Build List

-

Active Filters:

x

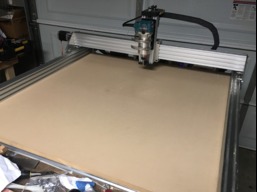

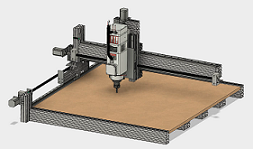

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

viktop

Views

18804

Build Author

viktop

Views

18804

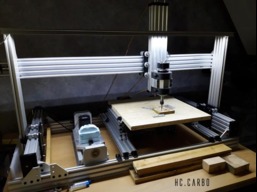

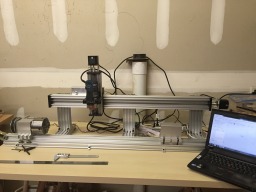

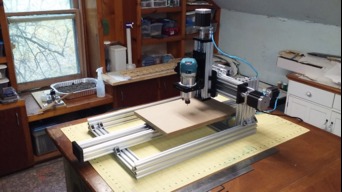

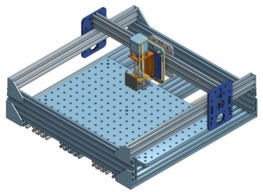

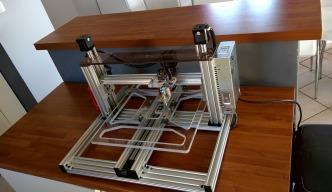

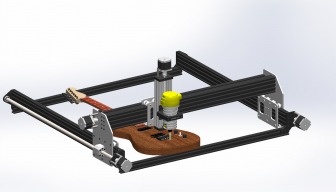

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

Sir Bagels

Views

3171

Build Author

Sir Bagels

Views

3171

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

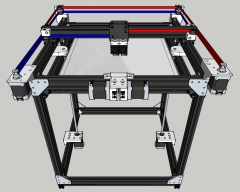

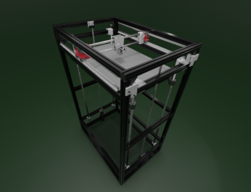

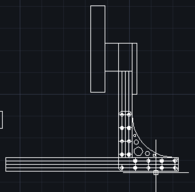

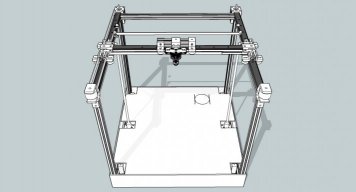

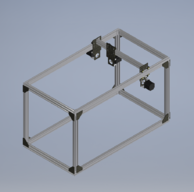

H-Bot CoreXY Cube

Dead build.

Build Author

Lasersc

Views

5535

Build Author

Lasersc

Views

5535

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Build Author

Keith Davis

Views

4118

Build Author

Keith Davis

Views

4118

Vulcan Bot

A 200mm x 300mm x 200mm workhorse that never needs leveling due to Posi-Drive Leveling design.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

roadss

Views

26151

Build Author

roadss

Views

26151

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

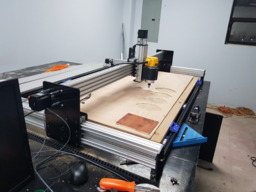

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

msdosfx

Views

6235

Build Author

msdosfx

Views

6235

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

Build Author

CoreCube3D

Views

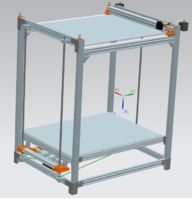

22260

Build Author

CoreCube3D

Views

22260

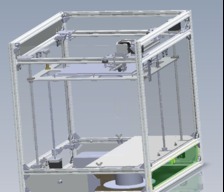

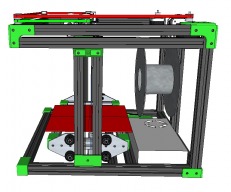

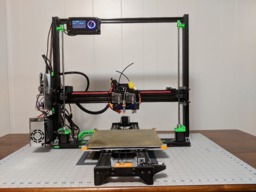

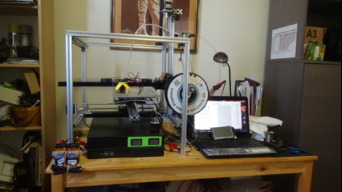

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

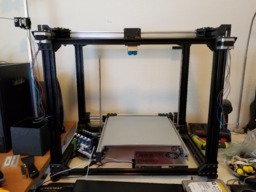

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Mushu - Large Scale CoreXY

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.

Build Author

Todd Brous

Views

5760

Build Author

Todd Brous

Views

5760

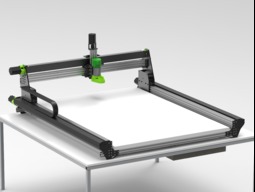

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

C Beam Rotary

I've used the good work of Openbuilds & expanded it to suit.

Build Author

RobFromLDMS

Views

5333

Build Author

RobFromLDMS

Views

5333

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Build Author

RV6APilot

Views

4268

Build Author

RV6APilot

Views

4268

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

Keith Davis

Views

20826

Build Author

Keith Davis

Views

20826

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Spark Concepts

Views

5490

Build Author

Spark Concepts

Views

5490

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Build Author

Ariel Yahni

Views

6710

Build Author

Ariel Yahni

Views

6710

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

Butterfly 3DP V 1.0

tronxy x3 like

Build Author

Vegard Humlen

Views

5097

Build Author

Vegard Humlen

Views

5097

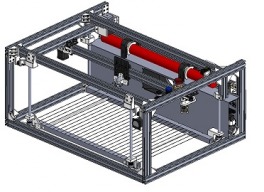

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Build Author

Christian James

Views

10143

Build Author

Christian James

Views

10143

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Big a** printer

In-progress 500x500x1800

Build Author

joetemus

Views

6946

Build Author

joetemus

Views

6946

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

Lumberjack Engineering

Views

20283

Build Author

Lumberjack Engineering

Views

20283

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Router for speargun hobby

First router build for speargun fabrication

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Build Author

MrMojoRisin

Views

7660

Build Author

MrMojoRisin

Views

7660

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Build Author

Savvas

Views

18911

Build Author

Savvas

Views

18911

CNC Control Box with VFD etc etc

I'm currently working on the CNC control box, before doing any future work on the CNC Mountain Machine. I want the controller to be future proof and as professional as I can manage. I am planning to use stepper drivers, PSU's, a motor contactor unit to turn everything on, as well as a VFD and proximity limits switches. Each video will document the process and steps involved in researching, designing, planning and assembling a controller. I am not a natural electrician so learning as I go.

Build Author

Rob Mahan

Views

13965

Build Author

Rob Mahan

Views

13965

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

CNC by MagicMarcus

CNC variation about Sphinx.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

ChrisViral

Views

7219

Build Author

ChrisViral

Views

7219

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

rob4cnc

Views

4057

Build Author

rob4cnc

Views

4057

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Robert E. Nee

Views

17713

Build Author

Robert E. Nee

Views

17713

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Build Author

James Evanko

Views

4909

Build Author

James Evanko

Views

4909

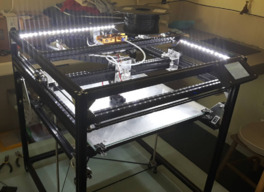

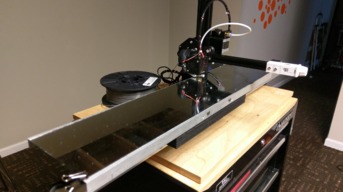

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Build Author

Rick Holder

Views

15492

Build Author

Rick Holder

Views

15492

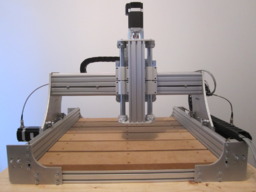

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

Luke Cunningham

Views

5942

Build Author

Luke Cunningham

Views

5942

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

SCYBUCK

Views

5165

Build Author

SCYBUCK

Views

5165

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Michael.M

Views

9766

Build Author

Michael.M

Views

9766

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

MikieLikesIt

Views

8298

Build Author

MikieLikesIt

Views

8298

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

Kevr102

Views

5903

Build Author

Kevr102

Views

5903

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Build Author

mytechno3d

Views

28585

Build Author

mytechno3d

Views

28585

Maximus Evolution (Still another XL 3D Printer )

Maximus Evolution : 380mm x 400mm XL 3D Printer

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Build Author

Nicademus

Views

9676

Build Author

Nicademus

Views

9676

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Carl Siren

Views

7706

Build Author

Carl Siren

Views

7706

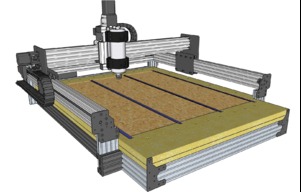

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

thehans

Views

6733

Build Author

thehans

Views

6733

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

pedrofernandez

Views

12249

Build Author

pedrofernandez

Views

12249

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Mark Rehorst

Views

10256

Build Author

Mark Rehorst

Views

10256

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Glenn Weston

Views

18408

Build Author

Glenn Weston

Views

18408

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

Colin Russon

Views

9493

Build Author

Colin Russon

Views

9493

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

BinaryConstruct

Views

10292

Build Author

BinaryConstruct

Views

10292

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Gary Caruso

Views

25010

Build Author

Gary Caruso

Views

25010

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Sword66

Views

14087

Build Author

Sword66

Views

14087

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

Build Author

Julius

Views

25567

Build Author

Julius

Views

25567

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

2779

Build Author

Sprags

Views

2779

C-Beam Kyo Sphinx 10060

More stuff here.

DPR-v2 full metal

pictures and mony doku see later

Big-X Minimill

Minimill bundle, but with an extended X Axis

Build Author

TurfnSurf

Views

6258

Build Author

TurfnSurf

Views

6258

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

Keith Davis

Views

5497

Build Author

Keith Davis

Views

5497

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Build Author

Hussein Dermay

Views

6598

Build Author

Hussein Dermay

Views

6598

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

Axnfell

Views

3148

Build Author

Axnfell

Views

3148

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

pedrofernandez

Views

7985

Build Author

pedrofernandez

Views

7985

ACRO 20x20

The Acro Laser Machine Build

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Build Author

h3rb

Views

5840

Build Author

h3rb

Views

5840

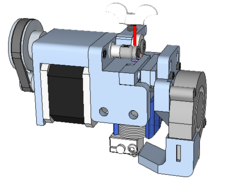

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Naomi Wu

Views

10919

Build Author

Naomi Wu

Views

10919

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

Weldsmith

Views

7802

Build Author

Weldsmith

Views

7802

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Build Author

TimVukman

Views

4345

Build Author

TimVukman

Views

4345

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

Blyn3D

Views

6480

Build Author

Blyn3D

Views

6480

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

Bucky Wootmaster

Views

3045

Build Author

Bucky Wootmaster

Views

3045

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

crnrstndes

Views

4289

Build Author

crnrstndes

Views

4289

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!