Build List

-

Active Filters:

x

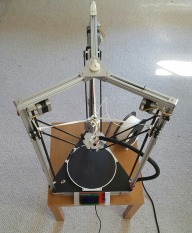

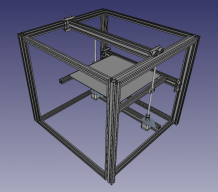

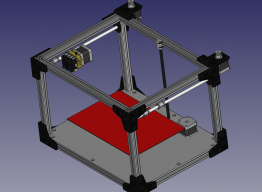

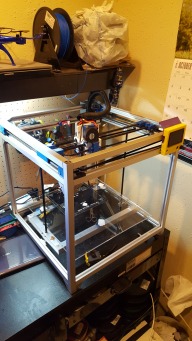

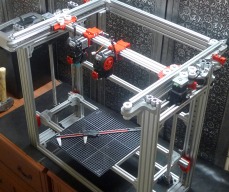

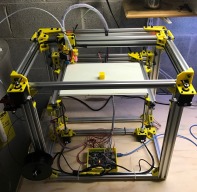

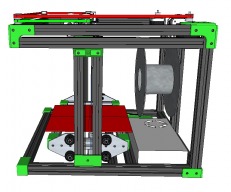

Delta Bot: Improved DIY 3D Printer

Build the efficient and reliable all metal structure 3D Printer. Improved significantly with new concepts for printers. Great quality and up to 400 mm/s print speed (very fast). Built with heated bed, hybrid bowden suspended extruder, and counterweight (tested printing 21 hours straight with no motors hot). Optional smart controller for computerless printing. Print any kind of thermoplastic.

Build Author

Skoobs

Views

4954

Build Author

Skoobs

Views

4954

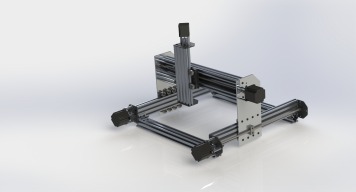

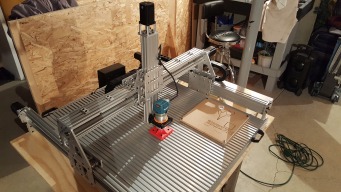

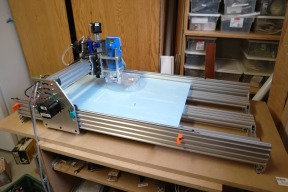

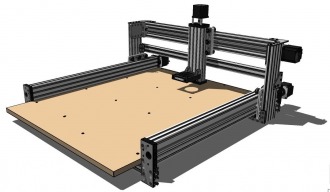

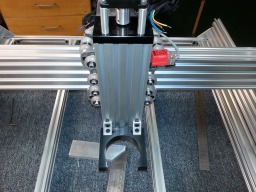

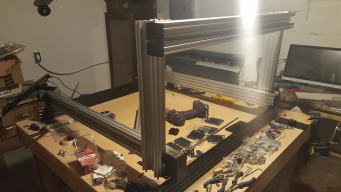

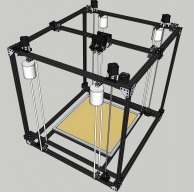

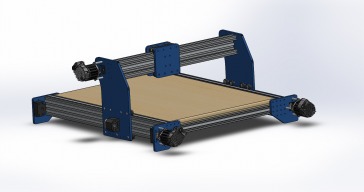

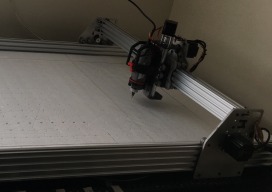

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Build Author

Steven Sampson

Views

10934

Build Author

Steven Sampson

Views

10934

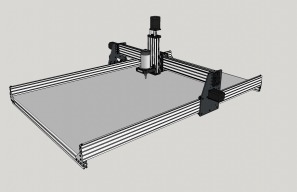

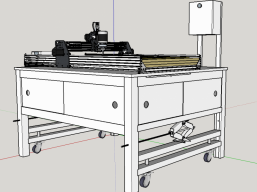

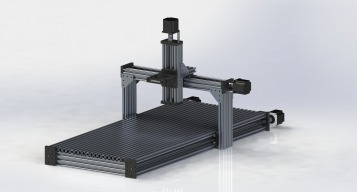

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

Keith Davis

Views

20703

Build Author

Keith Davis

Views

20703

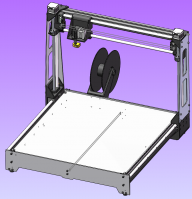

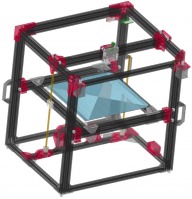

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

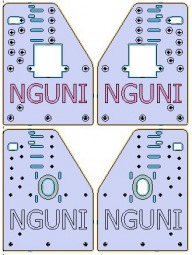

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

core xy smoothie

i had som left over parts and i dit like to test the corexy control so this is wat i came up with. sorry bad englich.

C-Beam Router, 48"x48"

C-Beam Router using 1500mm lengths, 48x48" build area, and rack and pinion movement.

Build Author

evildean

Views

8902

Build Author

evildean

Views

8902

OX-SUMO, SUMO-OX, OXSUMO?

One meter square. Short and stout.... reminds me of a Sumo Wrestler. A temporary and adjustable configuration I have devised to cut my own plates. I have kicked around ideas for about a year and the C-Beam extrusion has made this attempt to realize my ideas irresistible. This is just one step towards bigger and better things!

Build Author

Peter Oakes

Views

44289

Build Author

Peter Oakes

Views

44289

The Bull Dog, A RoverCNC OX based 1500mm x 1500mm CNC - Tutorial build

I have based this build on the OX build so I will not be going into too much detail of specefic assembly modules as they asre so well covered by Mark Carew already, but will go through the complete build on video. I will be addig additional tutorials on steppers and the other electronic parts as needed though as this project is sponsored by RS Components in the form of most of the Electronics and this is also the key focus of my YouTube channel www.youtube.com/c/thebreadboardca.

Build Author

Fabio Bertuzz

Views

4253

Build Author

Fabio Bertuzz

Views

4253

DutziDelta RepStrap

Fascinated for some time by 3D Printing. Now, after studying countless forum posts, blogs and similiar stuff, i want to Start with my own build. Maybe a bit much but usually i thrive with the challenge.

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

XYZ Factory Bot

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

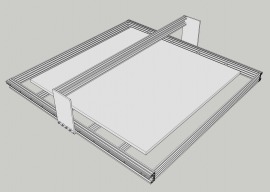

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

OX 1000mm Y Axis Upgrade

Expands y-axis to 1000mm. 1/2 day build.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

Build Author

Steve Marsh

Views

5763

Build Author

Steve Marsh

Views

5763

Dust Shoe for Colt router and OxCarve

A simple 3D printed dust shoe for the cnc router. 2 parts held together with magnets for easy bit changes.

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

Build Author

zann68

Views

9310

Build Author

zann68

Views

9310

OX CNC 4'x4'

Out with the Old in with the New. Trying to build a nice clean setup that myself and my sons can use and enjoy.

Build Author

Gary Bonard

Views

6186

Build Author

Gary Bonard

Views

6186

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

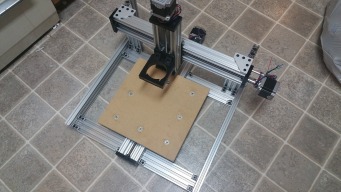

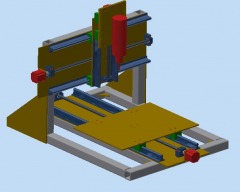

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Build Author

Nwrgordon

Views

15905

Build Author

Nwrgordon

Views

15905

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Builder Bob's CNC

Here is the consolidation of my woodworking shop, a CNC Router!

Build Author

Cbrown330

Views

5391

Build Author

Cbrown330

Views

5391

Big 3d Printer, Big Brown

This is a big 609 x 609 x 914 3d pritner with exchangable hot ends and extruders.

Build Author

Colin Russon

Views

9432

Build Author

Colin Russon

Views

9432

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

evil2002usna

Views

11571

Build Author

evil2002usna

Views

11571

Evil Ox

Cheap Ballscrew Ox CNC Router.

1500 x 1500 mm OpenBuild CNC

1500 x 1500 mm OpenBuild CNC

Ooznest build - 1500mm x 1000mm

Its the first build for me so its just the story of me attempting to build the kit and hopefully end up with something I can use. Hopefully without destroying anything or anyone.

Build Author

Paruk

Views

23156

Build Author

Paruk

Views

23156

Buffal-O-Tron

A 3D Scanning Station

OX Super "C" - Cpmpleted 11/02/16

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

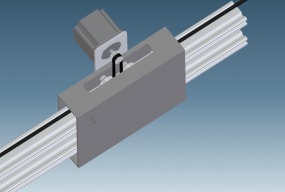

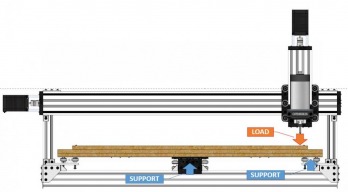

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

Large OX

A larger version of the OX.

Build Author

Keteland

Views

10712

Build Author

Keteland

Views

10712

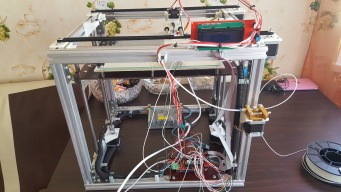

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

Matt Nelson

Views

12320

Build Author

Matt Nelson

Views

12320

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

Anthony Bolgar

Views

12050

Build Author

Anthony Bolgar

Views

12050

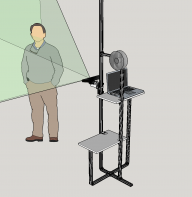

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

eddyg

Views

5001

Build Author

eddyg

Views

5001

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

Build Author

Rwetzler

Views

9384

Build Author

Rwetzler

Views

9384

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

4-axis C-Beam Hot Wire Wing cutter

4-axis CNC Hot wire foam wing cutter

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Custom Ox

Custom black and red Big Ox

Build Author

Dave420

Views

14525

Build Author

Dave420

Views

14525

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Schematix OX metal build

OX metal build from an noob

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Build Author

Krishnakumar

Views

8743

Build Author

Krishnakumar

Views

8743

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

MOJO 3D

Fast, Large build area, CoreXY design

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Pure Cbeam 900x1000

This is a pure cbeam build to maximize envelope and rigidity. All the parts used are available from open builds.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

Build Author

Edgar Robles

Views

4100

Build Author

Edgar Robles

Views

4100

Sheethexapod

Sheethexapod works with basic mechanims as direct metal-metal links and joints, all movements can be done by a rc servomotor in this case towerpro model.

Build Author

Power Playground

Views

4847

Build Author

Power Playground

Views

4847

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Slightly larger sphinx

Another C-Beam Sphinx but a little larger,

Build Author

dodgenet

Views

6604

Build Author

dodgenet

Views

6604

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

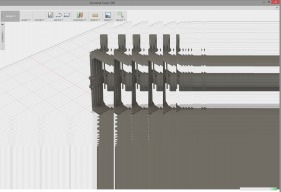

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Wifi'not

A simple made hideaway for ugly electronics

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Greg Lampman

Views

9230

Build Author

Greg Lampman

Views

9230

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Tom Dirriwachter

Views

7372

Build Author

Tom Dirriwachter

Views

7372

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Build Author

Dmknerr

Views

5224

Build Author

Dmknerr

Views

5224

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

A work in progress

One of my first projects might be cutting proper plates.

Build Author

McAdam

Views

3742

Build Author

McAdam

Views

3742

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

Robert Huxford

Views

3999

Build Author

Robert Huxford

Views

3999

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7518

Build Author

Matt Barile

Views

7518

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

J-Wahl Dezign

Views

9147

Build Author

J-Wahl Dezign

Views

9147

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

3D Meister

Views

5525

Build Author

3D Meister

Views

5525

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

Build Author

Robert E. Nee

Views

17491

Build Author

Robert E. Nee

Views

17491

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

recoush

Views

9293

Build Author

recoush

Views

9293

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

THE LINK

Views

5087

Build Author

THE LINK

Views

5087

2020 First build.

Probably cheapest DIY build youl see.