Build List

-

Active Filters:

m

Build Author

pedrofernandez

Views

12191

Build Author

pedrofernandez

Views

12191

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

ZacharyB

Views

5777

Build Author

ZacharyB

Views

5777

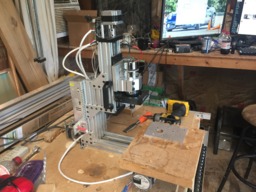

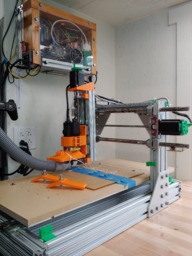

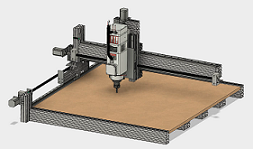

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Dave Pyatt

Views

4525

Build Author

Dave Pyatt

Views

4525

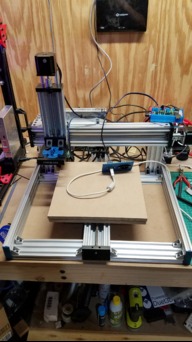

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6450

Build Author

Terone Burgenheim

Views

6450

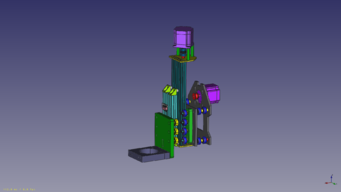

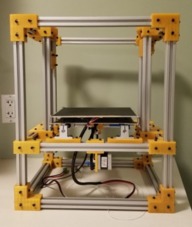

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8463

Build Author

Carl van Heezik

Views

8463

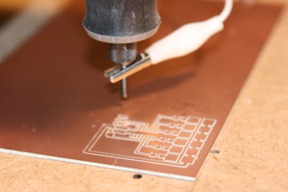

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

MidnightQuads

Views

3912

Build Author

MidnightQuads

Views

3912

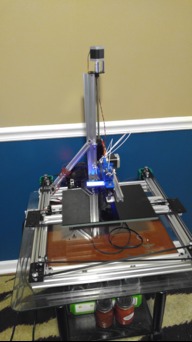

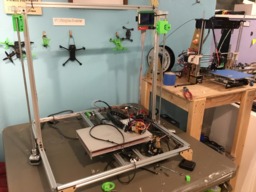

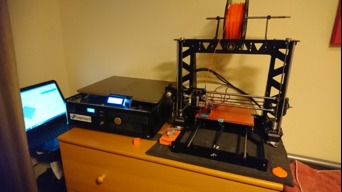

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12378

Build Author

GDanger117

Views

12378

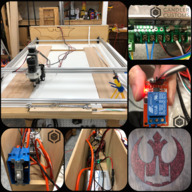

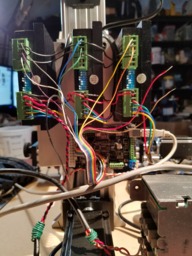

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

9028

Build Author

Lindsey Lewis

Views

9028

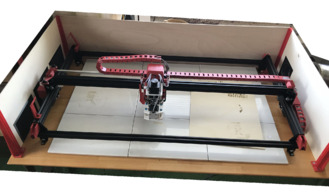

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5458

Build Author

Keith Davis

Views

5458

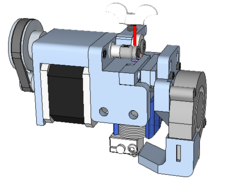

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3785

Build Author

George Motichka

Views

3785

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

6075

Build Author

RJ_Make

Views

6075

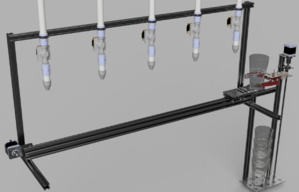

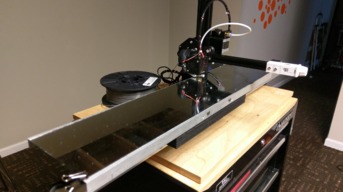

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5576

Build Author

CandlerCustoms

Views

5576

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Camvec

Views

6286

Build Author

Camvec

Views

6286

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

Rodrigo Gonzalez

Views

3661

Build Author

Rodrigo Gonzalez

Views

3661

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Bill325

Views

2357

Build Author

Bill325

Views

2357

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

OffAxis

Views

7758

Build Author

OffAxis

Views

7758

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Nicademus

Views

9589

Build Author

Nicademus

Views

9589

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

5120

Build Author

Rob Withoff

Views

5120

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

JAC_101

Views

6094

Build Author

JAC_101

Views

6094

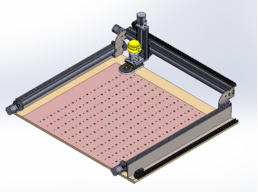

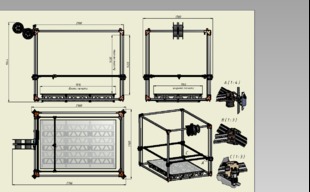

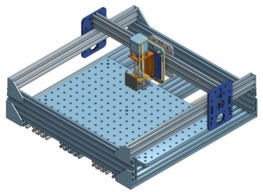

Small PCB, Engraving and Delrin CNC Mill

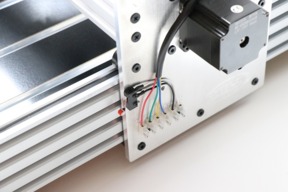

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

Build Author

MattR

Views

20408

Build Author

MattR

Views

20408

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Denis Lapratte

Views

4584

Build Author

Denis Lapratte

Views

4584

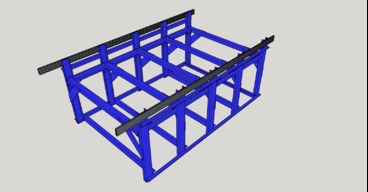

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

Connor Mckeown

Views

6423

Build Author

Connor Mckeown

Views

6423

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

bpatterson42

Views

3584

Build Author

bpatterson42

Views

3584

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

Daniel.korneliussen

Views

3530

Build Author

Daniel.korneliussen

Views

3530

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

TurfnSurf

Views

7157

Build Author

TurfnSurf

Views

7157

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5706

Build Author

spark2

Views

5706

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

Sprags

Views

2752

Build Author

Sprags

Views

2752

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Glenn Weston

Views

11458

Build Author

Glenn Weston

Views

11458

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

jz321

Views

4577

Build Author

jz321

Views

4577

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Liam Dahler

Views

6556

Build Author

Liam Dahler

Views

6556

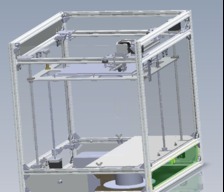

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Build Author

Blyn3D

Views

6406

Build Author

Blyn3D

Views

6406

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

crnrstndes

Views

4251

Build Author

crnrstndes

Views

4251

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Big CNC plasma cutter

more later

Build Author

Bucky Wootmaster

Views

3007

Build Author

Bucky Wootmaster

Views

3007

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

h3rb

Views

3764

Build Author

h3rb

Views

3764

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

obmilllivebuild

Views

5650

Build Author

obmilllivebuild

Views

5650

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

h3rb

Views

5751

Build Author

h3rb

Views

5751

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

pedrofernandez

Views

7936

Build Author

pedrofernandez

Views

7936

ACRO 20x20

The Acro Laser Machine Build

Build Author

John Bolduc

Views

5976

Build Author

John Bolduc

Views

5976

SG Duet Delta

This my version of a large no corners cut Delta.

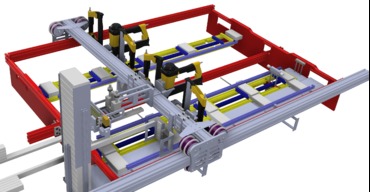

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Build Author

Limine3D

Views

4576

Build Author

Limine3D

Views

4576

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

Tommy Williamson

Views

7027

Build Author

Tommy Williamson

Views

7027

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

Axnfell

Views

3113

Build Author

Axnfell

Views

3113

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Build Author

Brandon Satterfield

Views

7721

Build Author

Brandon Satterfield

Views

7721

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Big-X Minimill

Minimill bundle, but with an extended X Axis

DPR-v2 full metal

pictures and mony doku see later

Acro Pick And Place Machine

This is a machine for placing SMT components on PCBs. It is based on Acro system, off the shelf parts, and a number of custom 3D printed elements.

Delta without vertices

As this is a build in progress, I will update it as I progress.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7181

Build Author

ChrisViral

Views

7181

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

Mark Carew

Views

33880

Build Author

Mark Carew

Views

33880

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Mark Carew

Views

77834

Build Author

Mark Carew

Views

77834

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

28187

Build Author

Mark Carew

Views

28187

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Makerparts Mpro Slider System

Makerparts.ca MPro Camera Slider System

Build Author

Todd Brous

Views

5681

Build Author

Todd Brous

Views

5681

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

Mark Carew

Views

25375

Build Author

Mark Carew

Views

25375

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

reef

Views

12031

Build Author

reef

Views

12031

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

JerwanDavis

Views

6088

Build Author

JerwanDavis

Views

6088

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

Mark Carew

Views

17097

Build Author

Mark Carew

Views

17097

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Carew

Views

18220

Build Author

Mark Carew

Views

18220

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Mark Rehorst

Views

10196

Build Author

Mark Rehorst

Views

10196

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Mark Carew

Views

18404

Build Author

Mark Carew

Views

18404

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Butterfly 3DP V 1.0

tronxy x3 like

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

stepper

Views

4556

Build Author

stepper

Views

4556

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Hilleke

Views

7879

Build Author

Hilleke

Views

7879

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Build Author

mytechno3d

Views

15519

Build Author

mytechno3d

Views

15519

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

SCYBUCK

Views

5140

Build Author

SCYBUCK

Views

5140

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

My Little Mashup

A mixed drive, PI Controlled machine

Build Author

Luke Cunningham

Views

5918

Build Author

Luke Cunningham

Views

5918

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Rob Taylor

Views

10984

Build Author

Rob Taylor

Views

10984

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Build Author

C-CNC

Views

16283

Build Author

C-CNC

Views

16283

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Phil's MiniMill

A quick little mini mill build

Build Author

MrMojoRisin

Views

7616

Build Author

MrMojoRisin

Views

7616

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Mark Carew

Views

6205

Build Author

Mark Carew

Views

6205

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

27333

Build Author

Mark Carew

Views

27333

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

deltajegga

Views

9905

Build Author

deltajegga

Views

9905

THE delta

probably as big as you'd want it...

Build Author

RobFromLDMS

Views

5274

Build Author

RobFromLDMS

Views

5274

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

James Evanko

Views

4859

Build Author

James Evanko

Views

4859

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Build Author

thinman

Views

8819

Build Author

thinman

Views

8819

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.