Build List

-

Active Filters:

cnc

Build Author

blterry1

Views

18817

Build Author

blterry1

Views

18817

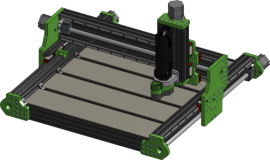

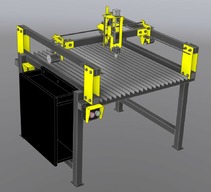

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

Build Author

alex_b

Views

18769

Build Author

alex_b

Views

18769

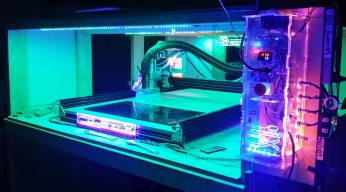

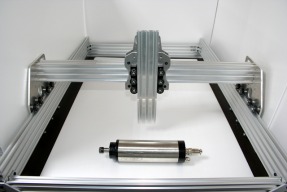

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Build Author

John J Talavera

Views

18598

Build Author

John J Talavera

Views

18598

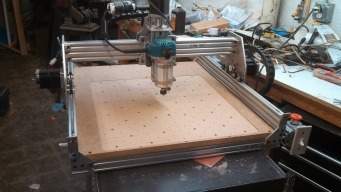

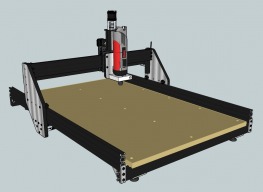

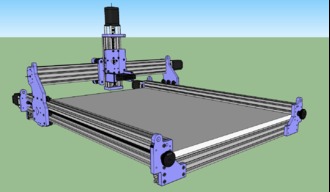

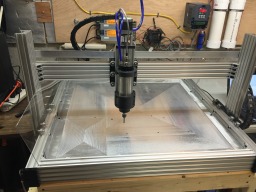

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Build Author

Savvas

Views

18576

Build Author

Savvas

Views

18576

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Build Author

viktop

Views

18309

Build Author

viktop

Views

18309

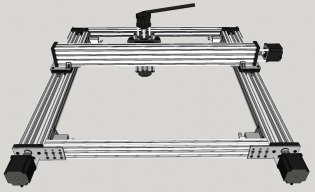

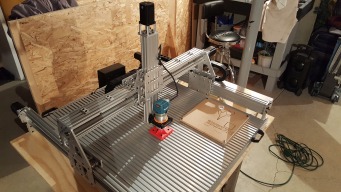

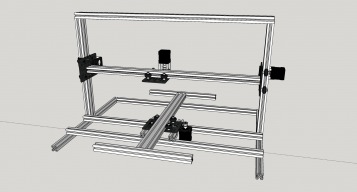

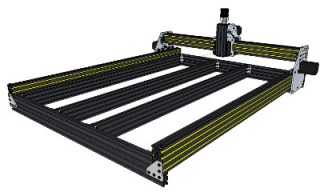

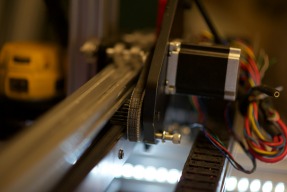

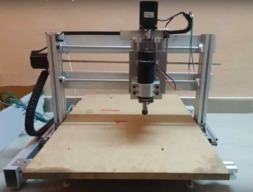

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

Glenn Weston

Views

18150

Build Author

Glenn Weston

Views

18150

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

CNC Router (Non OX)

My own Design (not an OX Derivative) using standard Parts.

Build Author

winand

Views

17933

Build Author

winand

Views

17933

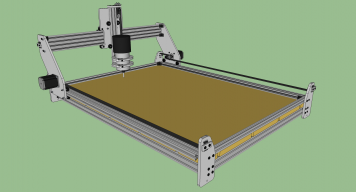

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

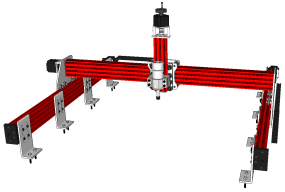

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

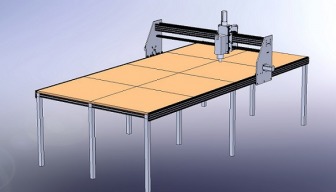

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

Andre Cooke

Views

17432

Build Author

Andre Cooke

Views

17432

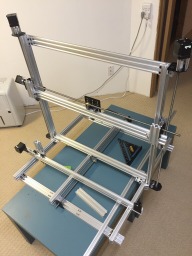

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Kermareg

Views

17271

Build Author

Kermareg

Views

17271

MOX CNC

[EN] Build of my Multiple OX CNC. It's goal is to run in 2 differents modes : router and 3D printer modes. The router mode will allows the use of a laser diode or a standard spindle. [FR] Construction d'une CNC basée sur l'OX pour des usages multiples. Deux modes principaux sont prévus : l'impression 3D et l'usinage via une defonceuses. Le mode usinage permettra à l'avenir de placerune tête laser pour effectuer quelques gravures simples. Une version française : http://kermareg.be/?page_id=103

The Buffalo

OX 1500 x 1000 mm

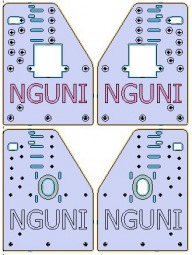

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

alex_b

Views

16951

Build Author

alex_b

Views

16951

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Build Author

SlyClockWerkz

Views

16823

Build Author

SlyClockWerkz

Views

16823

1000mm X 1500mm OX CNC -- Fiber/Garolite

Building the full size OX.

Build Author

rusirius

Views

16786

Build Author

rusirius

Views

16786

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

Build Author

Spark Concepts

Views

16439

Build Author

Spark Concepts

Views

16439

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

CharlieShimota

Views

16135

Build Author

CharlieShimota

Views

16135

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Build Author

brw_racing

Views

16103

Build Author

brw_racing

Views

16103

3d printed 2.5' X 2.5' cnc plasma cutting machine

Improvements to a cnc plasma cutter i designed a while back. Not that it really needs it to work but i think it could be an improvement.

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Aluminum OX build with some modifications

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!

Build Author

CubeSpawn

Views

15999

Build Author

CubeSpawn

Views

15999

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

Build Author

Teflon4

Views

15872

Build Author

Teflon4

Views

15872

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Screaming Ox CNC Machine

Big brother of the Charging Ox CNC machine.

Build Author

C-CNC

Views

15848

Build Author

C-CNC

Views

15848

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

ME - Laser CNC

Build of a small laser engraver using V-slot profiles and 3d printed parts

Build Author

Steve B

Views

15616

Build Author

Steve B

Views

15616

OX PPR - Portable Plasma/Router

PPR = Portable Plasma/Router. A ~30x30"work area with leadscrews. Work surface is below support members. Can be placed ONTO cutting surface.

Build Author

Damian V-SLOT Poland

Views

15516

Build Author

Damian V-SLOT Poland

Views

15516

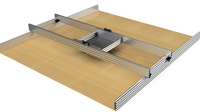

Router Sled V1.1 V-SLOT

We want to present you the new design of the device which is Router Sled. The whole structure is made of aluminum elements and ensures good quality of the device. We used V-SLOT aluminum profiles and OpenBuilds accessories for the construction. The instructional video can be found on our YouTube channel (subtitles in English soon)

spunks.cam

Design of a multifunctional CNC machine.

Build Author

Janis93

Views

15453

Build Author

Janis93

Views

15453

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

mytechno3d

Views

15322

Build Author

mytechno3d

Views

15322

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Build Author

Eric Jacobsson

Views

15245

Build Author

Eric Jacobsson

Views

15245

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

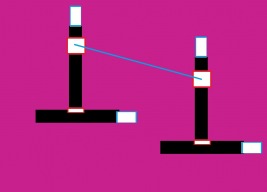

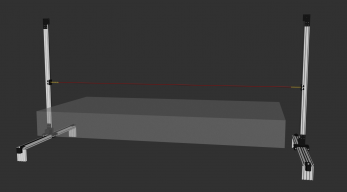

2 GANTRY CNC HOTWIRE MACHINE

A 2 independent gantry affordable hotwire machine.

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

AK-Creation

Views

14808

Build Author

AK-Creation

Views

14808

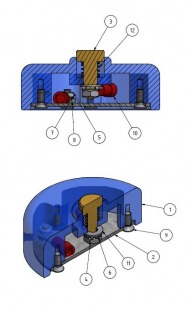

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Build Author

Mark Carew

Views

14718

Build Author

Mark Carew

Views

14718

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Build Author

David Arroyo

Views

14518

Build Author

David Arroyo

Views

14518

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Build Author

GinoTheCop

Views

14515

Build Author

GinoTheCop

Views

14515

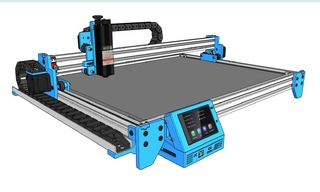

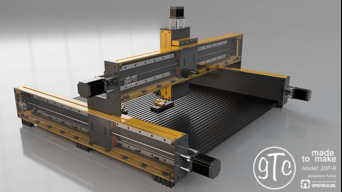

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

Build Author

Savvas

Views

14346

Build Author

Savvas

Views

14346

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

JWhitten

Views

14047

Build Author

JWhitten

Views

14047

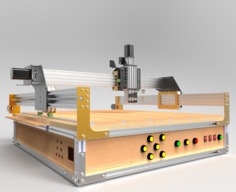

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

Ryan155

Views

13754

Build Author

Ryan155

Views

13754

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Build Author

Nugz

Views

13448

Build Author

Nugz

Views

13448

Angus : A Slightly "Beefier" OX

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.

Build Author

Joey Selzler

Views

13424

Build Author

Joey Selzler

Views

13424

My JGro CNC becomes an OpenBuild Project

This is the story of my progression from the JGRO cnc router design to using the OpenBuild system. In the process I think I have learned some things about cnc routers and the accuracy required to make a good build.

CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

My build is to allow me to cut foam wings using CNC Hot Wire Cutter.

Build Author

jpjoshua

Views

13092

Build Author

jpjoshua

Views

13092

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Build Author

signzonepr

Views

12975

Build Author

signzonepr

Views

12975

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Guitar shop CNC

Great bit of kit time will tell if it is up to the job

Build Author

chenderson

Views

12755

Build Author

chenderson

Views

12755

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

Build Author

ymilord

Views

12643

Build Author

ymilord

Views

12643

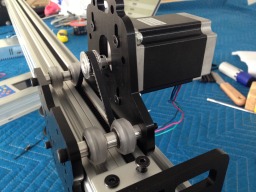

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

OX-Based Self-Contaned HVLP Spray Booth

A CNC HVLP spray booth based on OX.

Build Author

inhan

Views

12544

Build Author

inhan

Views

12544

OPENBUILDS Korea (ROVO 1000)

I am very grateful to Mark Carew with passion and imagination. Therefore, the machine is good, but making the website there too daedanhaeseo The end of the same either way to invisible homework. Thank you for allowing openbuilds team submitted to the challenge once again for those with a passion that I feel like in Korea, I want to be a great help.

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

![(R)OX CNC [FR/EN]](https://builds.openbuilds.com/data/article_images/l/1/1584.jpg?t=1423259127)

Build Author

AndersFaust

Views

12402

Build Author

AndersFaust

Views

12402

(R)OX CNC [FR/EN]

Another (R)OX CNC something like build, in French please ! Pics Heavy !

Build Author

GDanger117

Views

12217

Build Author

GDanger117

Views

12217

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Matt Nelson

Views

12190

Build Author

Matt Nelson

Views

12190

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

MaxBox

Simple cartesian style CNC. Uses ACME screws for all 3 axes, 20x40 v-slots and should have 50cm x 50cm x 50cm work volume.

Build Author

jamesdjadams

Views

12137

Build Author

jamesdjadams

Views

12137

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Build Author

pedrofernandez

Views

12112

Build Author

pedrofernandez

Views

12112

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

John J Talavera

Views

12099

Build Author

John J Talavera

Views

12099

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!

Build Author

Scott Martinez

Views

12042

Build Author

Scott Martinez

Views

12042

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

SandeepsCNC

Views

12040

Build Author

SandeepsCNC

Views

12040

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

Plasma Table 006

Fast, inexpensive, near-zero maintenance, and 2+ years of near-daily use.

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

Anthony Bolgar

Views

11937

Build Author

Anthony Bolgar

Views

11937

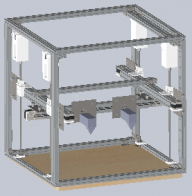

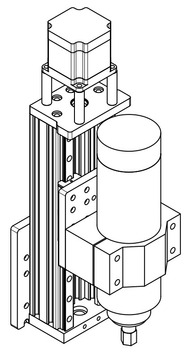

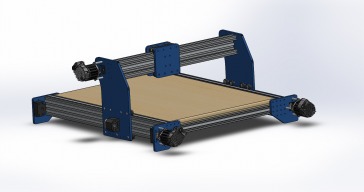

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Build Author

mirage335

Views

11898

Build Author

mirage335

Views

11898

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

Build Author

Andreas Bockert

Views

11835

Build Author

Andreas Bockert

Views

11835

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Big CNC plasma cutter

more later

Build Author

sw3Dp

Views

11732

Build Author

sw3Dp

Views

11732

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Longhorn OX (Under Construction and In Progress)

I ran across the OX and knew it was the one I wanted to build. Some of the things I wanted to include was make it bigger and a little more solid than what the original plans called for. So here is where I am at so far. It will have a cutting area of 48" x 48". The waste board support frame will have more support rails. The Y axis will have (3) 20mm x 60mm rails instead of the original (2) that is called for. 1/4" aluminum OX plates. And a few more odds and ends.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

that-jim

Views

11508

Build Author

that-jim

Views

11508

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

evil2002usna

Views

11485

Build Author

evil2002usna

Views

11485

Evil Ox

Cheap Ballscrew Ox CNC Router.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Build Author

David Florian

Views

11419

Build Author

David Florian

Views

11419

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Water Buffalo - Water jet cut OX+

A modified OX based on Aluminum plates cut on a waterjet. Some new ideas and additions from other builds are included.

Build Author

Yanou Fishel

Views

11202

Build Author

Yanou Fishel

Views

11202

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Ooznest OX CNC Build

Ooznest OX CNC build

CNC Hotwire Foam Cutter

Here is my first ever CNC build. A CNC Hotwire Foam Cutter. I will update about achievements. I would love to read from you guys - advices, ideas. Especially regarding the electronics. I feel confident with the hardware part which I can't say about the electronics part.

Build Author

Mike Campbell

Views

10995

Build Author

Mike Campbell

Views

10995

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Bear

Views

10972

Build Author

Bear

Views

10972

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Build Author

Steven Sampson

Views

10867

Build Author

Steven Sampson

Views

10867

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

Rob Taylor

Views

10753

Build Author

Rob Taylor

Views

10753

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.