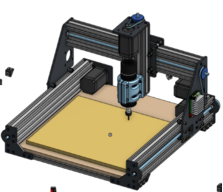

Cartesian Style CNC

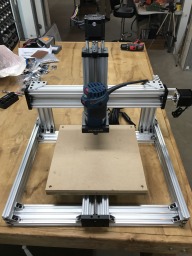

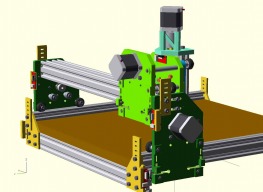

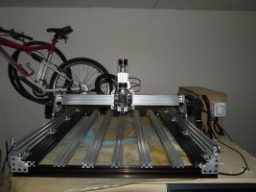

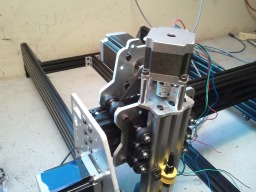

Ooznest Moded CNC

Modded OX with full nema23 4 point support

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Build Author

Matt Barile

Views

7538

Build Author

Matt Barile

Views

7538

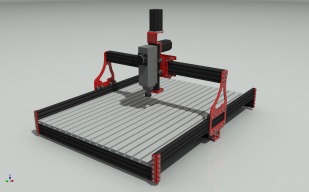

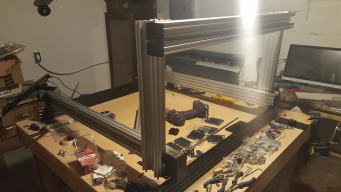

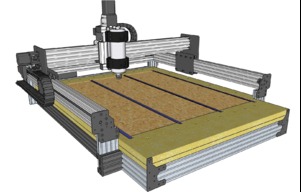

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

Shaun Weitzel

Views

7522

Build Author

Shaun Weitzel

Views

7522

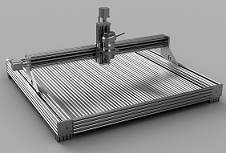

OpenBuilds Lead 1515

First build of a Lead 1515!

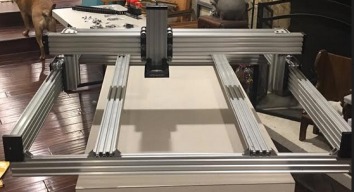

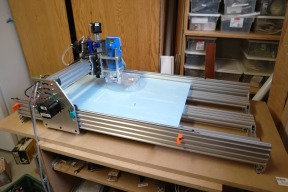

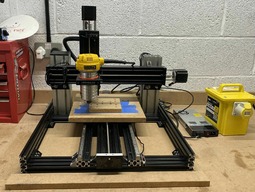

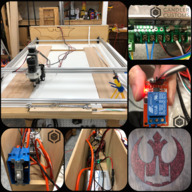

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

My Little OX

This build has been an educational experience. Software and hardware alike.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

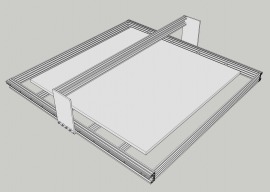

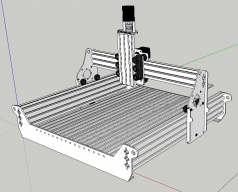

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Brokkr CNC 2.0

1M C-beam xy variant

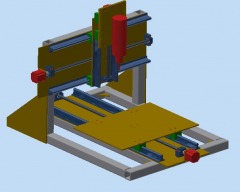

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Build Author

Vin1027

Views

7362

Build Author

Vin1027

Views

7362

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

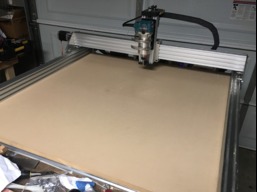

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

TurfnSurf

Views

7157

Build Author

TurfnSurf

Views

7157

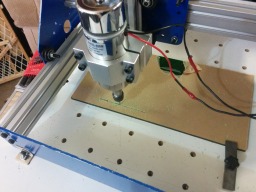

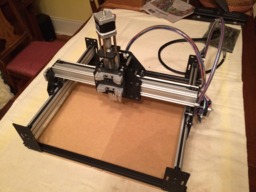

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

CNC MILLING ROUTER

CNC MILLING ROUTER

Build Author

openhardwarecoza

Views

7141

Build Author

openhardwarecoza

Views

7141

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

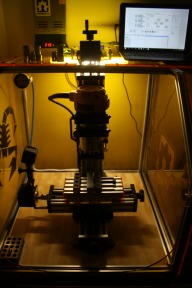

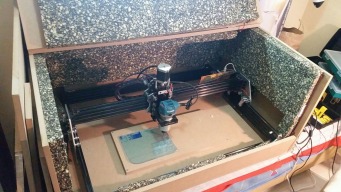

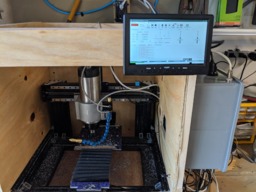

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Birdie CNC

OpenBuilds CNC 500x500

Build Author

Fábio Pires

Views

7068

Build Author

Fábio Pires

Views

7068

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Build Author

Stokrotka74

Views

6962

Build Author

Stokrotka74

Views

6962

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

Build Author

Hytech2k

Views

6961

Build Author

Hytech2k

Views

6961

Micro Ox 2 x 2

Micro Ox Build

Small Red OX

A small router for thin plate stock

Build Author

joetemus

Views

6862

Build Author

joetemus

Views

6862

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

CONUCON

Views

6853

Build Author

CONUCON

Views

6853

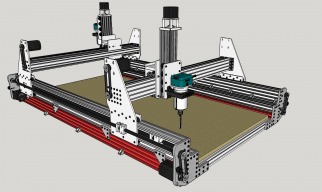

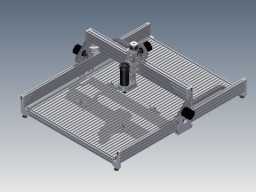

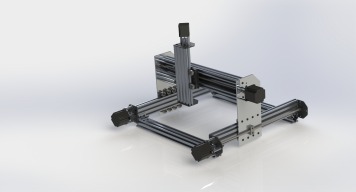

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

HardKnot OX 4x4

I've been working on commercial woodworking CNC's for year's under shop owner's that didn't want me to progress any further at a certain point. This is a project I've wanting to build for about 10 years now. I can't wait for the freedom to build what I know is possible without any negative input.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

My Shapeoko Router build

I built this as it is a small portable design.

Aluminium Router From Dubai

Another modification on the OX

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Modified OX CNC Router (1000x750 mm)

An OX Router I'd like to modify to improve the frame rigidity and resolve some alignment problems

Build Author

Joerharris

Views

6573

Build Author

Joerharris

Views

6573

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Hussein Dermay

Views

6531

Build Author

Hussein Dermay

Views

6531

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

My build

I am satisfied with my build and next one will be even better.

Build Author

Zootalaws

Views

6480

Build Author

Zootalaws

Views

6480

OXENlarged

This is a 1500 x 1500 Ox build

OX based lead screw Machine

Initial design for my CNC mill\router based around C beams

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

Camvec

Views

6288

Build Author

Camvec

Views

6288

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

Build Author

TurfnSurf

Views

6227

Build Author

TurfnSurf

Views

6227

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

inhan

Views

6215

Build Author

inhan

Views

6215

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Build Author

Gary Bonard

Views

6190

Build Author

Gary Bonard

Views

6190

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

msdosfx

Views

6178

Build Author

msdosfx

Views

6178

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

TAZ C-Beam CnC Router by RC-CnC

C-Beam inspired CnC Router (1000x750) Approx 90mm of Z travel

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Black gear 1500X3000

My cnc update and rebuild.

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

KerryH's OX

My adventure in CNC routing.

Custom Ox

Custom black and red Big Ox

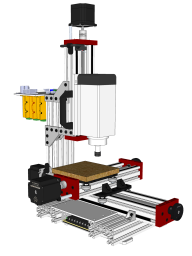

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Router / Plasma Prototype Build

this is my first attempt at a CNC Table

The Beast

1000mm x 1000mm linear rails, double gantry, build in Process... more to come

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Build Author

Paul Amelang

Views

5738

Build Author

Paul Amelang

Views

5738

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Wakezor

I'm starting my first own build cnc machine which is inspired by routy and the ox. Were my goal was not to use the ox plates but use the standard plates available in the parts store for the design.

Build Author

spark2

Views

5707

Build Author

spark2

Views

5707

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

1515 Deluxe

Build features include a double c-beam gantry (bonded & mechanically fastened), linear x rails, custom gantry end plates, a custom linear rail & ballscrew Z axis, and custom lead screw tensioning plates. The primary goal was to remove twist from the 1500mm gantry & stiffen the Z axis.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

Donald D. Parker

Views

5671

Build Author

Donald D. Parker

Views

5671

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Build Author

Cortellini

Views

5609

Build Author

Cortellini

Views

5609

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

Build Author

CandlerCustoms

Views

5579

Build Author

CandlerCustoms

Views

5579

Candler Customs - Custom CNC Machine

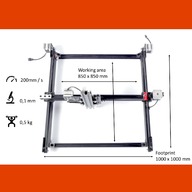

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Build Author

Ted Moyer

Views

5549

Build Author

Ted Moyer

Views

5549

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Build Author

Forestbird Originals

Views

5502

Build Author

Forestbird Originals

Views

5502

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

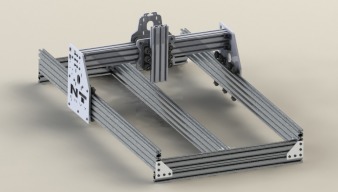

CNC NT

This is our first CNC project is based on OX CNC. We show you some pictures about our progress. We finished assembly design, software test and drivers test, now we are building the machine.

OnyX-13

This is my OX. There are many like it, but this one is mine. My OX is my best friend. It is my life. I must master it as I must master my life.....

Bessy 4x4

I found this to be a very fun exercise in building Bessy and will continue to improve her in the future.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

CNC PKB2

blueprints here: https://github.com/tomaspavlica/cnc_pkb2

ChadRat's ox

This is my first cnc router. I like the open builds concept. I bought parts when I had the money. It seems everytime i think i have all the parts, i find something I am missing. My controller won't be ready until the end of the month so I am in no hurry. I will add things that i find. Eager to make some saw dust.

Build Author

JerryD

Views

5353

Build Author

JerryD

Views

5353

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Custom OX Build

Inspired by the original OX by Mark Carew, this is my Custom OX. Many small changes, additions, and upgrades. Build is in progress and this post will be updated regularly with photos. Enjoy!

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

yakecadi

Views

5276

Build Author

yakecadi

Views

5276

All directions to innovate

all directions to innovate

Build Author

RobFromLDMS

Views

5275

Build Author

RobFromLDMS

Views

5275

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

McRouter 3 Axis CNC

I wanted to put together a medium size router using PTFE slides from McMaster-Carr. I've had great experience with these slides in long term continuous motion operations in industrial environments.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.