Build List

-

Active Filters:

nt

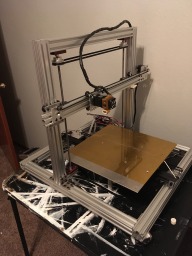

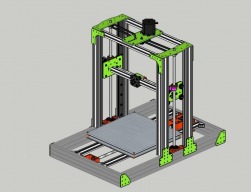

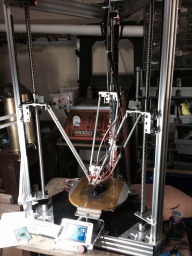

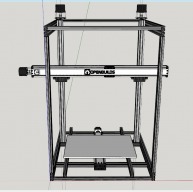

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Build Author

Martin Bogomolni

Views

12402

Build Author

Martin Bogomolni

Views

12402

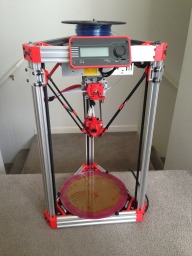

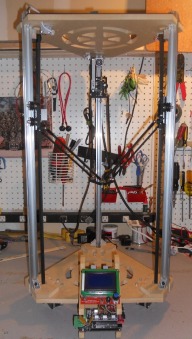

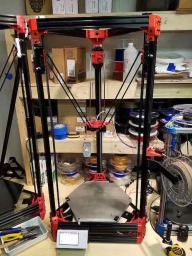

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

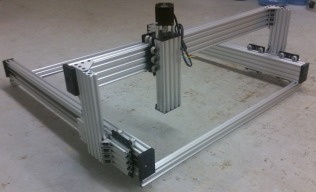

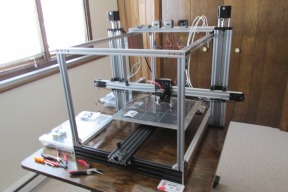

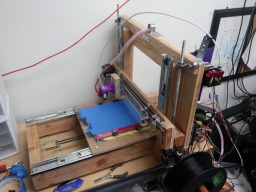

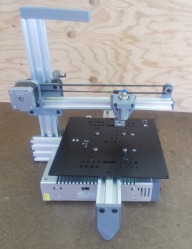

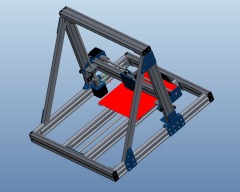

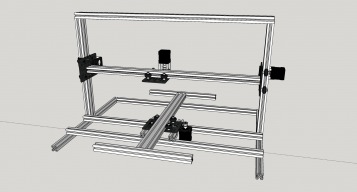

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

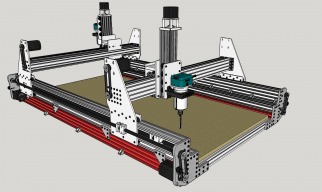

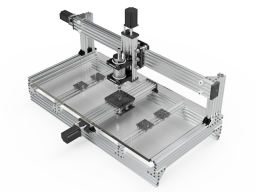

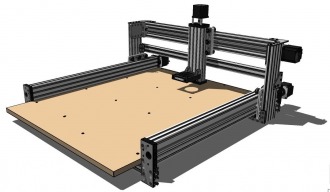

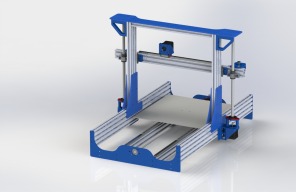

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

THE LINK

Views

5140

Build Author

THE LINK

Views

5140

2020 First build.

Probably cheapest DIY build youl see.

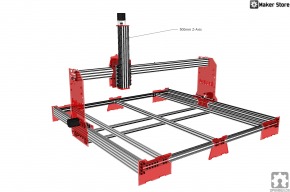

Voxel OX Based Build

Building upon the great work done by Marshall Peck and others. I have started a new build.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Delta-Six

Super rigid Delta printer, using 20X40 V-Slot

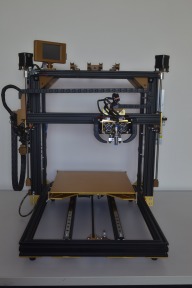

Steel Frame 3D Printer

A steel framed 3D printer using a similar design with my CNC Router.

Build Author

sgspenceley

Views

9145

Build Author

sgspenceley

Views

9145

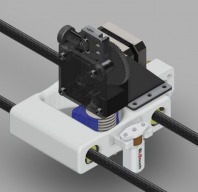

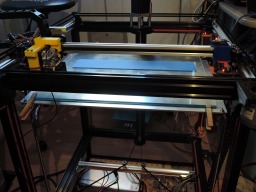

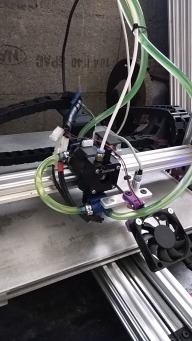

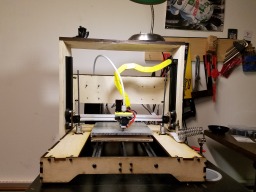

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

Build Author

Venturebit

Views

13989

Build Author

Venturebit

Views

13989

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

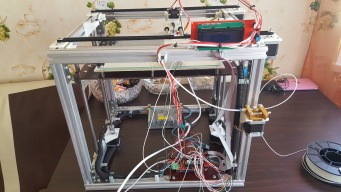

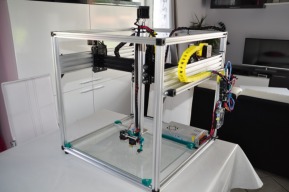

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

Kool Bot

Mid range build.

Build Author

evgeny156

Views

7389

Build Author

evgeny156

Views

7389

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Limine3D

Views

8657

Build Author

Limine3D

Views

8657

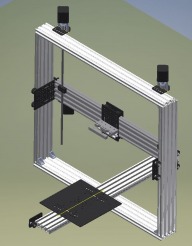

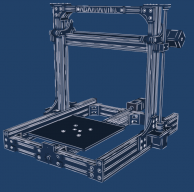

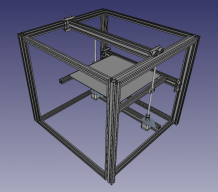

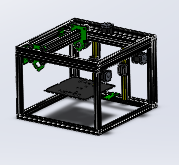

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Build Author

Anglesachse

Views

29249

Build Author

Anglesachse

Views

29249

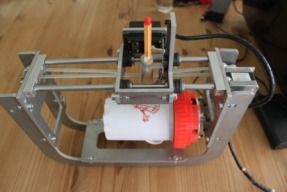

Pot Plotter

My version of the Mug Plotter designed by Teed http://edinburghhacklab.com/ . Also used the Eibotboard from the original eggbot from evilmadscientists http://shop.evilmadscientist.com/partsmenu/188-ebb A huge thanks to Hexitex for his brilliant Four jaw chuck http://www.thingiverse.com/thing:5791

Build Author

mikev

Views

8670

Build Author

mikev

Views

8670

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Tomas F Uribe

Views

5393

Build Author

Tomas F Uribe

Views

5393

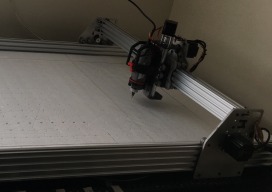

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

J-Wahl Dezign

Views

9202

Build Author

J-Wahl Dezign

Views

9202

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

eddyg

Views

5054

Build Author

eddyg

Views

5054

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

Build Author

nschreiber0813

Views

5556

Build Author

nschreiber0813

Views

5556

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

Build Author

adamcooks

Views

43479

Build Author

adamcooks

Views

43479

Triple C-Bot

Based on the work of Carl Feniak and his C-Bot. A robust Core XY style 3D printer that has a clean parallel belt implementation and whose dimensions are adaptable to meet builder's needs. The use of open builds V-slot and other open hardware make customization easy. Utilizing a 300x300 build plate this derivation utilizes three lead screws, synced to a single motor via gt2 belt

Build Author

Jonathon Duerig

Views

7274

Build Author

Jonathon Duerig

Views

7274

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

Limine3D

Views

21898

Build Author

Limine3D

Views

21898

M3Delta

Delta printer designed in sketchup and includes an adjustable bed.

Build Author

3D Meister

Views

5615

Build Author

3D Meister

Views

5615

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

Robert Huxford

Views

4079

Build Author

Robert Huxford

Views

4079

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

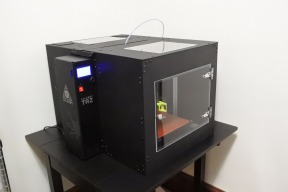

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

Build Author

Anthony Bolgar

Views

12153

Build Author

Anthony Bolgar

Views

12153

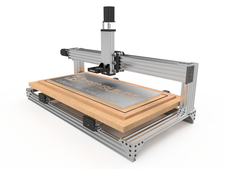

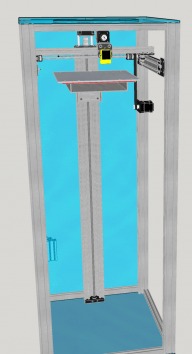

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

My 1st Build - Delta Printer with 3 filament hot end

The build area will be fully enclosed. I anticipate using primarily ABS, and have interest in the soluble support materials as well. The main components to date include: OPENBUILDS - 3 x C-Beam™ Linear Actuator Bundle, 1000 mm, w/ Included NEMA23 Motor) Extruders (3) - [Sintron] 1.75mm Mini All Metal MK8 Extruder Hot End - reprap diamond Control board - RUMBA Stepper drivers - DRV8825 StepStick Power supply - eTopxizu 12v 30a

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

BAFP 3D Printer

A New Core XY Printer build. BAFP stands for Big And Fast Printer. It will be awesome !!

delta 3d printer kit

HE3D K200 kit build

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

Build Author

Linkreincarnate

Views

3181

Build Author

Linkreincarnate

Views

3181

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

Build Author

TouchPadKing

Views

5150

Build Author

TouchPadKing

Views

5150

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

dodgenet

Views

6661

Build Author

dodgenet

Views

6661

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

Hytech2k

Views

34041

Build Author

Hytech2k

Views

34041

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

Build Author

Ken376

Views

3797

Build Author

Ken376

Views

3797

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Build Author

Joe Garritano

Views

11805

Build Author

Joe Garritano

Views

11805

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

Build Author

Jose A. Molina

Views

7089

Build Author

Jose A. Molina

Views

7089

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Power Playground

Views

4908

Build Author

Power Playground

Views

4908

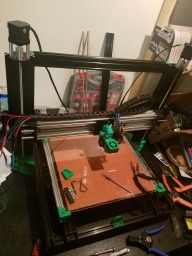

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

Build Author

Philippe Bergeron

Views

10179

Build Author

Philippe Bergeron

Views

10179

My first 3D printer: Absolute3Dr

You are about to read the evolution of my 3d Printer build.

Build Author

Mark Carew

Views

75113

Build Author

Mark Carew

Views

75113

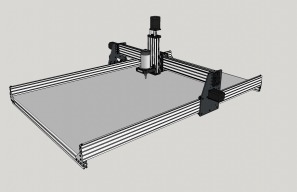

X Y Table OpenRail / V-Slot Build Examples

The X/Y table system is a great starting point for many CNC projects giving you the ability to move an object on the X and Y axis in a simple compact style.

Build Author

mytechno3d

Views

66383

Build Author

mytechno3d

Views

66383

Maximus 3D Printer

A full scalable 3D Printer , with a big printing area. Build with openbuild parts from www.vslot-europe.com

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

Kaarbble

Views

10443

Build Author

Kaarbble

Views

10443

Kaarbble Nylon Bot

We plan experiment on nylon 3 D printing;

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Build Author

AK-Creation

Views

15057

Build Author

AK-Creation

Views

15057

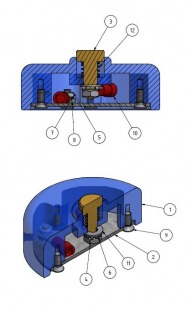

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Build Author

sw3Dp

Views

11969

Build Author

sw3Dp

Views

11969

stranger than fiction OX

OX hybrid all CAD open sourced non-commercial ip; .dwg, .dxf,.3dm, .iam, .ipt files jamming their pie

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

Build Author

Krishnakumar

Views

8879

Build Author

Krishnakumar

Views

8879

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Adamantine

This is Adamantine, a all aluminum lead screw driven 3d printer. I wanted to have a printer that would not be effected by the heat or humidity I have here as my current wood frame printer is.

Build Author

Asaku

Views

9730

Build Author

Asaku

Views

9730

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

dddman

Views

13721

Build Author

dddman

Views

13721

Prusa i3 (Acrylic frame with OB rods)

The Prusa i3 (iteration 3) is the newest and most current 3D Printer design by RepRap Core Developer Prusajr (source: http://reprap.org/wiki/Prusa_i3)

V-slot and MDF DeltaBot

This is a deltabot 3D printer build using CNC routed MDF and v-slot rails. Full description found in instructables.com.

SimplrBot

This is a simple, yet rugged design, weighing only 6 lbs and with 13x13x14" volume with a 8x8x6" build area. While assembly is pretty simple, the small size and rigidity of the design make shipping assembled printers attractive.

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

M^3

Views

17771

Build Author

M^3

Views

17771

M Cubed 3 Axis Bluetooth CNC Controller

Low cost, Bluetooth enabled, 3 axis CNC controller. GRBL 0.9 compatible.

Build Author

Peter Oakes

Views

44464

Build Author

Peter Oakes

Views

44464

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

griso

Views

9381

Build Author

griso

Views

9381

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

UltiBots

Views

10613

Build Author

UltiBots

Views

10613

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Infinite Z Delta Printer

Currently completely imaginary

Update for my 3D Printer - Big Size

I like combo machines, so I upgrade my 3D Printer with a Laser. It is a double head combination. The Laser is easy removable.

Build Author

Rwetzler

Views

9500

Build Author

Rwetzler

Views

9500

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

Build Author

Sheepdog

Views

26933

Build Author

Sheepdog

Views

26933

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

V Rail 3D printer

My version a Cartesian style 3d printer, an attempt to eliminate frame vibration and movement and to use up materials left over from other projects.

Build Author

Jesse Jenkins

Views

9482

Build Author

Jesse Jenkins

Views

9482

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Bobnet

Views

13414

Build Author

Bobnet

Views

13414

Rackmount + OpenRail

OpenRail attached to a 19" rackmount 15U box.

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Pelican Case 3D Printer

A portable 3D Printer that can flat pack into a hard carry case

Build Author

andrizzle

Views

7069

Build Author

andrizzle

Views

7069

Printer1

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

Build Author

cbordeleau

Views

13351

Build Author

cbordeleau

Views

13351

OpenBuilds C-Beam Double Slider

This slider uses an 500mm OpenBuilds C-beam and the design is such that the effective length of the slider is slightly less then twice the length of the C-Beam. It can be used both motorized or not.

Build Author

rusirius

Views

17007

Build Author

rusirius

Views

17007

MultiBOT LRP

A CNC platform designed with swapable heads to do laser engraving/etching/cutting, routing and milling, as well as 3D printing.

Build Author

cbordeleau

Views

6155

Build Author

cbordeleau

Views

6155

Slider Levelling Platform

3d printed V-Slot Gantry Plate leveler.

MakerSL MSL-6 DLP 3D Printer

This will be a DLP 3D Printer designed around an Openbuilds Frame and rail system. It will be a collaborated effort between myself and Ben Smith. We will be building two prototypes.

Build Author

Sonny Lowe

Views

10926

Build Author

Sonny Lowe

Views

10926

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

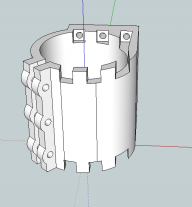

20x60 to Dewalt 611 Mount (a.k.a the Rook)

Dewalt 611 Router mount for mounting onto 20x60 v-slot

Delta 3D Printer

This is a Delta build using 1610 ballscrews from China

Versabot - All metal 3D printer

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

Build Author

The Dude

Views

22241

Build Author

The Dude

Views

22241

Optical Limit + Home Switches

Optical home and limit switches for cnc, 3D printers, laser cutters, etc.

Build Author

Cbrown330

Views

5450

Build Author

Cbrown330

Views

5450

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

C-Beam for lithophanes

First venture into cnc machining I decided on the C-Beam .

Build Author

David Arroyo

Views

14794

Build Author

David Arroyo

Views

14794

PiDuinoCNC Controller

Using a Raspberry Pi, Arduino and a Protoneer CNC Shield to create an Open Source CNC router controller. It will be equipped with a touch screen to control the on board processor. The touch screen will run a user interface that has buttons for added functionality. There will be a camera for monitoring progress from inside my office. The control box will also feature a way to power the vacuum and spindle/router . I will also be able to monitor room temp as well as Pi CPU temps and averages.

Build Author

Mike Andrews

Views

9373

Build Author

Mike Andrews

Views

9373

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Build Author

Nwrgordon

Views

15977

Build Author

Nwrgordon

Views

15977

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com