Build List

-

Active Filters:

h

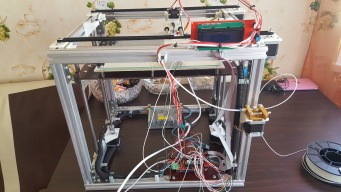

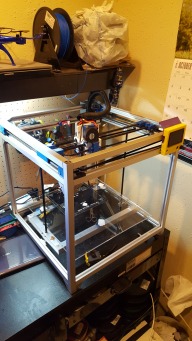

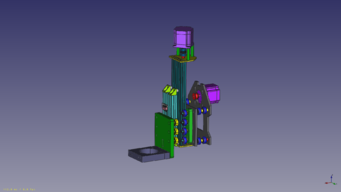

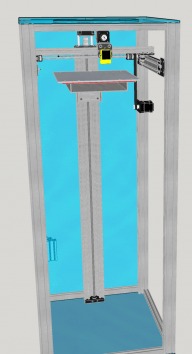

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

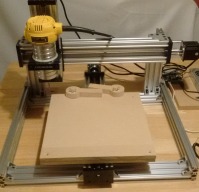

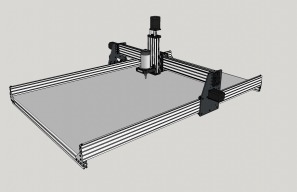

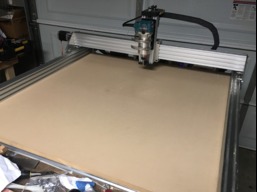

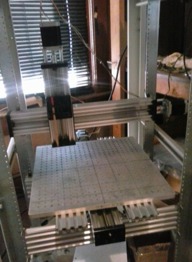

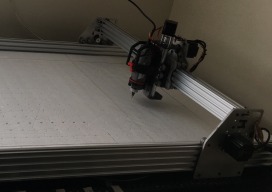

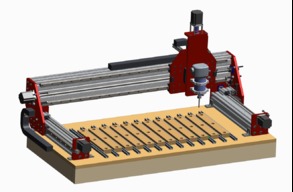

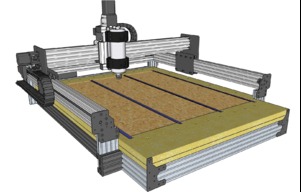

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

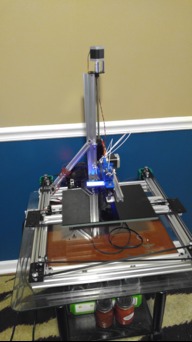

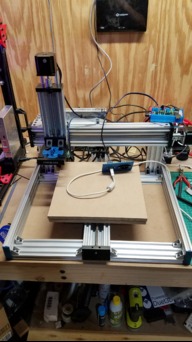

laser add-on for C-Beam machine

3.8 W laser add-on for C-Beam machine. Can easily be swapped with the router.

Build Author

Metalguru

Views

14631

Build Author

Metalguru

Views

14631

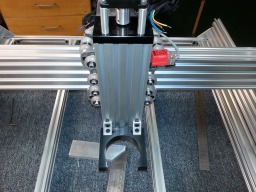

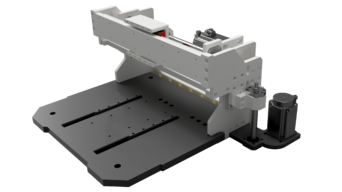

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

Rwetzler

Views

9341

Build Author

Rwetzler

Views

9341

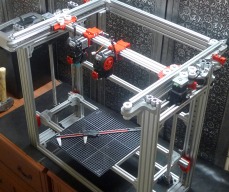

C-Beam Prototype

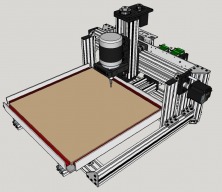

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

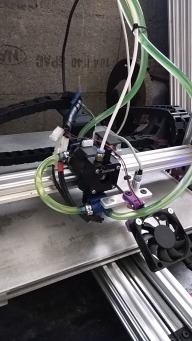

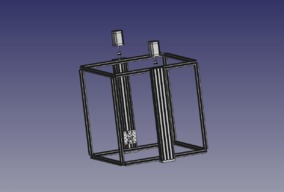

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

Build Author

William Niedermeyer

Views

19585

Build Author

William Niedermeyer

Views

19585

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

Build Author

Jose A. Molina

Views

6982

Build Author

Jose A. Molina

Views

6982

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Simon Rafferty

Views

7546

Build Author

Simon Rafferty

Views

7546

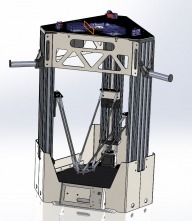

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

Build Author

Krishnakumar

Views

8696

Build Author

Krishnakumar

Views

8696

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

MOJO 3D

Fast, Large build area, CoreXY design

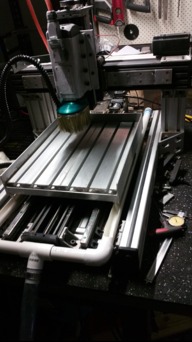

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Build Author

Edgar Robles

Views

4084

Build Author

Edgar Robles

Views

4084

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

delta 3d printer kit

HE3D K200 kit build

Build Author

Ken376

Views

3727

Build Author

Ken376

Views

3727

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

JP Warnke

Views

12795

Build Author

JP Warnke

Views

12795

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

dodgenet

Views

6576

Build Author

dodgenet

Views

6576

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Build Author

Thair.nl

Views

3795

Build Author

Thair.nl

Views

3795

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Build Author

taratata2016

Views

8564

Build Author

taratata2016

Views

8564

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8537

Build Author

Limine3D

Views

8537

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Wifi'not

A simple made hideaway for ugly electronics

Build Author

Makerparts

Views

7680

Build Author

Makerparts

Views

7680

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Build Author

Chetan PM

Views

3804

Build Author

Chetan PM

Views

3804

Composer

Gantry style rigid build

Build Author

Robert Huxford

Views

3961

Build Author

Robert Huxford

Views

3961

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

J-Wahl Dezign

Views

9129

Build Author

J-Wahl Dezign

Views

9129

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

3D Meister

Views

5487

Build Author

3D Meister

Views

5487

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

recoush

Views

9228

Build Author

recoush

Views

9228

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

nschreiber0813

Views

5465

Build Author

nschreiber0813

Views

5465

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

Build Author

THE LINK

Views

5065

Build Author

THE LINK

Views

5065

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Tomas F Uribe

Views

5323

Build Author

Tomas F Uribe

Views

5323

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Build Author

Hisha

Views

5014

Build Author

Hisha

Views

5014

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

Huub65

Views

9237

Build Author

Huub65

Views

9237

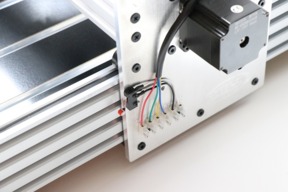

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

evgeny156

Views

7315

Build Author

evgeny156

Views

7315

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Jens Grabner

Views

4106

Build Author

Jens Grabner

Views

4106

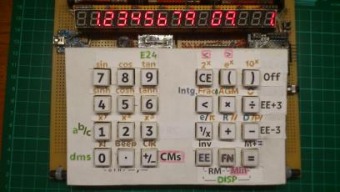

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

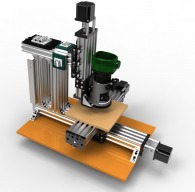

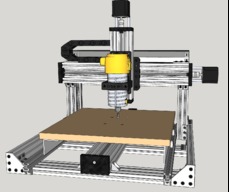

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

Fabio Orsi

Views

6927

Build Author

Fabio Orsi

Views

6927

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Build Author

megashub

Views

24199

Build Author

megashub

Views

24199

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Karan Singh Sisodia

Views

6282

Build Author

Karan Singh Sisodia

Views

6282

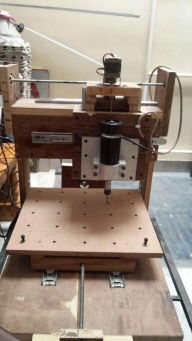

My Home made CNC

Home Made CNC Router from Scrape

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Build Author

JerryD

Views

5321

Build Author

JerryD

Views

5321

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Build Author

SecretSpy711

Views

22505

Build Author

SecretSpy711

Views

22505

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Anthony Castelluci

Views

3227

Build Author

Anthony Castelluci

Views

3227

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

Tucstrlly

Views

9046

Build Author

Tucstrlly

Views

9046

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

Build Author

Kyo

Views

10052

Build Author

Kyo

Views

10052

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Build Author

patdee

Views

5092

Build Author

patdee

Views

5092

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

pedrofernandez

Views

12147

Build Author

pedrofernandez

Views

12147

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Dave Pyatt

Views

4496

Build Author

Dave Pyatt

Views

4496

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2815

Build Author

Terone Burgenheim

Views

2815

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6425

Build Author

Terone Burgenheim

Views

6425

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8376

Build Author

Carl van Heezik

Views

8376

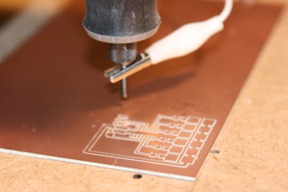

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Nicademus

Views

9527

Build Author

Nicademus

Views

9527

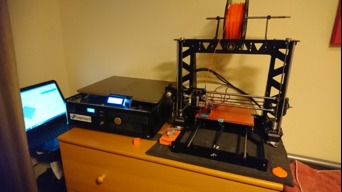

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Connor Mckeown

Views

6383

Build Author

Connor Mckeown

Views

6383

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

bpatterson42

Views

3549

Build Author

bpatterson42

Views

3549

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

Daniel.korneliussen

Views

3480

Build Author

Daniel.korneliussen

Views

3480

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

spark2

Views

5669

Build Author

spark2

Views

5669

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Sprags

Views

2725

Build Author

Sprags

Views

2725

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Glenn Weston

Views

11391

Build Author

Glenn Weston

Views

11391

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

Blyn3D

Views

6368

Build Author

Blyn3D

Views

6368

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

h3rb

Views

3726

Build Author

h3rb

Views

3726

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

obmilllivebuild

Views

5624

Build Author

obmilllivebuild

Views

5624

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

Limine3D

Views

4504

Build Author

Limine3D

Views

4504

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

Hussein Dermay

Views

6470

Build Author

Hussein Dermay

Views

6470

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Build Author

Brandon Satterfield

Views

7695

Build Author

Brandon Satterfield

Views

7695

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Build Author

jpjoshua

Views

13322

Build Author

jpjoshua

Views

13322

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7120

Build Author

ChrisViral

Views

7120

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.