CNC ROUTER BUILDS

Build Author

Mark Carew

Views

1209463

Build Author

Mark Carew

Views

1209463

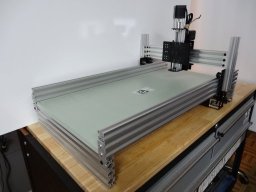

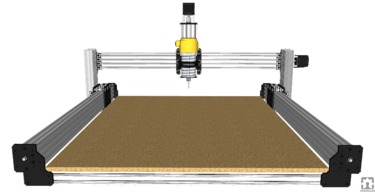

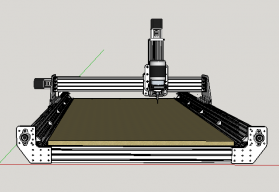

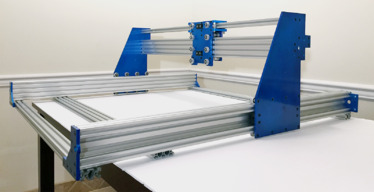

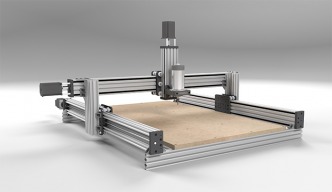

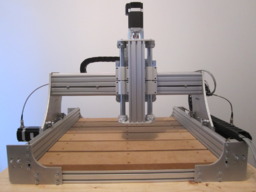

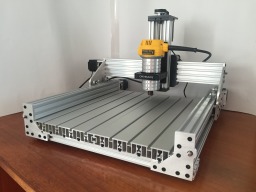

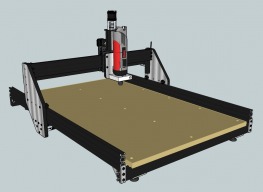

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

Kyo

Views

145156

Build Author

Kyo

Views

145156

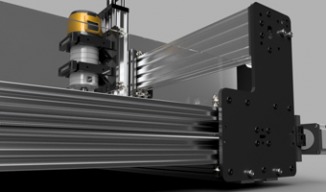

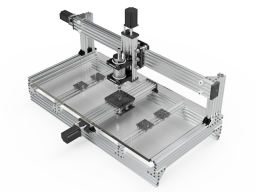

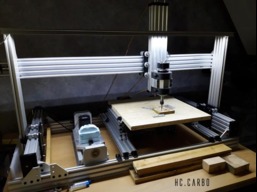

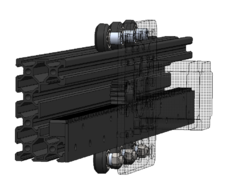

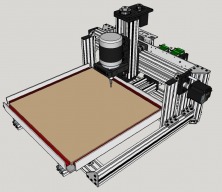

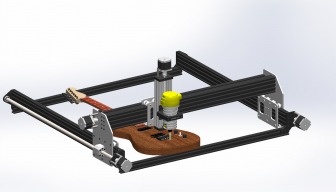

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Build Author

Schematix

Views

158139

Build Author

Schematix

Views

158139

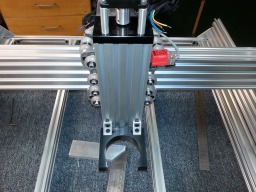

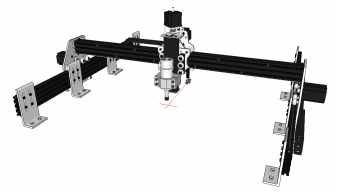

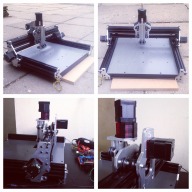

OX-Metal CNC Router Mill

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

Build Author

sgspenceley

Views

206701

Build Author

sgspenceley

Views

206701

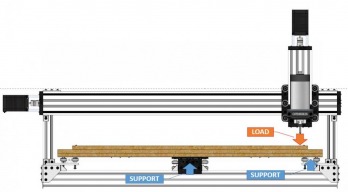

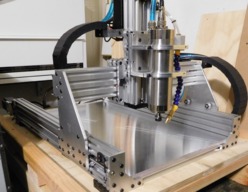

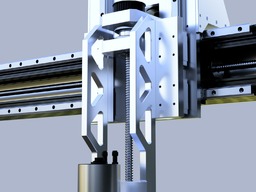

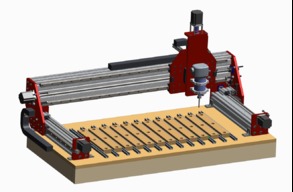

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

Build Author

Michael.M

Views

68904

Build Author

Michael.M

Views

68904

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

C-BEAM-GTC

Building a larger C-BEAM CNC Machine with no previous experience.

OX AI

This will be an Aluminum OX build. Plates and all design credit goes to Mark from open builds. I may add my own touches but mainly this is to see how Aluminum plates perform

Build Author

T4Concepts

Views

81170

Build Author

T4Concepts

Views

81170

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

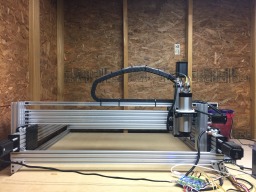

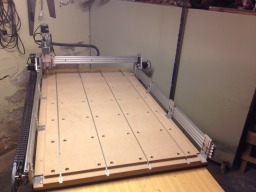

Openbuilds 4x8 cnc

I built this cnc using 2 z axis actuators thinking it would minimize deflection and it seems to be very sturdy. I used 2 1500mm c channels for my x axis, 1 1500mm c channel for my y axis, nema 23 stepper motors, dm556 drivers, 2 24v power supplies, smc5-5-n-n controller, 9mm wide belts, and the Hitachi m12vc router. So far it's working very well with a few hiccups. Programming the controller was a learning experience but I'm very happy with it.

Build Author

MarkM_NJ

Views

20004

Build Author

MarkM_NJ

Views

20004

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Build Author

Michael.M

Views

45294

Build Author

Michael.M

Views

45294

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

Build Author

sebf34

Views

32040

Build Author

sebf34

Views

32040

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

ROUTY CNC Router (V-Slot Belt & Pinion)

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Joe Young

Views

14856

Build Author

Joe Young

Views

14856

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Leonard Cross

Views

38283

Build Author

Leonard Cross

Views

38283

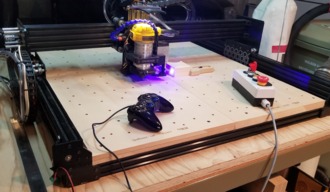

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

Build Author

Savvas

Views

19680

Build Author

Savvas

Views

19680

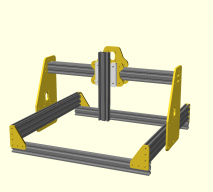

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

Janis93

Views

15714

Build Author

Janis93

Views

15714

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

Rob Taylor

Views

19084

Build Author

Rob Taylor

Views

19084

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Build Author

ahayden

Views

27448

Build Author

ahayden

Views

27448

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

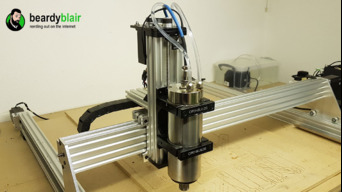

Build Author

beardyblair

Views

25308

Build Author

beardyblair

Views

25308

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

Build Author

Jacob Lotter

Views

27259

Build Author

Jacob Lotter

Views

27259

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

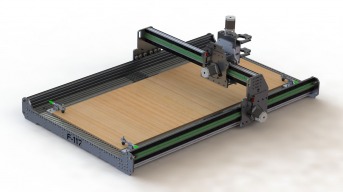

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Build Author

blterry1

Views

19043

Build Author

blterry1

Views

19043

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

Build Author

Robert Hummel

Views

25601

Build Author

Robert Hummel

Views

25601

Stinger V Micro Mill

While building my OX AI I found myself with left over v slot and thought to myself, what do I need that I can build using them? Well since I make a lot of my own PCB boards for projects I figured a micro PCB mill would fit the bill ;) With inspiration from the OX and OX AI I give you the Stinger V :)

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Build Author

that-jim

Views

47904

Build Author

that-jim

Views

47904

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Build Author

Glenn Weston

Views

18306

Build Author

Glenn Weston

Views

18306

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

roadss

Views

26031

Build Author

roadss

Views

26031

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

Gary Caruso

Views

24910

Build Author

Gary Caruso

Views

24910

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Ryan Lock

Views

136273

Build Author

Ryan Lock

Views

136273

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

Build Author

mytechno3d

Views

28148

Build Author

mytechno3d

Views

28148

Router / plasma cutting table ( Rack and pinion )

Heavy DIY plasma cutting table

Charging Ox CNC Machine

A heavily modified Ox CNC build to replace SO2.

Build Author

alex_b

Views

19007

Build Author

alex_b

Views

19007

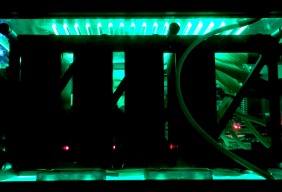

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

Build Author

Ryan Lock

Views

145156

Build Author

Ryan Lock

Views

145156

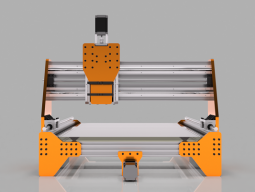

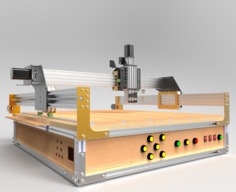

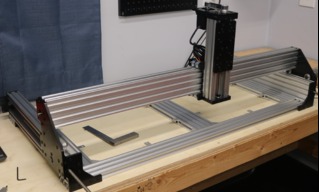

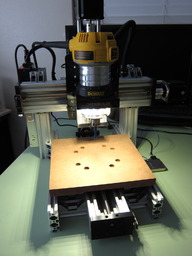

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

Openbuilds C-beam

This is a build supported by Ooznest by a team of girls in Year 8 (12/13 years old) to machine model F1 cars for the F1 in Schools competition.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

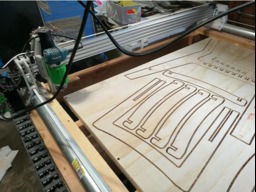

Prototype Rack-n-Pinion 4'x8'

This is a custom gear rack drive machine with a 4'x8' cut capacity.

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

LEAD 1515, HGH15, SFU1604 Ball Screw

Project Completed.

Build Author

Serge E.

Views

61065

Build Author

Serge E.

Views

61065

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Florida Ox 2x4 Area 51 CNC Parts Original Build

2x4 Ox with Vac table

OX Tale

1000mm x 750mm OX with some planned enhancements. My first venture into CNC.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

Build Author

Troy Proffitt

Views

29041

Build Author

Troy Proffitt

Views

29041

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Mark Carew

Views

75536

Build Author

Mark Carew

Views

75536

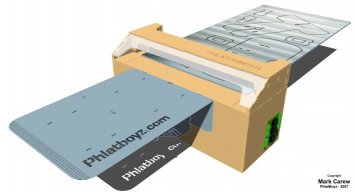

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Build Author

UltiBots

Views

37813

Build Author

UltiBots

Views

37813

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Promoveo Study Builds

Promoteo Build

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

Build Author

SecretSpy711

Views

22594

Build Author

SecretSpy711

Views

22594

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Build Author

Michael.M

Views

9685

Build Author

Michael.M

Views

9685

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Steel Frame CNC Router

A scratch built steel frame CNC Router.

Build Author

Metalguru

Views

14692

Build Author

Metalguru

Views

14692

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Savvas

Views

14429

Build Author

Savvas

Views

14429

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Gooshpoo

Views

9345

Build Author

Gooshpoo

Views

9345

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

Kyo

Views

45738

Build Author

Kyo

Views

45738

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Build Author

nickchnv

Views

12589

Build Author

nickchnv

Views

12589

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

MyCNC(1000mm x 1500mm)

My CNC project

Build Author

Ronald van Arkel

Views

33559

Build Author

Ronald van Arkel

Views

33559

Routy GT2 290 BSX CNC Router, Low Cost and Good!

The Routy GT2 300 BSX CNC Router is a Low Cost CNC build. It performs the same as the larger Routy's from OpenBuilds but doesn't break the bank!

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Build Author

jamesdjadams

Views

12248

Build Author

jamesdjadams

Views

12248

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Mike Campbell

Views

11142

Build Author

Mike Campbell

Views

11142

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Build Author

Matt Nelson

Views

12322

Build Author

Matt Nelson

Views

12322

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

Sword66

Views

14003

Build Author

Sword66

Views

14003

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

Build Author

dreys

Views

11428

Build Author

dreys

Views

11428

Was once a mini mill

Working progress.

Build Author

StrictlyScale

Views

10477

Build Author

StrictlyScale

Views

10477

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

winand

Views

18021

Build Author

winand

Views

18021

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Build Author

Julius

Views

25488

Build Author

Julius

Views

25488

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

OffAxis

Views

7744

Build Author

OffAxis

Views

7744

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

Marco964

Views

9031

Build Author

Marco964

Views

9031

Lead CNC 1510 modified

This is an Openbuilds LEAD 1510, modified to supports a liquid cooled 1.5Kw spindle. The movements are made with lead screw on all three axes.

Build Author

Scott Drake

Views

26570

Build Author

Scott Drake

Views

26570

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

Build Author

Rick 2.0

Views

21101

Build Author

Rick 2.0

Views

21101

C-Beam Mini Mite

A small system with a big bite. Design achieves a good balance between machine size vs. build area, rigidity and ease of construction all while keeping build cost as low as possible.

The Frog: CNC Router

Frog CNC Router. Inspired by OX and "Routy". 24"x36" active working area, approx. 3" usable Z motion.

Tool position setting Part II.

The method used for tool position setting is a matter of personal choice but this is what I do.

Sea-OX

This is my first CNC build. The Sea-OX is a machine built out of three 1000mm C-Beams. I plan to have a Y length of 1000mm and a X length of 650mm. The Z should have the ability to move approximately 100mm.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.