Build List

Build Author

signzonepr

Views

12967

Build Author

signzonepr

Views

12967

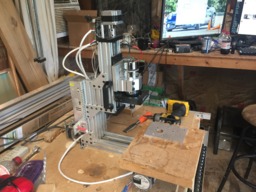

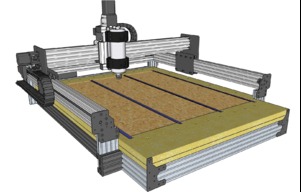

HD c Beam CNC Router

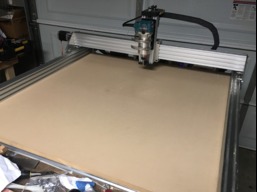

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Savvas

Views

14337

Build Author

Savvas

Views

14337

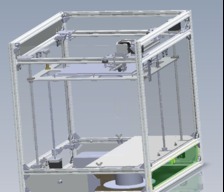

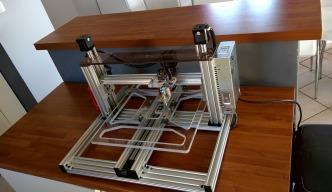

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Jones

Views

3900

Build Author

Jones

Views

3900

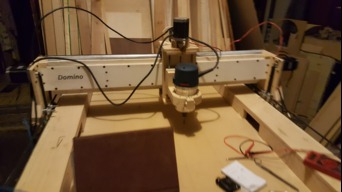

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

My Little Mashup

A mixed drive, PI Controlled machine

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

eTrueUp Glide

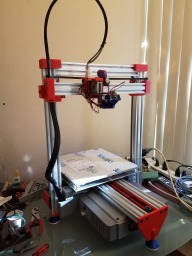

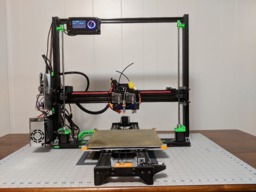

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

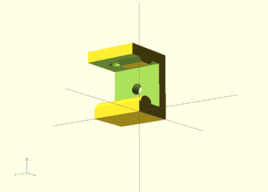

DIN 35mm -like quick clip for 20mm extrusion

A half baked idea for mounting electrics and electronics using a 35mm-DIN-rail-like mounting.

My is just the biggest printer. with a printable area - 1760 x 1146 x 1318h

I myself invented this concept printer form

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Build Author

Kyo

Views

6463

Build Author

Kyo

Views

6463

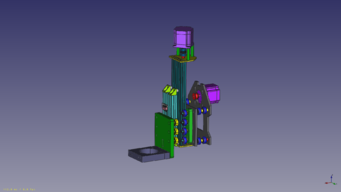

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

mytechno3d

Views

28367

Build Author

mytechno3d

Views

28367

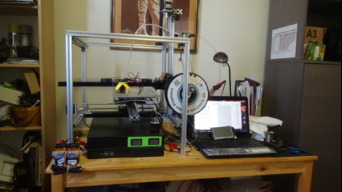

Maximus Evolution (Still another XL 3D Printer )

Maximus Evolution : 380mm x 400mm XL 3D Printer

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Build Author

Hilleke

Views

7716

Build Author

Hilleke

Views

7716

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Galvos

3d printable galvos

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Nicademus

Views

9439

Build Author

Nicademus

Views

9439

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

stepper

Views

4475

Build Author

stepper

Views

4475

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

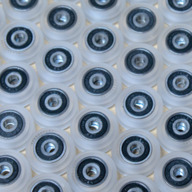

Textile machine bearing structures CNC engraving machine

With the textile machine bearing feel better strength, better durability 用纺织机轴承感觉强度要好一些,耐用性更好

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

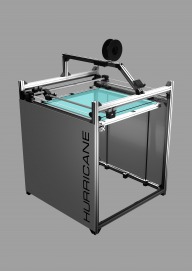

Hurricane - Large 80cm x 80cm x 80cm cm build space project

Huge - Fast - Affordable

Build Author

Carl Siren

Views

7557

Build Author

Carl Siren

Views

7557

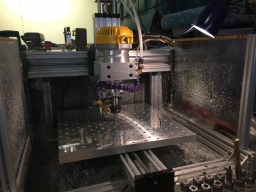

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

thehans

Views

6590

Build Author

thehans

Views

6590

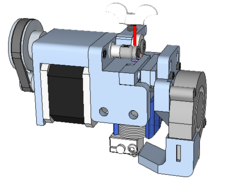

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

pedrofernandez

Views

12107

Build Author

pedrofernandez

Views

12107

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Mark Rehorst

Views

10091

Build Author

Mark Rehorst

Views

10091

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Glenn Weston

Views

18127

Build Author

Glenn Weston

Views

18127

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

Colin Russon

Views

9317

Build Author

Colin Russon

Views

9317

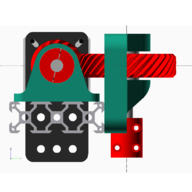

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

BinaryConstruct

Views

10125

Build Author

BinaryConstruct

Views

10125

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Gary Caruso

Views

24710

Build Author

Gary Caruso

Views

24710

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Sword66

Views

13845

Build Author

Sword66

Views

13845

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Julius

Views

25313

Build Author

Julius

Views

25313

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

2671

Build Author

Sprags

Views

2671

C-Beam Kyo Sphinx 10060

More stuff here.

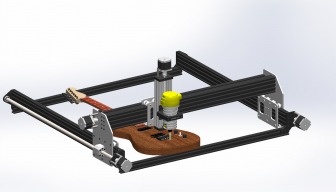

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

Mark Carew

Views

87770

Build Author

Mark Carew

Views

87770

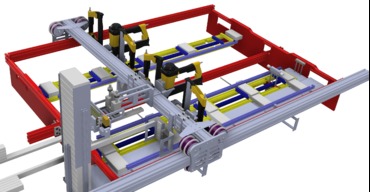

V-Slot™ Belt & Pinion Example Build

The OpenBuilds team has redefined the belt and pinion concept. By using standard OpenBuild components were able to improve on this system in ways that will save on cost and enhance its engineering capabilities.

Build Author

Beam

Views

11413

Build Author

Beam

Views

11413

DIY Flywheel Camera Slider

My take on a non affordable slider.

Build Author

jpjoshua

Views

13046

Build Author

jpjoshua

Views

13046

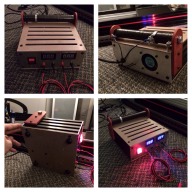

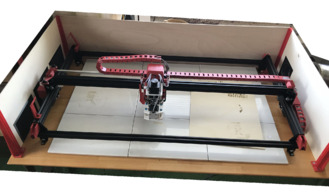

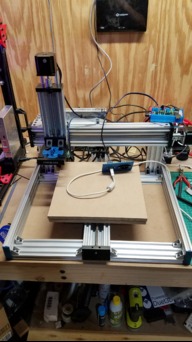

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

DPR-v2 full metal

pictures and mony doku see later

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Laser engraver

Just a little light duty laser engraver.

Big-X Minimill

Minimill bundle, but with an extended X Axis

V-Slot MAME cabinet

A minimalist MAME "cabinet" made from extrusion.

Build Author

TurfnSurf

Views

6154

Build Author

TurfnSurf

Views

6154

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

DIY anodizing power supply

How to make your own anodizing power supply on a budget

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Keith Davis

Views

5365

Build Author

Keith Davis

Views

5365

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Build Author

Brandon Satterfield

Views

7618

Build Author

Brandon Satterfield

Views

7618

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Build Author

Hussein Dermay

Views

6398

Build Author

Hussein Dermay

Views

6398

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

C_Beam Hammerhead 5x

setup for learning 5x

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Axnfell

Views

3008

Build Author

Axnfell

Views

3008

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Janis93

Views

15420

Build Author

Janis93

Views

15420

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Build Author

pedrofernandez

Views

7839

Build Author

pedrofernandez

Views

7839

ACRO 20x20

The Acro Laser Machine Build

Build Author

Tommy Williamson

Views

6780

Build Author

Tommy Williamson

Views

6780

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

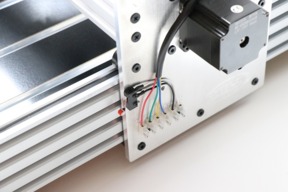

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

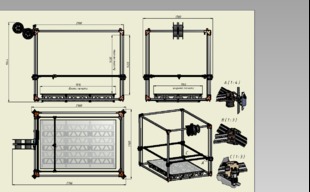

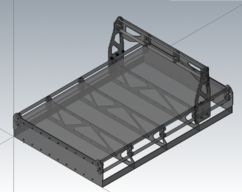

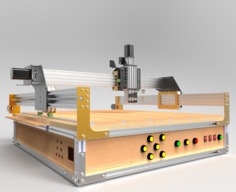

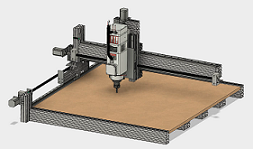

Something a Tad different

Future CNC router kit design

Build Author

Limine3D

Views

4437

Build Author

Limine3D

Views

4437

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

Calotype

Views

3529

Build Author

Calotype

Views

3529

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

obmilllivebuild

Views

5562

Build Author

obmilllivebuild

Views

5562

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

Andre Cooke

Views

17415

Build Author

Andre Cooke

Views

17415

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Gooshpoo

Views

9215

Build Author

Gooshpoo

Views

9215

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

h3rb

Views

5598

Build Author

h3rb

Views

5598

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Naomi Wu

Views

10653

Build Author

Naomi Wu

Views

10653

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

uGen

Views

18493

Build Author

uGen

Views

18493

Lab Power Supply + Soldering Station

A small 32 V, 96 W lab power supply with voltage/current/power limit, program memory and an outlet to power the popular TS-100 soldering iron

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Weldsmith

Views

7638

Build Author

Weldsmith

Views

7638

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Build Author

TimVukman

Views

4250

Build Author

TimVukman

Views

4250

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

h3rb

Views

3679

Build Author

h3rb

Views

3679

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

Jose A. Molina

Views

6858

Build Author

Jose A. Molina

Views

6858

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Big CNC plasma cutter

more later

Build Author

Blyn3D

Views

6293

Build Author

Blyn3D

Views

6293

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

ymilord

Views

22215

Build Author

ymilord

Views

22215

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

hbtousa

Views

3194

Build Author

hbtousa

Views

3194

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

Bucky Wootmaster

Views

2932

Build Author

Bucky Wootmaster

Views

2932

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

OffAxis

Views

7620

Build Author

OffAxis

Views

7620

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

crnrstndes

Views

4105

Build Author

crnrstndes

Views

4105

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

JAC_101

Views

5970

Build Author

JAC_101

Views

5970

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

jz321

Views

4468

Build Author

jz321

Views

4468

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.