Build List

Build Author

TimVukman

Views

4318

Build Author

TimVukman

Views

4318

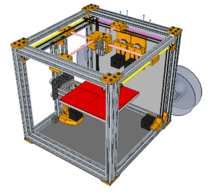

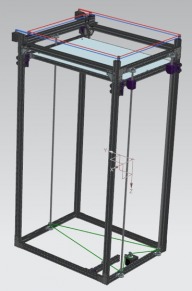

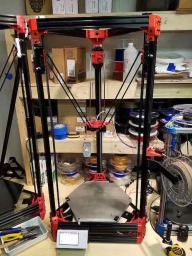

Unique Z

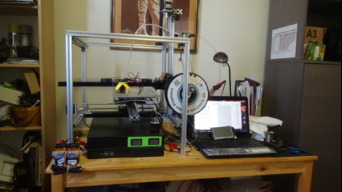

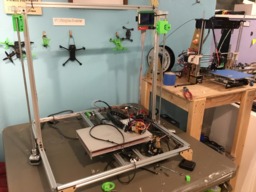

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

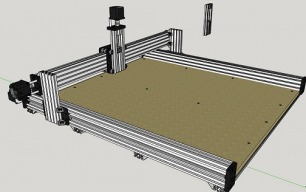

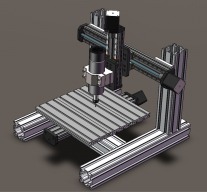

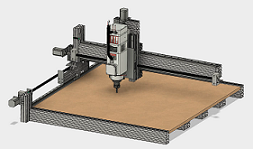

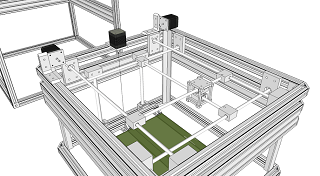

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Jose A. Molina

Views

6955

Build Author

Jose A. Molina

Views

6955

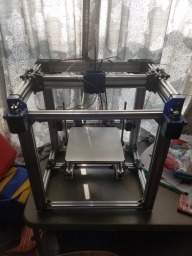

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Big CNC plasma cutter

more later

Build Author

Blyn3D

Views

6397

Build Author

Blyn3D

Views

6397

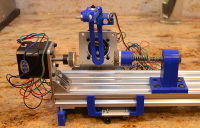

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

Bucky Wootmaster

Views

3004

Build Author

Bucky Wootmaster

Views

3004

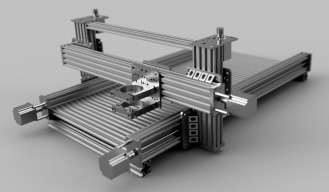

Bucky CNC

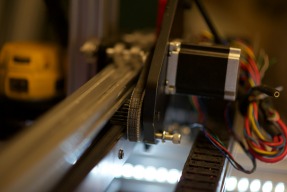

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

OffAxis

Views

7748

Build Author

OffAxis

Views

7748

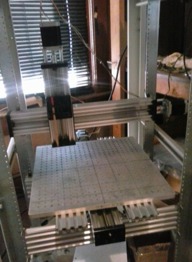

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

spark2

Views

5700

Build Author

spark2

Views

5700

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Rob Withoff

Views

5115

Build Author

Rob Withoff

Views

5115

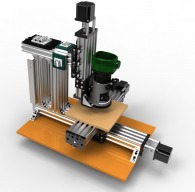

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

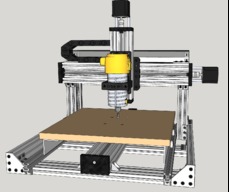

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

ACRO 150 X 150 CM

Openbuilds ACRO

Build Author

Daniel.korneliussen

Views

3528

Build Author

Daniel.korneliussen

Views

3528

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

Denis Lapratte

Views

4578

Build Author

Denis Lapratte

Views

4578

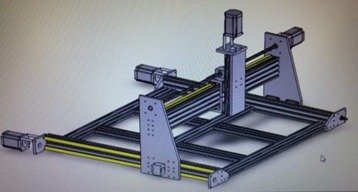

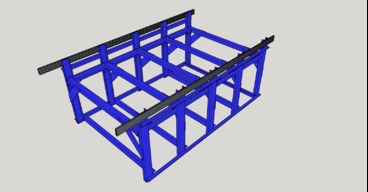

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

bpatterson42

Views

3583

Build Author

bpatterson42

Views

3583

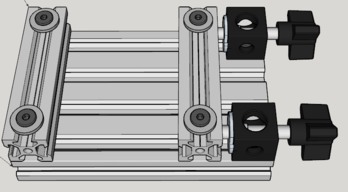

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

Camvec

Views

6278

Build Author

Camvec

Views

6278

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

D-Bot Version B

D-Bot with a Replicate controller.

Build Author

Rodrigo Gonzalez

Views

3659

Build Author

Rodrigo Gonzalez

Views

3659

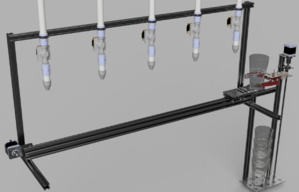

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Dave Pyatt

Views

4524

Build Author

Dave Pyatt

Views

4524

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Carl van Heezik

Views

8456

Build Author

Carl van Heezik

Views

8456

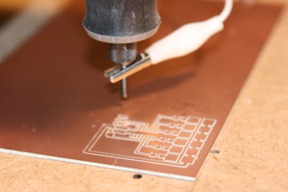

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

Bill325

Views

2351

Build Author

Bill325

Views

2351

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

Teflon4

Views

15951

Build Author

Teflon4

Views

15951

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Bud Griffin

Views

11641

Build Author

Bud Griffin

Views

11641

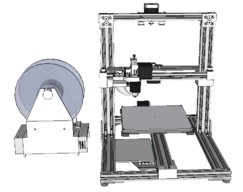

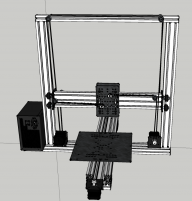

BF3D OX (Big Freakin' 3D OX)

This is my latest printer build. The second printer I've built using V-Slot.

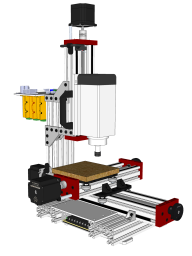

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

brw_racing

Views

16273

Build Author

brw_racing

Views

16273

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

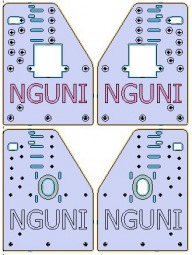

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

Build Author

Ronald van Arkel

Views

16638

Build Author

Ronald van Arkel

Views

16638

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

cory stafford

Views

4790

Build Author

cory stafford

Views

4790

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

JWhitten

Views

14141

Build Author

JWhitten

Views

14141

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Jens Grabner

Views

4149

Build Author

Jens Grabner

Views

4149

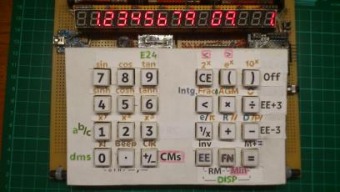

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

Build Author

MidnightQuads

Views

3912

Build Author

MidnightQuads

Views

3912

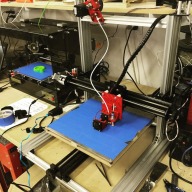

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

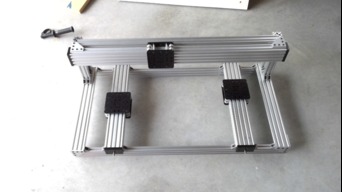

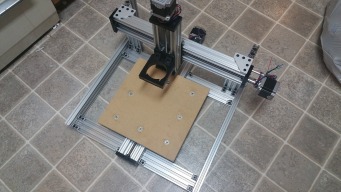

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Build Author

Tucstrlly

Views

9092

Build Author

Tucstrlly

Views

9092

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

patdee

Views

5119

Build Author

patdee

Views

5119

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

William Niedermeyer

Views

19669

Build Author

William Niedermeyer

Views

19669

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

Ancient Roland Table top Mill

The parts are now very reasonable.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

Joerharris

Views

6572

Build Author

Joerharris

Views

6572

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Build Author

ymilord

Views

19456

Build Author

ymilord

Views

19456

Small Portable PCB CNC Machine (CoreXY)

This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

Build Author

CubeSpawn

Views

19789

Build Author

CubeSpawn

Views

19789

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

Build Author

ymilord

Views

12735

Build Author

ymilord

Views

12735

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

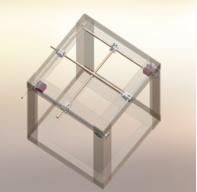

DIY Ultimaker

This design should give the same performance as the high speed Ultimaker since it uses a similar ultra-light X/Y concept which eliminates any movement of both the X and Y motors to achieve X/Y travel.

Build Author

Karan Singh Sisodia

Views

8915

Build Author

Karan Singh Sisodia

Views

8915

CNC Laser

CoreXY based CNC Laser machine.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Mini D-Bot

A smaller version of a standard D-bot. Smaller to fit better in my workable area and to fit my vision for the printer.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

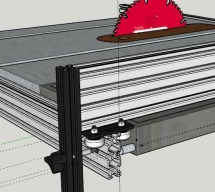

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

Easy to build and robust 3D printer framework

Lord willing I will be showing you how build a robust and easy to build 3D printer framework using V-Slot rails and rollers. It's a little bulky, but it has all spring tensioned rollers on all axes, and can be built entirely without custom machining on any parts. You will need digital calipers, a drill press, a carbide toothed miter saw for cutting aluminum extrusions, and lots of little screws!

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Nebraska 1246 x 1184

This is my first attempt at a CNC anything build

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

D-BOT With Mods

What a way to learn about 3D printing

Lead screw printer

High quality e3d parts with a minimalist design

Mandarin-Bot :)

Another slight variation of Niko's Eggbot using Openbuilds V-slot and other 3d printed parts.

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4098

Build Author

Jason Harding

Views

4098

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Build Author

francesco pollina

Views

7147

Build Author

francesco pollina

Views

7147

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.

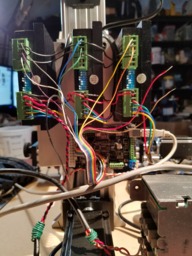

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Build Author

Hisha

Views

8881

Build Author

Hisha

Views

8881

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

Greg Lampman

Views

9238

Build Author

Greg Lampman

Views

9238

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Build Author

Martin Bogomolni

Views

12295

Build Author

Martin Bogomolni

Views

12295

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)