Build List

-

Active Filters:

tr

Build Author

Stan Howe

Views

3476

Build Author

Stan Howe

Views

3476

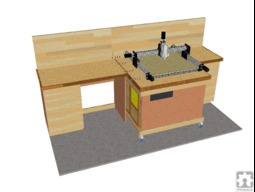

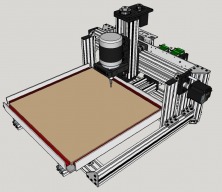

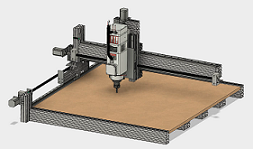

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

MarkM_NJ

Views

20178

Build Author

MarkM_NJ

Views

20178

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Build Author

Cortellini

Views

5790

Build Author

Cortellini

Views

5790

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Build Author

Spark Concepts

Views

5560

Build Author

Spark Concepts

Views

5560

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Build Author

crystaldragon141

Views

6728

Build Author

crystaldragon141

Views

6728

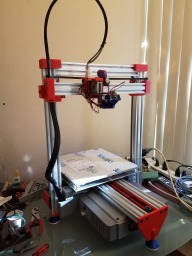

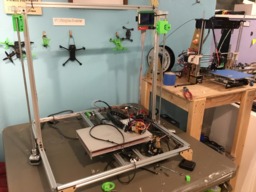

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

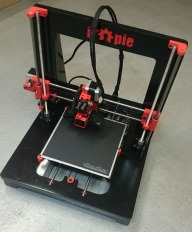

iTopie RepRap - 3D Printer

A stable and strong 3D printer made of 16mm MDF and machined on my OX.

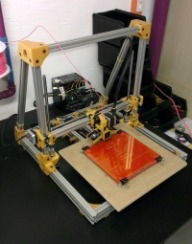

Butterfly 3DP V 1.0

tronxy x3 like

Build Author

Mark Carew

Views

6340

Build Author

Mark Carew

Views

6340

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Lautr3k RepRap

A 3D printer without belts, a print volume of 320x320x260mm, obviously the V-Slot as linear guide! and a maximum of printed pieces.

Build Author

Metalguru

Views

14996

Build Author

Metalguru

Views

14996

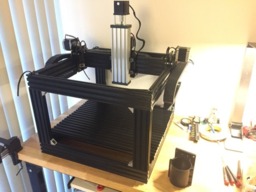

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Christian James

Views

10398

Build Author

Christian James

Views

10398

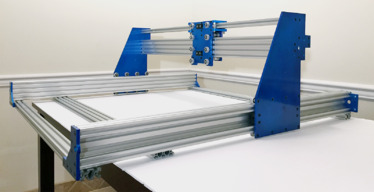

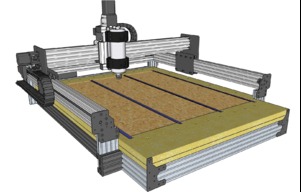

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Joe Young

Views

6101

Build Author

Joe Young

Views

6101

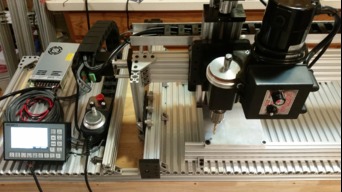

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

TurfnSurf

Views

7309

Build Author

TurfnSurf

Views

7309

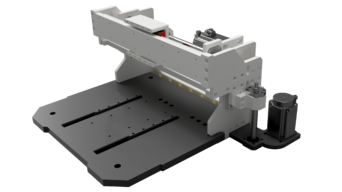

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Jacob Lotter

Views

6237

Build Author

Jacob Lotter

Views

6237

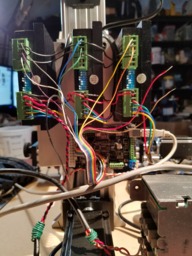

CNC ESS Controls System

My Controls box to run my Workbee 1510 That was retrofitted with Lead Screws as well as Lineal Bearings. The stock electrical configuration was not enough, so here are the Measures that I took to not only make this machine Run again, but to have fun with it, and make this system be able to run any CNC I run in the future with the installed microcontroller.

Build Author

Lumberjack Engineering

Views

20403

Build Author

Lumberjack Engineering

Views

20403

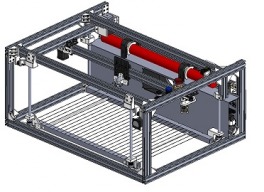

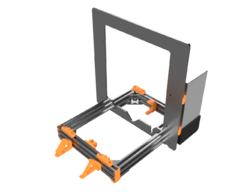

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Build Author

MrMojoRisin

Views

7764

Build Author

MrMojoRisin

Views

7764

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Build Author

Savvas

Views

19143

Build Author

Savvas

Views

19143

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Build Author

Eric Jacobsson

Views

15739

Build Author

Eric Jacobsson

Views

15739

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Connor Mckeown

Views

6583

Build Author

Connor Mckeown

Views

6583

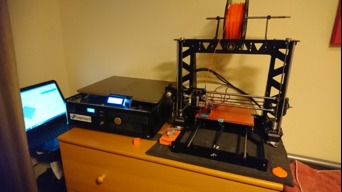

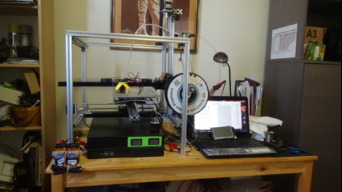

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

Rob Mahan

Views

14233

Build Author

Rob Mahan

Views

14233

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

Lindsey Lewis

Views

8466

Build Author

Lindsey Lewis

Views

8466

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

James Evanko

Views

4256

Build Author

James Evanko

Views

4256

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Build Author

Robert E. Nee

Views

17977

Build Author

Robert E. Nee

Views

17977

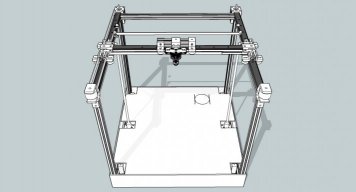

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Build Author

James Evanko

Views

5072

Build Author

James Evanko

Views

5072

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

Rick Holder

Views

15606

Build Author

Rick Holder

Views

15606

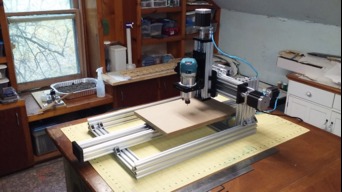

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

Luke Cunningham

Views

6013

Build Author

Luke Cunningham

Views

6013

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

SCYBUCK

Views

5240

Build Author

SCYBUCK

Views

5240

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

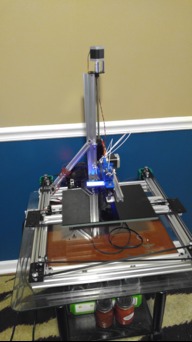

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Michael.M

Views

9861

Build Author

Michael.M

Views

9861

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

MikieLikesIt

Views

8392

Build Author

MikieLikesIt

Views

8392

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

Nicademus

Views

9912

Build Author

Nicademus

Views

9912

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

stepper

Views

4705

Build Author

stepper

Views

4705

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Build Author

Carl Siren

Views

7801

Build Author

Carl Siren

Views

7801

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

thehans

Views

6858

Build Author

thehans

Views

6858

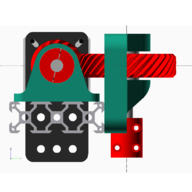

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

BinaryConstruct

Views

10389

Build Author

BinaryConstruct

Views

10389

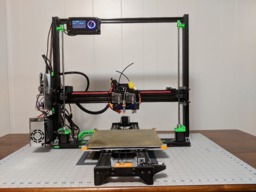

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Sword66

Views

14250

Build Author

Sword66

Views

14250

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

Build Author

Sprags

Views

2859

Build Author

Sprags

Views

2859

C-Beam Kyo Sphinx 10060

More stuff here.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

TurfnSurf

Views

6334

Build Author

TurfnSurf

Views

6334

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

Keith Davis

Views

5568

Build Author

Keith Davis

Views

5568

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

Hussein Dermay

Views

6735

Build Author

Hussein Dermay

Views

6735

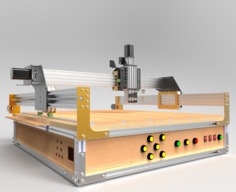

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

Janis93

Views

16035

Build Author

Janis93

Views

16035

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

Tommy Williamson

Views

7332

Build Author

Tommy Williamson

Views

7332

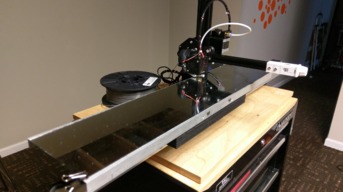

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Calotype

Views

3685

Build Author

Calotype

Views

3685

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

Andre Cooke

Views

17879

Build Author

Andre Cooke

Views

17879

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Gooshpoo

Views

9605

Build Author

Gooshpoo

Views

9605

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

h3rb

Views

5999

Build Author

h3rb

Views

5999

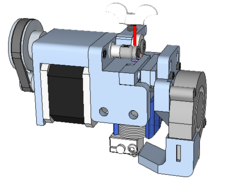

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Naomi Wu

Views

11059

Build Author

Naomi Wu

Views

11059

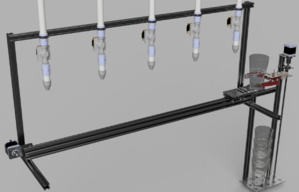

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

TimVukman

Views

4422

Build Author

TimVukman

Views

4422

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

Blyn3D

Views

6602

Build Author

Blyn3D

Views

6602

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

Bucky Wootmaster

Views

3116

Build Author

Bucky Wootmaster

Views

3116

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

OffAxis

Views

7963

Build Author

OffAxis

Views

7963

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

crnrstndes

Views

4371

Build Author

crnrstndes

Views

4371

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

JAC_101

Views

6229

Build Author

JAC_101

Views

6229

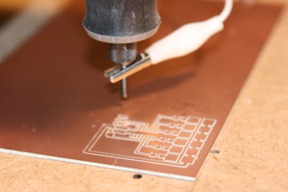

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Build Author

jz321

Views

4714

Build Author

jz321

Views

4714

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

spark2

Views

5880

Build Author

spark2

Views

5880

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Rob Withoff

Views

5314

Build Author

Rob Withoff

Views

5314

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Daniel.korneliussen

Views

3621

Build Author

Daniel.korneliussen

Views

3621

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

Denis Lapratte

Views

4742

Build Author

Denis Lapratte

Views

4742

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

bpatterson42

Views

3708

Build Author

bpatterson42

Views

3708

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

pek

Views

27352

Build Author

pek

Views

27352

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

Build Author

Camvec

Views

6410

Build Author

Camvec

Views

6410

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

D-Bot Version B

D-Bot with a Replicate controller.

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

Rodrigo Gonzalez

Views

3774

Build Author

Rodrigo Gonzalez

Views

3774

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

Dave Pyatt

Views

4655

Build Author

Dave Pyatt

Views

4655

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Carl van Heezik

Views

8680

Build Author

Carl van Heezik

Views

8680

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

Bill325

Views

2470

Build Author

Bill325

Views

2470

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

GDanger117

Views

12648

Build Author

GDanger117

Views

12648

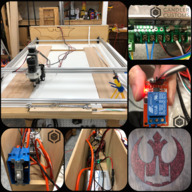

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Chetan PM

Views

3946

Build Author

Chetan PM

Views

3946

Composer

Gantry style rigid build

Build Author

ShockingTops

Views

4608

Build Author

ShockingTops

Views

4608

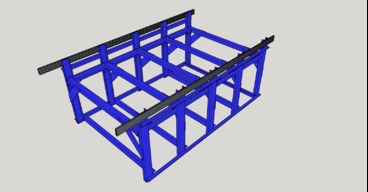

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Build Author

jtaggard

Views

37898

Build Author

jtaggard

Views

37898

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

Build Author

George Motichka

Views

3885

Build Author

George Motichka

Views

3885

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

CandlerCustoms

Views

5767

Build Author

CandlerCustoms

Views

5767

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

RJ_Make

Views

6325

Build Author

RJ_Make

Views

6325

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

Ronald van Arkel

Views

16826

Build Author

Ronald van Arkel

Views

16826

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

cory stafford

Views

4868

Build Author

cory stafford

Views

4868

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

MidnightQuads

Views

4012

Build Author

MidnightQuads

Views

4012

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

Terone Burgenheim

Views

6618

Build Author

Terone Burgenheim

Views

6618

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Terone Burgenheim

Views

2900

Build Author

Terone Burgenheim

Views

2900

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

ZacharyB

Views

5902

Build Author

ZacharyB

Views

5902

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

patdee

Views

5267

Build Author

patdee

Views

5267

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

William Niedermeyer

Views

19910

Build Author

William Niedermeyer

Views

19910

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Ancient Roland Table top Mill

The parts are now very reasonable.