Build List

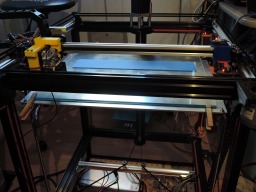

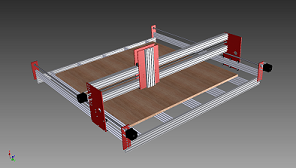

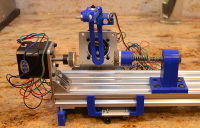

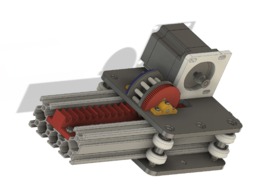

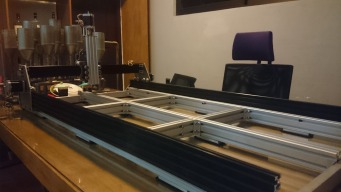

C-beam Camera slider

feel kind of bad calling this a build because of pretty much everything is off the shelf parts. I'm writing my own sketch right now for the motion but there is a version or 2 floating around on the net based of this design. I will post my code once it's done.

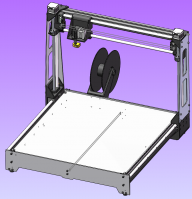

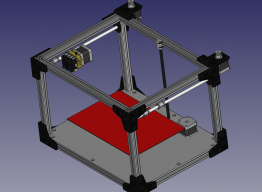

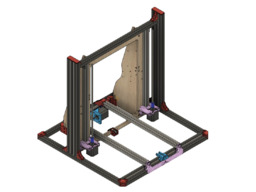

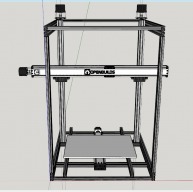

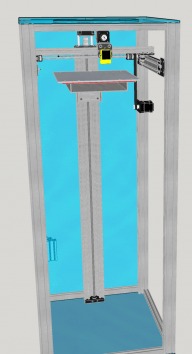

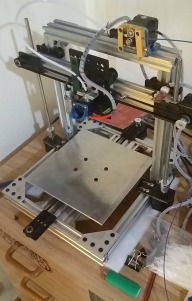

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

Michael.M

Views

9691

Build Author

Michael.M

Views

9691

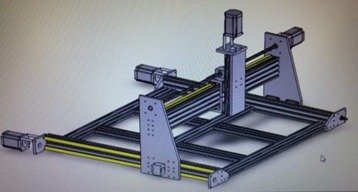

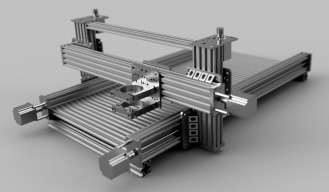

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

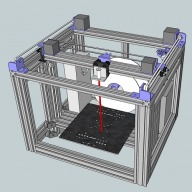

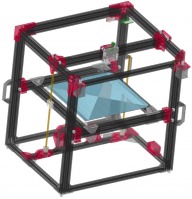

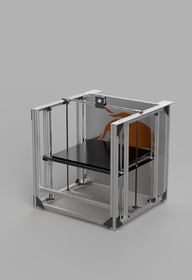

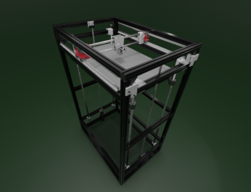

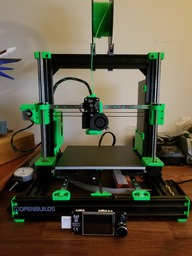

BldrBox

OpenBuilds box type printer using min-v-wheels for X & Y axis. Designed for plexiglas panel enclosure of build area.

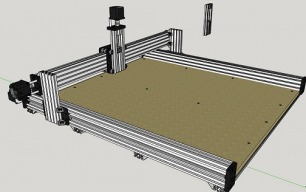

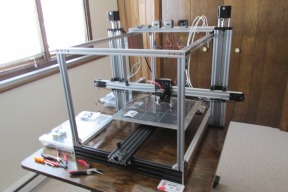

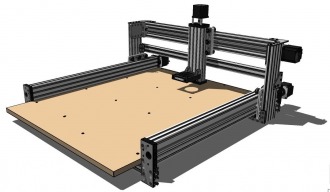

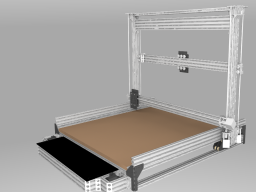

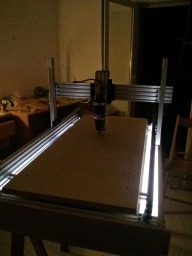

OX Build

Standard OX Build

Build Author

Asaku

Views

9663

Build Author

Asaku

Views

9663

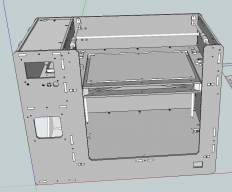

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Nicademus

Views

9584

Build Author

Nicademus

Views

9584

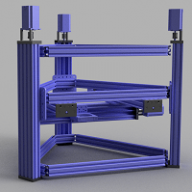

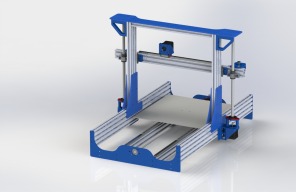

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Quentin Karmark

Views

9462

Build Author

Quentin Karmark

Views

9462

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

Christer Langley

Views

9459

Build Author

Christer Langley

Views

9459

CNC-Solutions Build

My first Build with V-slot

Kool Bot

Mid range build.

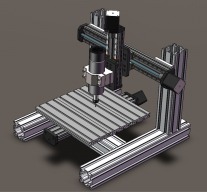

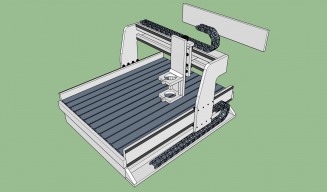

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

Build Author

Colin Russon

Views

9441

Build Author

Colin Russon

Views

9441

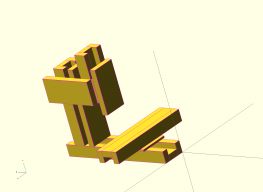

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

Rwetzler

Views

9389

Build Author

Rwetzler

Views

9389

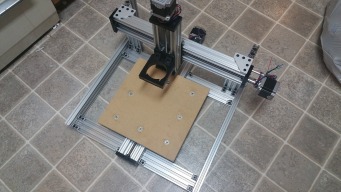

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Fun and Functional Laser Build

A very fun and fulfilling build. I can't say enough about the whole Open Builds site and Open Source movement. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor.

Build Author

Gooshpoo

Views

9349

Build Author

Gooshpoo

Views

9349

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

Sergio Di Ventura

Views

9336

Build Author

Sergio Di Ventura

Views

9336

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

zann68

Views

9324

Build Author

zann68

Views

9324

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

openhardwarecoza

Views

9300

Build Author

openhardwarecoza

Views

9300

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

Mike Andrews

Views

9299

Build Author

Mike Andrews

Views

9299

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Pol Feliu

Views

9276

Build Author

Pol Feliu

Views

9276

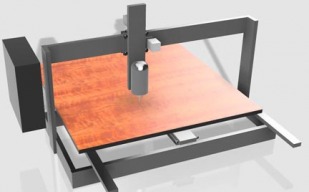

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

Greg Lampman

Views

9238

Build Author

Greg Lampman

Views

9238

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Justin Butler

Views

9233

Build Author

Justin Butler

Views

9233

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

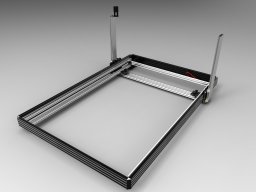

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

MiniMill

Building a small mill to match my 7x12 lathe.

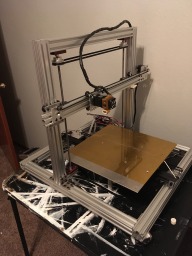

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

J-Wahl Dezign

Views

9153

Build Author

J-Wahl Dezign

Views

9153

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

boutrous

Views

9132

Build Author

boutrous

Views

9132

Laser Rotary Attachment

Build Summary updated after parts list completed

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

Build Author

motopreserve

Views

9102

Build Author

motopreserve

Views

9102

Persnickety Plate Maker

My very first attempt at a CNC build. Based on the OpenBuilds C-Beam Machine, small tweaks will be made to tailor it for my goals: machining G10, aluminum & some carbon fiber for use with multirotor and motorcycle parts. I am looking forward to the day when I am comfortable enough to bring the ideas in my head to the tip of the end mill in a smooth fashion...

Build Author

Tucstrlly

Views

9092

Build Author

Tucstrlly

Views

9092

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

Build Author

Anglesachse

Views

9060

Build Author

Anglesachse

Views

9060

Zorkbot

Corexy, with possible head change (3d, cnc, laser)

Build Author

sgspenceley

Views

9007

Build Author

sgspenceley

Views

9007

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Build Author

Richard Bugland

Views

9003

Build Author

Richard Bugland

Views

9003

Heavy Inexpensive CNC

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

OX 1500x1500 Dual Drive

Ox inspired 1500 x 1500 CNC with belt and pinion drive and lead screw drive options.

Linear Rail derivative with ball screw

basic start to design of cnc machine

CNC CARDBOARD BOX CUTTER

Just an easy build .... uncomplicated.... simple tools .... but hoping for a good result!

Build Author

Karan Singh Sisodia

Views

8915

Build Author

Karan Singh Sisodia

Views

8915

CNC Laser

CoreXY based CNC Laser machine.

Build Author

evildean

Views

8913

Build Author

evildean

Views

8913

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Phoenix Alpha

Hobby project

5 x 10 CNC - Sub $3000 - Wall Mountable

I wanted a 5 x 10, Wall mounted CNC, that cost less than $3000. I think Im pretty close.

Build Author

Hisha

Views

8881

Build Author

Hisha

Views

8881

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

CoreXZ

I am building a H bot style printer so this design will not be finished any more than it is.

Build Author

DiggerJ

Views

8786

Build Author

DiggerJ

Views

8786

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

core xy smoothie

i had som left over parts and i dit like to test the corexy control so this is wat i came up with. sorry bad englich.

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

Build Author

CWidt

Views

8745

Build Author

CWidt

Views

8745

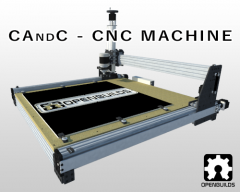

OpenBuilds CAndC - CNC Machine

A new derivative of the famous OX CNC, with increases strength, rigidity, and accuracy.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

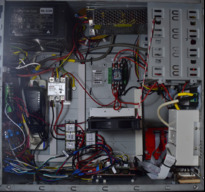

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Build Author

Colin Russon

Views

8711

Build Author

Colin Russon

Views

8711

RoboFoamCutter

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

Pick and place

Openbuilds Pick and Place using ideas from OpenPNP Frame work is from the Openbuilds Part store using 1000mm C beams and vslot 40x40 for support Surface is 3/4 " Particle board

Build Author

taratata2016

Views

8631

Build Author

taratata2016

Views

8631

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Cbeam Digital Mitre Saw Fence

Work in progress.. but nearing completion :)

Build Author

Limine3D

Views

8578

Build Author

Limine3D

Views

8578

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Neptunes Guitars

Views

8531

Build Author

Neptunes Guitars

Views

8531

Neptunes Ox

First build of CNC OX for the purpose of using it for Guitar building to take a lot of the muscle work out so I can concentrate on the finer details.

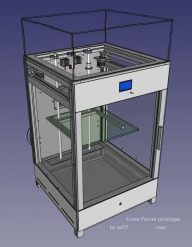

Tower Printer

Tower Printer H-Belt type printer Prototype

Build Author

John J Talavera

Views

8487

Build Author

John J Talavera

Views

8487

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Mandarin-Bot :)

Another slight variation of Niko's Eggbot using Openbuilds V-slot and other 3d printed parts.

K40 upgrades

Cheap chinese K40 laser upgrades, including 60x30cm working area, MKS or SKR controllerboard (smoothieware or marlin, not yet decided.) Light, psu and a bit more :)

Schematix OX metal build

OX metal build from an noob

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Build Author

Carl van Heezik

Views

8456

Build Author

Carl van Heezik

Views

8456

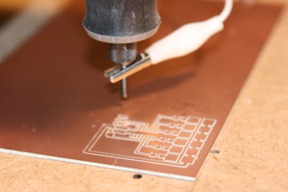

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

Build Author

MikieLikesIt

Views

8268

Build Author

MikieLikesIt

Views

8268

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

richthorn

Views

8267

Build Author

richthorn

Views

8267

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

DoubleX

This is a Dual X-axis platform.

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

Julius

Views

8215

Build Author

Julius

Views

8215

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

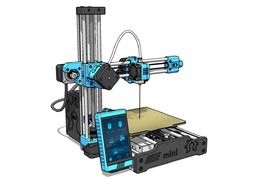

ME-Mini 3D Printer

Prusa mini inspired 3d printer

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

CO2 laser cutter

A build which is based on a metal frame and aluminium plate which I salvaged from a skip. The frame is sized to hold 19" rack units so I'll build my control box into a 3U rack unit (also salvaged). The area available for the build is 700x1200mm. I'll sling a 60W CO2 tube under the base, the beam path will be initially upward into the enclosure.

Build Author

Jay Almers

Views

8047

Build Author

Jay Almers

Views

8047

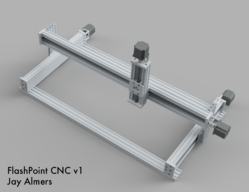

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Large Laser cut table build

Large 6 x 10 foot laser table build. New to building CNC

RRP - Roller Rack Pinion System

Current progress uses existing openbuilds bearings, but also uses 8mm shafts (custom)

Build Author

holographic

Views

7941

Build Author

holographic

Views

7941

Laser DIY

How i construct and create my DIY Co2 Laser cutter and engraving mashine. details will follow

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

Build Author

David E. Flores E.

Views

7832

Build Author

David E. Flores E.

Views

7832

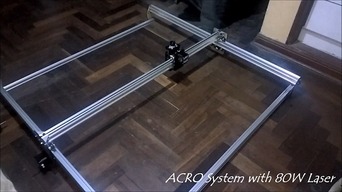

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

Build Author

Sam Dobbie

Views

7817

Build Author

Sam Dobbie

Views

7817

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Build Author

d0rk1e

Views

7783

Build Author

d0rk1e

Views

7783

OXford (OX fortified)

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

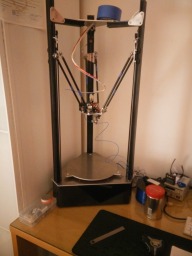

3D Printer DELTA

Delta printer, Bed size 280 cm dimeter Print Height 300 cm not tested yet the speed

First CNC Router

My very first CNC Router build. It's completely scratch built.

Build Author

OffAxis

Views

7748

Build Author

OffAxis

Views

7748

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

Weldsmith

Views

7730

Build Author

Weldsmith

Views

7730

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Add more V-Slot to my Makerfarm 10" Prusa i3v

Upgrade my 5 year old Makerfarm printer to use more V-Slot