Build List

-

Active Filters:

nt

Build Author

Christian James

Views

9916

Build Author

Christian James

Views

9916

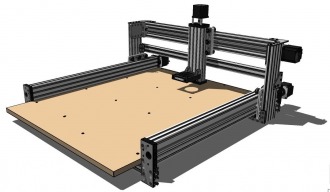

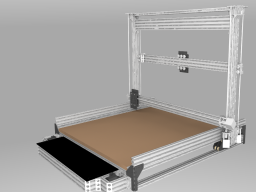

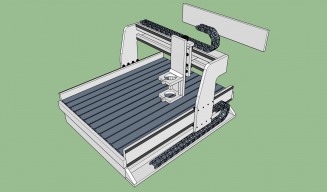

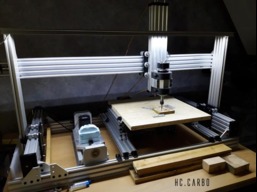

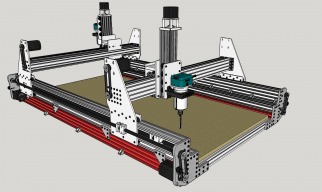

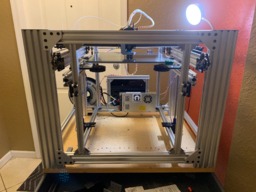

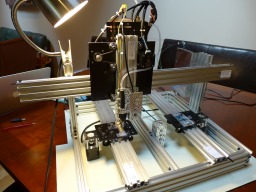

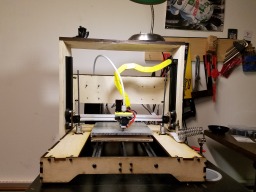

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

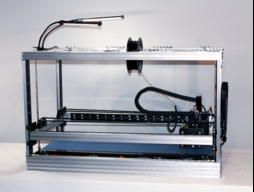

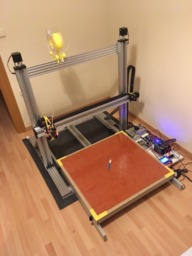

Horizontal Cantilever or Vertical Diode Laser Engraver

Light weight portable Laser Engraver (6.5lbs - 12lbs)

Build Author

deltajegga

Views

9879

Build Author

deltajegga

Views

9879

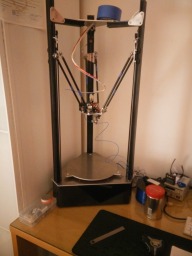

THE delta

probably as big as you'd want it...

Build Author

Ahmed Ibrahim

Views

9856

Build Author

Ahmed Ibrahim

Views

9856

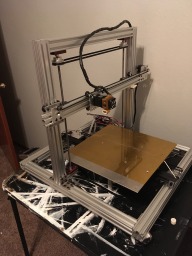

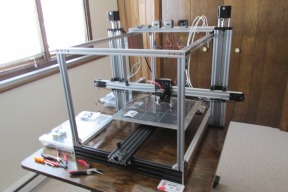

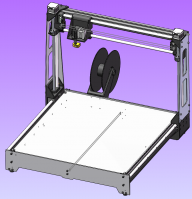

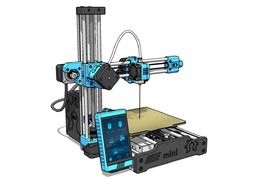

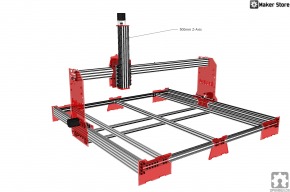

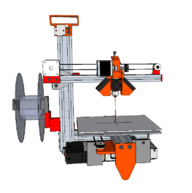

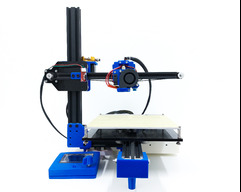

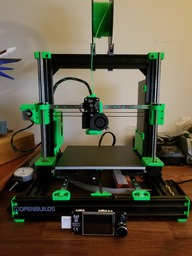

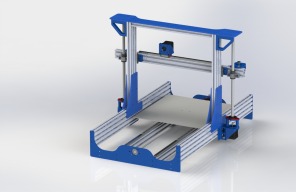

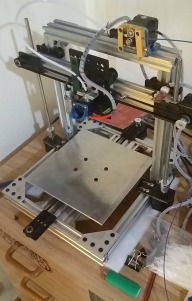

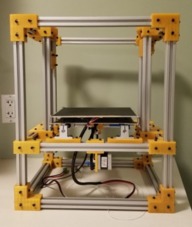

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

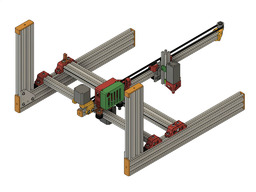

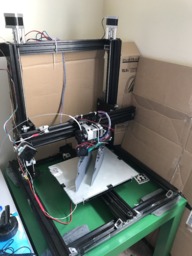

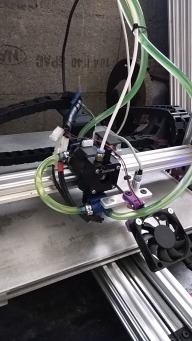

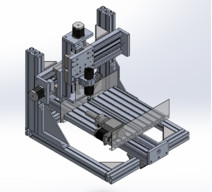

Voxel OX Based Build

Building upon the great work done by Marshall Peck and others. I have started a new build.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Build Author

Frank Del Favero

Views

9686

Build Author

Frank Del Favero

Views

9686

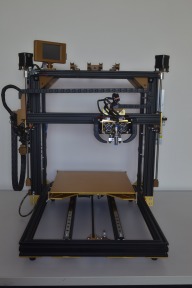

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Pelican Case 3D Printer

A portable 3D Printer that can flat pack into a hard carry case

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

Michael.M

Views

9647

Build Author

Michael.M

Views

9647

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

Build Author

Asaku

Views

9636

Build Author

Asaku

Views

9636

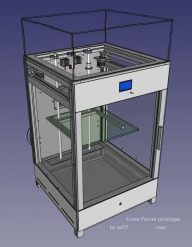

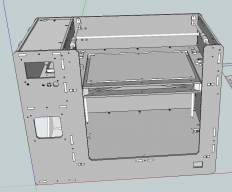

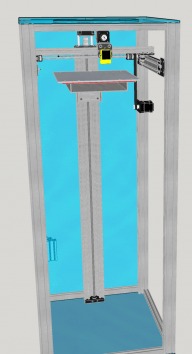

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

ACRO 150 X 150 CM

Openbuilds ACRO

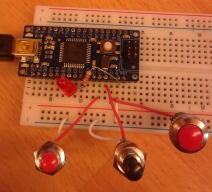

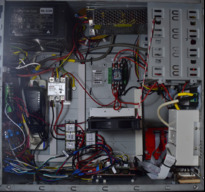

Controll Board for CNC Projects

The Echinus Team change the Firmware from "Teacup" to "Marlin". I use this board in my 3D Printer and it works very good! So I write a short report.

Build Author

Nicademus

Views

9539

Build Author

Nicademus

Views

9539

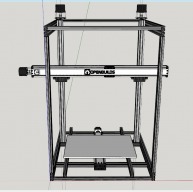

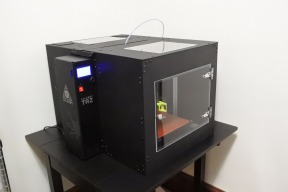

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

CreativeTools

Views

9459

Build Author

CreativeTools

Views

9459

Universal stand-alone filament spool holder (Fully 3D-printable)

A practical rotating and stand-alone spool holder which fits any filament extrusion 3D-printer. Several base files provided which make it fit different extruded aluminium profiles.

Build Author

Christer Langley

Views

9443

Build Author

Christer Langley

Views

9443

CNC-Solutions Build

My first Build with V-slot

Kool Bot

Mid range build.

Build Author

Jesse Jenkins

Views

9403

Build Author

Jesse Jenkins

Views

9403

Hedron's build with Ooznest kit and Xylotex motors

A 3-axis flying gantry (4'x4') mechanical kit is assembled. A 3D printer is used to make cable chain for tidy and cheap wire management. A BeagleBone Black development platform with Machinekit software (LinuxCNC) is configured to control a Xylotex motor driver box connected to an Openbuilds Ox direct-drive pulley and belt motion system. A vacuum dust-collection system is designed, CNC-routed and installed. A steel table is made to mount the table onto.

Build Author

Rwetzler

Views

9350

Build Author

Rwetzler

Views

9350

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

Gooshpoo

Views

9301

Build Author

Gooshpoo

Views

9301

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Build Author

Sergio Di Ventura

Views

9292

Build Author

Sergio Di Ventura

Views

9292

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

openhardwarecoza

Views

9281

Build Author

openhardwarecoza

Views

9281

3D Printer 320x220x200

Someone donated a E3D Volcano to me (http://e3d-online.com/Volcano/V6-VOLCANO-POWER-PACK-175-UNIVERSAL-24V) and with a super hotend like that, it feels like a waste to stick it into a small 3D printer. So I decided I want a 320x220mm (XY) machine, 200mm Z is plenty for me

Build Author

Mike Andrews

Views

9262

Build Author

Mike Andrews

Views

9262

Monster - a multiple material 3D printer with 20"(X) X 14"(Y) X ~20"(Z)

A Laut3k derivative that goes for volume and large number of print materials at the same time. Using OpenBuild linear motion systems to get away from belt drives.

Build Author

griso

Views

9250

Build Author

griso

Views

9250

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

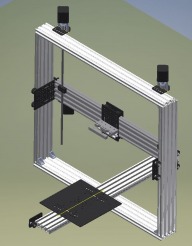

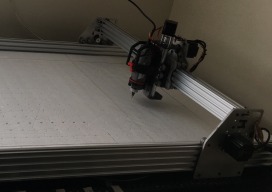

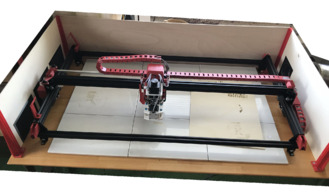

Laser cutter project by students

This build is made by students from Fontys Hogescholen Eindhoven, department Engineering. Every quarter a new group continues the work of the previous group. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser.

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

J-Wahl Dezign

Views

9132

Build Author

J-Wahl Dezign

Views

9132

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

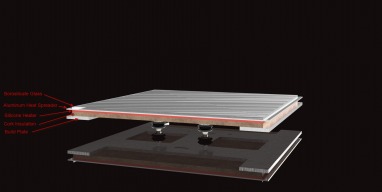

12.5" x 12" Assembled Heated Build Plate

Custom build plate for 300mm x 300mm (12"x12"). The hole pattern is for the 20x60 V Slot

Build Author

Lindsey Lewis

Views

8983

Build Author

Lindsey Lewis

Views

8983

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Tinker

Views

8948

Build Author

Tinker

Views

8948

Kitchen Space Saver

The frame is made from all open builds parts, add the rubber feet and pads for the glass. The glass is clear 12" x 16" x 1/4" with a polished edge. A light basket slides on the countertop.

Build Author

Mohsen Abbasi

Views

8944

Build Author

Mohsen Abbasi

Views

8944

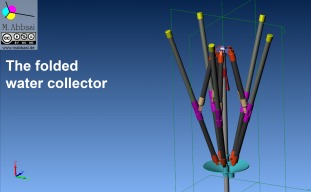

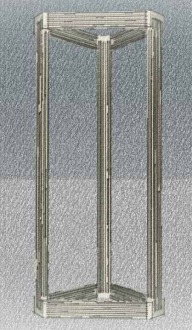

Foldable Rainwater Collector

Realisation of my idea about a foldable collector for rainwater, which is light and easy to make. People around the world need water and can collect rain water with this collector. I made it for syria and all too.

Build Author

sgspenceley

Views

8941

Build Author

sgspenceley

Views

8941

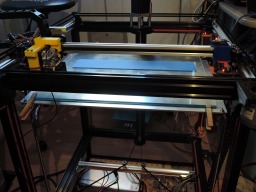

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Metalguru's C-Beam 750

This is a C-Beam build, fairly heavy duty, and 750mm x 750mm. Should be a good, sturdy machine that's relatively easy to assemble.

Build Author

Krishnakumar

Views

8709

Build Author

Krishnakumar

Views

8709

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

taratata2016

Views

8569

Build Author

taratata2016

Views

8569

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

mikev

Views

8568

Build Author

mikev

Views

8568

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Limine3D

Views

8549

Build Author

Limine3D

Views

8549

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

HAPP Printer

This 3D Printer is made to provide the most accurate results with the least amount of investment. This Printer is being designed to allow the common user to own a very accurate piece of machinery.

Build Author

rcKeith

Views

8547

Build Author

rcKeith

Views

8547

USB Hot Wire CNC Foam Cutter

Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics.

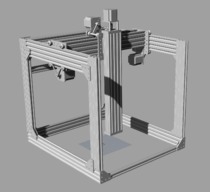

Tower Printer

Tower Printer H-Belt type printer Prototype

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

Build Author

Joe F

Views

8463

Build Author

Joe F

Views

8463

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Build Author

Carl van Heezik

Views

8395

Build Author

Carl van Heezik

Views

8395

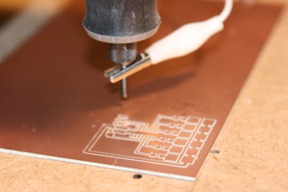

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

MikieLikesIt

Views

8242

Build Author

MikieLikesIt

Views

8242

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

DoubleX

This is a Dual X-axis platform.

cera.tops Clay 3d Printer

This 3d printer framework was designed for use with the ceraStruder clay 3D printing extruder. More info coming soon.

Build Author

Lindsey Lewis

Views

8144

Build Author

Lindsey Lewis

Views

8144

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Sketchup Design of a PVC CNC I Intend to build.

Build Start to begin Feb 1st.

ME-Mini 3D Printer

Prusa mini inspired 3d printer

First Ever Build

This is my first attempt at building my own 3d printer.

Build Author

Jay Almers

Views

8001

Build Author

Jay Almers

Views

8001

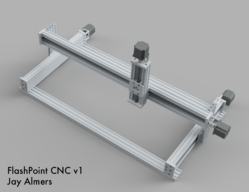

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Build Author

Hilleke

Views

7838

Build Author

Hilleke

Views

7838

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Build Author

Sam Dobbie

Views

7789

Build Author

Sam Dobbie

Views

7789

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

3D Printer DELTA

Delta printer, Bed size 280 cm dimeter Print Height 300 cm not tested yet the speed

Build Author

OffAxis

Views

7709

Build Author

OffAxis

Views

7709

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

JoeH

Views

7647

Build Author

JoeH

Views

7647

COTSPnP

The COTSPnP pick-and-place machine (PnP) is used to place surface-mount devices (SMDs) onto a printed circuit board and was designed and built exclusively from off-the-shelf (COTS) components, predominantly sourced from OpenBuilds and Actobotics. Its intended use is prototyping and not high rate, high volume production and is capable of precisely placing parts as small as 0402 capacitors and resistors but more importantly, can precisely place components with lead spacing as small a 0.4mm.

Build Author

Carl Siren

Views

7636

Build Author

Carl Siren

Views

7636

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Mini Additive Manufacturing Printer by Chris Scholl

Mini Additive Manufacturing Printer by Chris Scholl

Build Author

MrMojoRisin

Views

7558

Build Author

MrMojoRisin

Views

7558

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.

Panther Printer - Lautr3k

My version of the popular Lautr3k 3D printer. UNI Panther colors of Purple and Yellow on black V-slot rails. 300x300 bed.

18x36x16 Inch 3D Printer - Work in progress

Tough 3D Printer using OpenBuilds Parts!

XDrive 3d Printer

XDrive 3d printer, high quality large build volume.

Watercooled 3D printer : Maximus Evo Rev 2

Watercooled 3D printer

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Build Author

Josh Mascote

Views

7393

Build Author

Josh Mascote

Views

7393

Z3D Delta Printer

Berrybot inspired delta 3d printer with a few other tweaks and modifications.

Build Author

evgeny156

Views

7319

Build Author

evgeny156

Views

7319

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

James Evanko

Views

7258

Build Author

James Evanko

Views

7258

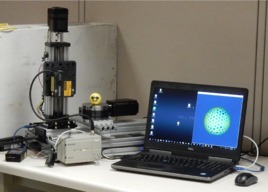

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Build Author

Jacob Christiansen

Views

7241

Build Author

Jacob Christiansen

Views

7241

ACRO 1010 with custom Z axis

This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting.

Build Author

Jonathon Duerig

Views

7190

Build Author

Jonathon Duerig

Views

7190

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

francesco pollina

Views

7117

Build Author

francesco pollina

Views

7117

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.

Build Author

TurfnSurf

Views

7114

Build Author

TurfnSurf

Views

7114

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Easy to build and robust 3D printer framework

Lord willing I will be showing you how build a robust and easy to build 3D printer framework using V-Slot rails and rollers. It's a little bulky, but it has all spring tensioned rollers on all axes, and can be built entirely without custom machining on any parts. You will need digital calipers, a drill press, a carbide toothed miter saw for cutting aluminum extrusions, and lots of little screws!

Build Author

Jose A. Molina

Views

6990

Build Author

Jose A. Molina

Views

6990

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

andrizzle

Views

6983

Build Author

andrizzle

Views

6983

Printer1

Open source 3D printer with very powerful heated bed and light weight x axis design. Full source repository can be found here: https://github.com/a-drizzle/Printer1

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Build Author

Tommy Williamson

Views

6949

Build Author

Tommy Williamson

Views

6949

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Jose A. Molina

Views

6933

Build Author

Jose A. Molina

Views

6933

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

Build Author

Bruno Rivard

Views

6903

Build Author

Bruno Rivard

Views

6903

OB Heavy duty Prusa i3 "Lunar Injection"

Hell Yeah

Build Author

rkugler

Views

6820

Build Author

rkugler

Views

6820

Miter Saw Stop Block

Just starting a miter saw stop system. Any suggestions appreciated.

Simpl3rBot

A framing design for cantilever style printers

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

Build Author

Vunnie

Views

6790

Build Author

Vunnie

Views

6790

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

OpenBuilds

Views

6706

Build Author

OpenBuilds

Views

6706

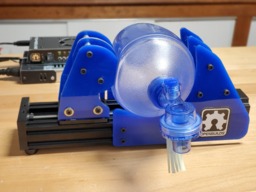

V-Slot Ventilator

The idea is to make a simple effective ventilator, studying the concept of using a simple push process with and actuator.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Openbuilds CubeBot 3D Printer

Cartesian type 3d printer build

Build Author

dodgenet

Views

6584

Build Author

dodgenet

Views

6584

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

USB Pendant

An USB Pendant for LinuxCNC / Mach3

Build Author

Kyo

Views

6513

Build Author

Kyo

Views

6513

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

Liam Dahler

Views

6506

Build Author

Liam Dahler

Views

6506

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.