Build List

-

Active Filters:

x

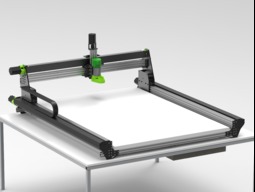

CNC Planning

Reusing parts to build a CNC - planning stage

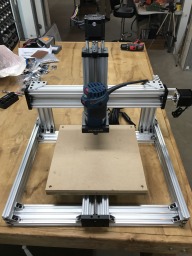

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Build Author

islahcnc

Views

4462

Build Author

islahcnc

Views

4462

islahcnc&design

I will post soon some more details.

Build Author

JerryD

Views

5347

Build Author

JerryD

Views

5347

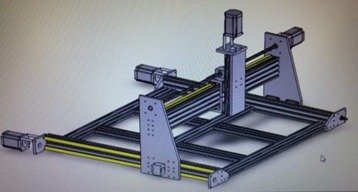

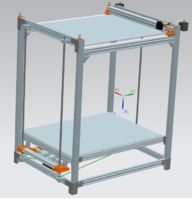

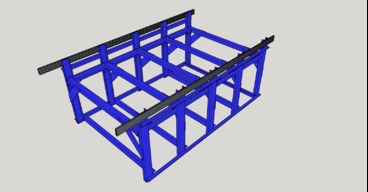

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

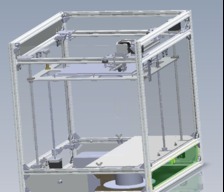

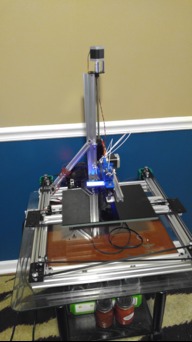

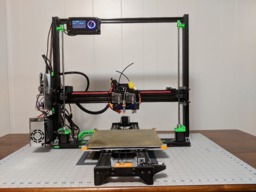

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Scotty Orr

Views

11670

Build Author

Scotty Orr

Views

11670

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

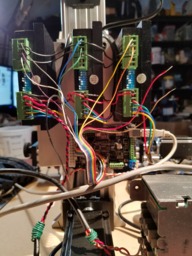

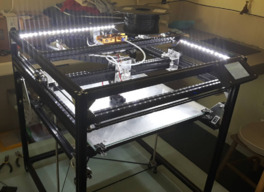

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

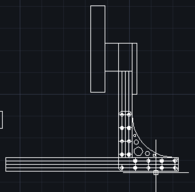

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4095

Build Author

Jason Harding

Views

4095

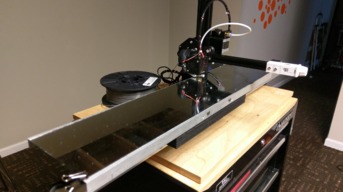

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

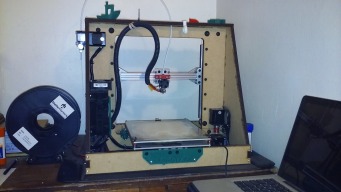

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

Tucstrlly

Views

9085

Build Author

Tucstrlly

Views

9085

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Build Author

TimVukman

Views

4315

Build Author

TimVukman

Views

4315

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Build Author

pedrofernandez

Views

12181

Build Author

pedrofernandez

Views

12181

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Terone Burgenheim

Views

6444

Build Author

Terone Burgenheim

Views

6444

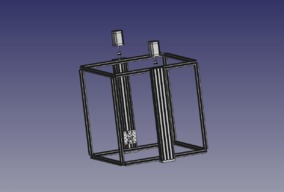

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

GDanger117

Views

12355

Build Author

GDanger117

Views

12355

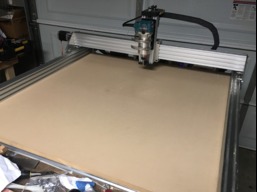

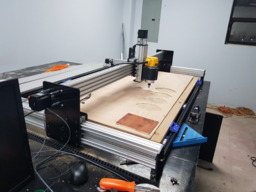

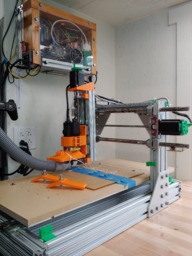

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

9009

Build Author

Lindsey Lewis

Views

9009

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5453

Build Author

Keith Davis

Views

5453

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

Camvec

Views

6276

Build Author

Camvec

Views

6276

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

Build Author

Nicademus

Views

9569

Build Author

Nicademus

Views

9569

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Rob Withoff

Views

5108

Build Author

Rob Withoff

Views

5108

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

TurfnSurf

Views

6218

Build Author

TurfnSurf

Views

6218

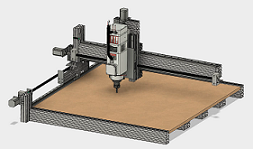

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

MattR

Views

20336

Build Author

MattR

Views

20336

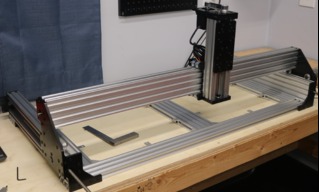

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Denis Lapratte

Views

4572

Build Author

Denis Lapratte

Views

4572

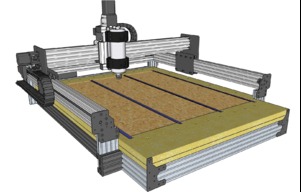

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

D-Bot Version B

D-Bot with a Replicate controller.

Build Author

bpatterson42

Views

3579

Build Author

bpatterson42

Views

3579

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

spark2

Views

5695

Build Author

spark2

Views

5695

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

Build Author

Sprags

Views

2742

Build Author

Sprags

Views

2742

C-Beam Kyo Sphinx 10060

More stuff here.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

Blyn3D

Views

6394

Build Author

Blyn3D

Views

6394

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

crnrstndes

Views

4239

Build Author

crnrstndes

Views

4239

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

BinaryConstruct

Views

10236

Build Author

BinaryConstruct

Views

10236

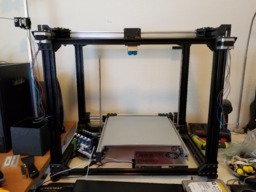

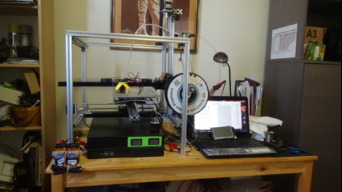

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Bucky Wootmaster

Views

3002

Build Author

Bucky Wootmaster

Views

3002

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Build Author

h3rb

Views

5732

Build Author

h3rb

Views

5732

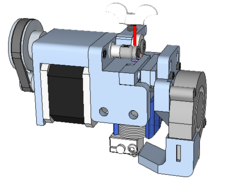

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

pedrofernandez

Views

7929

Build Author

pedrofernandez

Views

7929

ACRO 20x20

The Acro Laser Machine Build

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

Build Author

Axnfell

Views

3099

Build Author

Axnfell

Views

3099

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Build Author

Kevr102

Views

5841

Build Author

Kevr102

Views

5841

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Build Author

Hussein Dermay

Views

6514

Build Author

Hussein Dermay

Views

6514

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Big-X Minimill

Minimill bundle, but with an extended X Axis

DPR-v2 full metal

pictures and mony doku see later

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Build Author

ChrisViral

Views

7172

Build Author

ChrisViral

Views

7172

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

Mark Carew

Views

33847

Build Author

Mark Carew

Views

33847

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Todd Brous

Views

5672

Build Author

Todd Brous

Views

5672

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

Build Author

Rat Rig

Views

31616

Build Author

Rat Rig

Views

31616

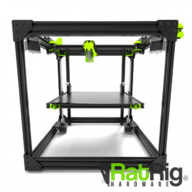

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

Build Author

Mark Carew

Views

17068

Build Author

Mark Carew

Views

17068

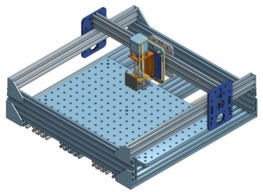

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Rehorst

Views

10184

Build Author

Mark Rehorst

Views

10184

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Mark Carew

Views

18380

Build Author

Mark Carew

Views

18380

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Andreas Bockert

Views

12008

Build Author

Andreas Bockert

Views

12008

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Butterfly 3DP V 1.0

tronxy x3 like

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Build Author

SCYBUCK

Views

5135

Build Author

SCYBUCK

Views

5135

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

Luke Cunningham

Views

5912

Build Author

Luke Cunningham

Views

5912

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Router for speargun hobby

First router build for speargun fabrication

Build Author

MrMojoRisin

Views

7597

Build Author

MrMojoRisin

Views

7597

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

CNC by MagicMarcus

CNC variation about Sphinx.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Build Author

Kyo

Views

45729

Build Author

Kyo

Views

45729

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Kraken Core-XY Printer

Core-XY build witha quad nozzle

Build Author

RobFromLDMS

Views

5259

Build Author

RobFromLDMS

Views

5259

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

James Evanko

Views

4850

Build Author

James Evanko

Views

4850

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

joetemus

Views

6843

Build Author

joetemus

Views

6843

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Build Author

Vin1027

Views

7345

Build Author

Vin1027

Views

7345

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Vegard Humlen

Views

5023

Build Author

Vegard Humlen

Views

5023

CNC Coating Machine

The purpose of this machine is to mix two parts of conformal coating with different viscosity in exactly 1:1 ratio and distribute the fluid on to PCB to seal and make it waterproof.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Build Author

Troy Proffitt

Views

29034

Build Author

Troy Proffitt

Views

29034

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Spark Concepts

Views

16690

Build Author

Spark Concepts

Views

16690

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Build Author

CoreCube3D

Views

22041

Build Author

CoreCube3D

Views

22041

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

Build Author

Christian James

Views

9989

Build Author

Christian James

Views

9989

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Big a** printer

In-progress 500x500x1800

Build Author

msdosfx

Views

6169

Build Author

msdosfx

Views

6169

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

Build Author

HuguesP

Views

7537

Build Author

HuguesP

Views

7537

Peristaltic pumps, Automatic Cocktail mixer

This is an automatic cocktail mixer made with 8 small peristaltic pumps. this is driven with the touch screen or over wifi. the controller used is a raspberry pi with a Apache webserver

Mushu - Large Scale CoreXY

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.

Build Author

RV6APilot

Views

4236

Build Author

RV6APilot

Views

4236

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.