10017

Build Author

Kyo

Views

10017

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Lindsey Lewis

Views

8096

Build Author

Lindsey Lewis

Views

8096

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

pedrofernandez

Views

12132

Build Author

pedrofernandez

Views

12132

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

ZacharyB

Views

5723

Build Author

ZacharyB

Views

5723

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Terone Burgenheim

Views

2801

Build Author

Terone Burgenheim

Views

2801

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6400

Build Author

Terone Burgenheim

Views

6400

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

GDanger117

Views

12267

Build Author

GDanger117

Views

12267

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

8956

Build Author

Lindsey Lewis

Views

8956

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5399

Build Author

Keith Davis

Views

5399

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3749

Build Author

George Motichka

Views

3749

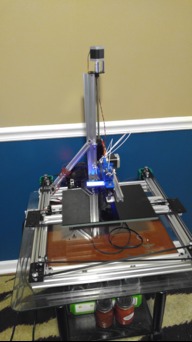

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

5982

Build Author

RJ_Make

Views

5982

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5466

Build Author

CandlerCustoms

Views

5466

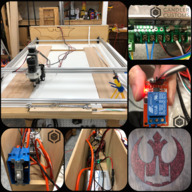

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

JAC_101

Views

6029

Build Author

JAC_101

Views

6029

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

MattR

Views

19971

Build Author

MattR

Views

19971

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

jz321

Views

4513

Build Author

jz321

Views

4513

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.