Build List

-

Active Filters:

a

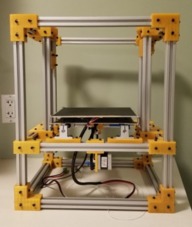

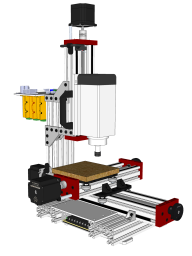

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

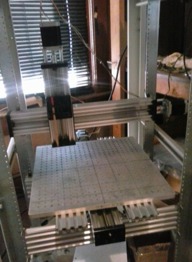

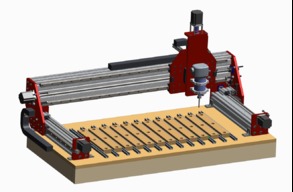

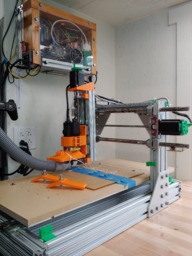

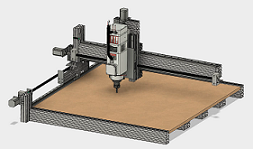

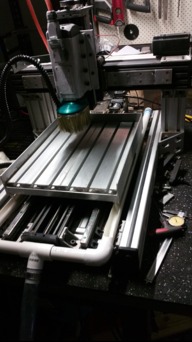

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

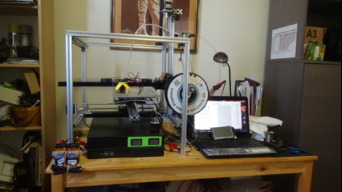

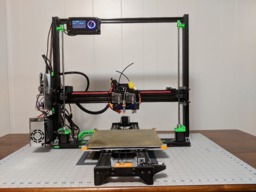

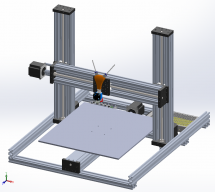

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

C Beam CNC+Laser

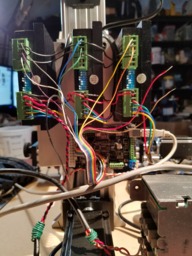

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

V-Slot MAME cabinet

A minimalist MAME "cabinet" made from extrusion.

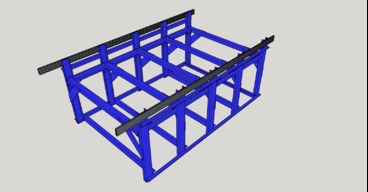

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4033

Build Author

Jason Harding

Views

4033

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

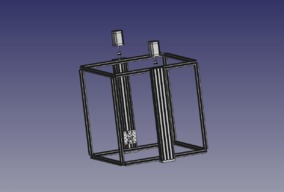

DIY Ultimaker

This design should give the same performance as the high speed Ultimaker since it uses a similar ultra-light X/Y concept which eliminates any movement of both the X and Y motors to achieve X/Y travel.

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Automatic Sprayer

Automatic spray machine.

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

SecretSpy711

Views

22264

Build Author

SecretSpy711

Views

22264

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Anthony Castelluci

Views

3175

Build Author

Anthony Castelluci

Views

3175

Simple Camera Lofted Camera Slider

Build a manual camera slider.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Tucstrlly

Views

8955

Build Author

Tucstrlly

Views

8955

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

New 2 watt laser platform

Acro based 2 watt laser platform

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Build Author

TimVukman

Views

4233

Build Author

TimVukman

Views

4233

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

Kyo

Views

9930

Build Author

Kyo

Views

9930

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

patdee

Views

5012

Build Author

patdee

Views

5012

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Lindsey Lewis

Views

7976

Build Author

Lindsey Lewis

Views

7976

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Build Author

pedrofernandez

Views

12100

Build Author

pedrofernandez

Views

12100

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

ZacharyB

Views

5636

Build Author

ZacharyB

Views

5636

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Dave Pyatt

Views

4440

Build Author

Dave Pyatt

Views

4440

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2751

Build Author

Terone Burgenheim

Views

2751

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6335

Build Author

Terone Burgenheim

Views

6335

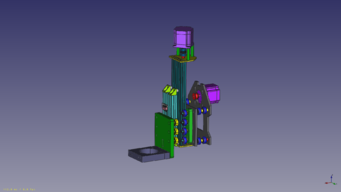

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8246

Build Author

Carl van Heezik

Views

8246

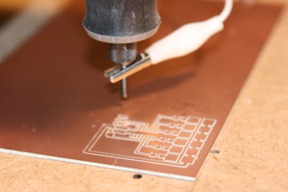

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

cory stafford

Views

4680

Build Author

cory stafford

Views

4680

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

MidnightQuads

Views

3836

Build Author

MidnightQuads

Views

3836

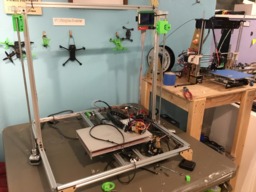

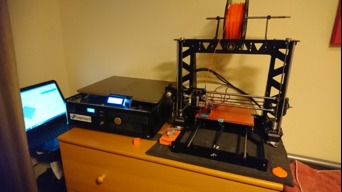

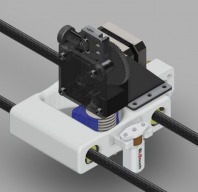

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12184

Build Author

GDanger117

Views

12184

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

8880

Build Author

Lindsey Lewis

Views

8880

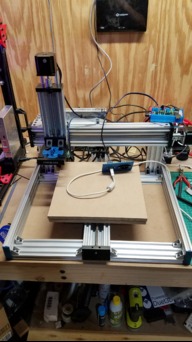

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5348

Build Author

Keith Davis

Views

5348

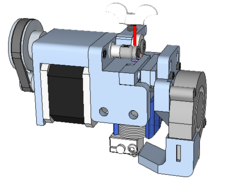

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3712

Build Author

George Motichka

Views

3712

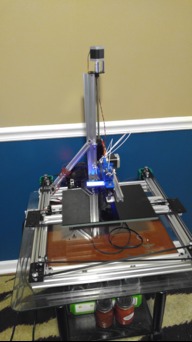

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

5856

Build Author

RJ_Make

Views

5856

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5396

Build Author

CandlerCustoms

Views

5396

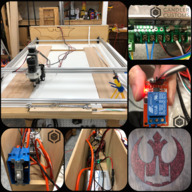

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5710

Build Author

Sam Price

Views

5710

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Camvec

Views

6178

Build Author

Camvec

Views

6178

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

Rodrigo Gonzalez

Views

3533

Build Author

Rodrigo Gonzalez

Views

3533

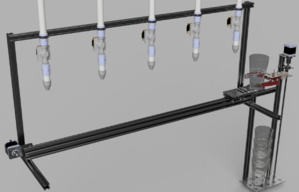

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Bill325

Views

2260

Build Author

Bill325

Views

2260

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

OffAxis

Views

7603

Build Author

OffAxis

Views

7603

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Nicademus

Views

9410

Build Author

Nicademus

Views

9410

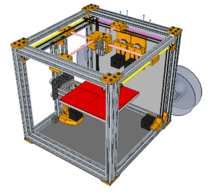

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

4959

Build Author

Rob Withoff

Views

4959

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

TurfnSurf

Views

6143

Build Author

TurfnSurf

Views

6143

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

JAC_101

Views

5956

Build Author

JAC_101

Views

5956

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

MattR

Views

19584

Build Author

MattR

Views

19584

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Denis Lapratte

Views

4461

Build Author

Denis Lapratte

Views

4461

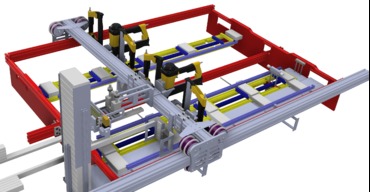

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

D-Bot Version B

D-Bot with a Replicate controller.

Build Author

Connor Mckeown

Views

6281

Build Author

Connor Mckeown

Views

6281

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

bpatterson42

Views

3484

Build Author

bpatterson42

Views

3484

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

Daniel.korneliussen

Views

3424

Build Author

Daniel.korneliussen

Views

3424

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

TurfnSurf

Views

7030

Build Author

TurfnSurf

Views

7030

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5585

Build Author

spark2

Views

5585

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Sprags

Views

2657

Build Author

Sprags

Views

2657

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Glenn Weston

Views

11206

Build Author

Glenn Weston

Views

11206

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

jz321

Views

4443

Build Author

jz321

Views

4443

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Liam Dahler

Views

6431

Build Author

Liam Dahler

Views

6431

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

Blyn3D

Views

6279

Build Author

Blyn3D

Views

6279

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

crnrstndes

Views

4090

Build Author

crnrstndes

Views

4090

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

BinaryConstruct

Views

10117

Build Author

BinaryConstruct

Views

10117

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Big CNC plasma cutter

more later

Build Author

Bucky Wootmaster

Views

2926

Build Author

Bucky Wootmaster

Views

2926

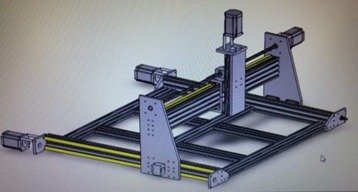

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

h3rb

Views

3668

Build Author

h3rb

Views

3668

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Build Author

obmilllivebuild

Views

5551

Build Author

obmilllivebuild

Views

5551

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

h3rb

Views

5573

Build Author

h3rb

Views

5573

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

pedrofernandez

Views

7819

Build Author

pedrofernandez

Views

7819

ACRO 20x20

The Acro Laser Machine Build

Build Author

John Bolduc

Views

5850

Build Author

John Bolduc

Views

5850

SG Duet Delta

This my version of a large no corners cut Delta.

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

Build Author

Limine3D

Views

4426

Build Author

Limine3D

Views

4426

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)