Build List

-

Active Filters:

c

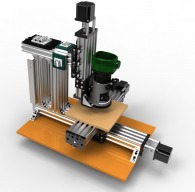

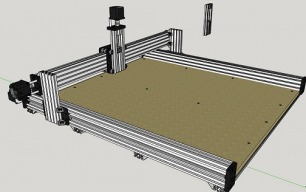

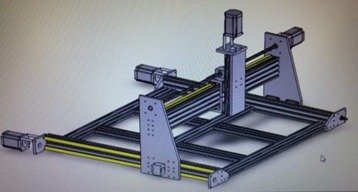

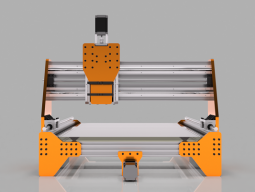

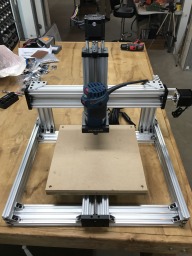

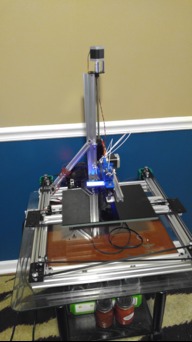

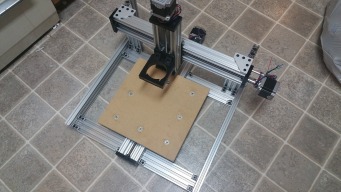

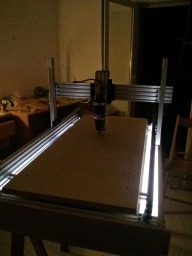

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

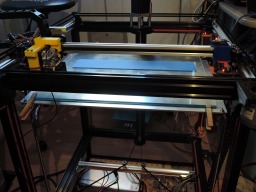

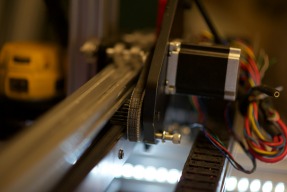

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Build Author

Tucstrlly

Views

9189

Build Author

Tucstrlly

Views

9189

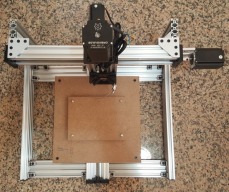

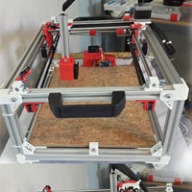

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

Terone Burgenheim

Views

6578

Build Author

Terone Burgenheim

Views

6578

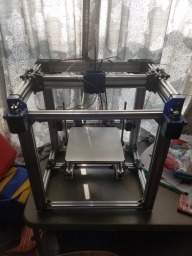

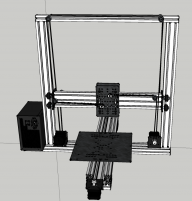

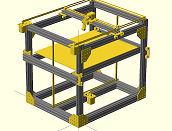

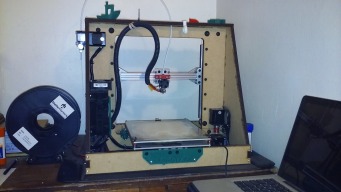

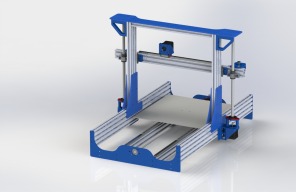

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Terone Burgenheim

Views

2876

Build Author

Terone Burgenheim

Views

2876

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

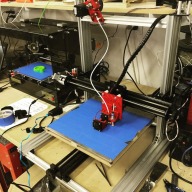

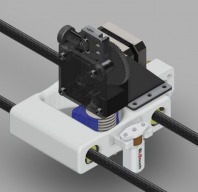

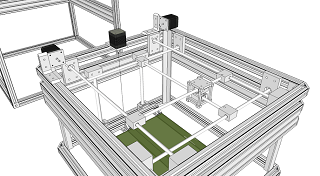

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

ZacharyB

Views

5867

Build Author

ZacharyB

Views

5867

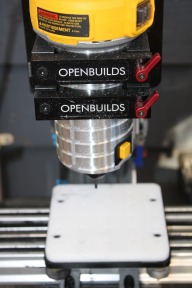

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

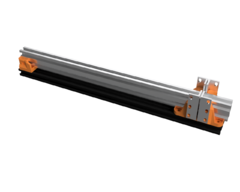

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

patdee

Views

5236

Build Author

patdee

Views

5236

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

William Niedermeyer

Views

19843

Build Author

William Niedermeyer

Views

19843

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Build Author

jamesdjadams

Views

12350

Build Author

jamesdjadams

Views

12350

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

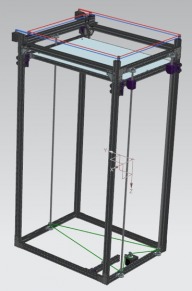

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Laser Mount

This is a mount I wanted to build for a laser project using OpenBuilds part router mount.

Ancient Roland Table top Mill

The parts are now very reasonable.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

Joerharris

Views

6638

Build Author

Joerharris

Views

6638

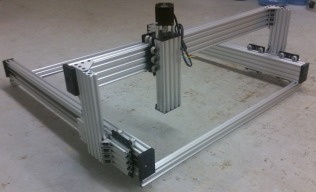

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

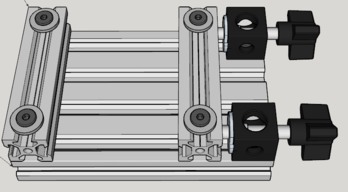

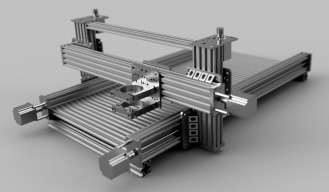

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

Build Author

ymilord

Views

19635

Build Author

ymilord

Views

19635

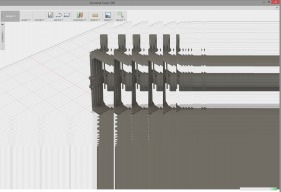

Small Portable PCB CNC Machine (CoreXY)

This is a small CNC mill/router specifically for manufacture PCBs. This is based on the corexy gantry setup. The plan is to have a small, light self-contained machine that can be used and easily but away when it's job is done.

Build Author

DaveStewart

Views

6255

Build Author

DaveStewart

Views

6255

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Build Author

Kyo

Views

10308

Build Author

Kyo

Views

10308

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

MakerSL style vice - using just off-the-shelf-parts (NB UNTESTED WIP)

An attempt at copying the https://openbuilds.com/builds/makersl-msl-8-ob-vise.4084/ using just off-the-shelf OpenBuilds Parts - no machining

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

Build Author

CubeSpawn

Views

19899

Build Author

CubeSpawn

Views

19899

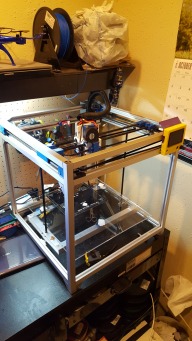

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

Build Author

zelos

Views

19439

Build Author

zelos

Views

19439

ZelosLaser Engraver/Cutter 2.0 : Sturdy & Versatile

Zelos Laser Cutter Version 2.0 GRBL Shield with Nema 17 motors. 2 Watt laser for cutting and fine grayscale pictures built very sturdy and modular

Build Author

ymilord

Views

12817

Build Author

ymilord

Views

12817

Kyoujin Mk1 (C-Beam /w Rack & Pinion)

C-Beam based CNC with Rack & Pinion (for the X Axis) and lead screws (for the Y Axis)

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

Karan Singh Sisodia

Views

8999

Build Author

Karan Singh Sisodia

Views

8999

CNC Laser

CoreXY based CNC Laser machine.

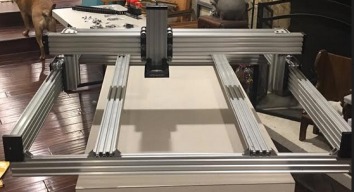

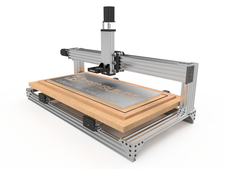

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

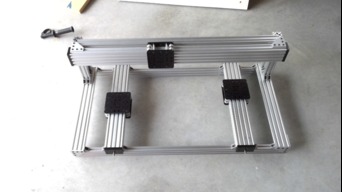

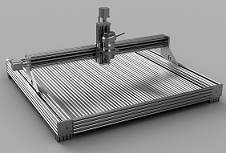

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Mini D-Bot

A smaller version of a standard D-bot. Smaller to fit better in my workable area and to fit my vision for the printer.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

pek

Views

6675

Build Author

pek

Views

6675

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

OX CNC Router

Ca fait 2 ans que je rêve d'une Fraiseuse CNC. Ni trop grande ni trop petite, sans avoir le budget pour en acheter une toute faite. Je suis artisan menuisier ébéniste et j'ai finalement décidé de la construire. Le projet OX m'a séduit, alors je me lance.

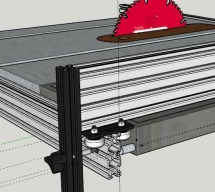

Table Saw Fence

Trying to build a low cost table saw fence using v-wheels

The Almost Perfect 3 Way Mitre (with MakerLinks)

A quick and easy way to make a 3-way mitered corner using MakerLinks

Build Author

Anthony Castelluci

Views

3290

Build Author

Anthony Castelluci

Views

3290

Simple Camera Lofted Camera Slider

Build a manual camera slider.

OXilla - a 3ft x 3ft CNC Router/Mill - Goals are strength, power and speed

This will be an ongoing log as I build this machine. Name change by popular demand - at least a couple of us. :)

The Frog: CNC Router

Frog CNC Router. Inspired by OX and "Routy". 24"x36" active working area, approx. 3" usable Z motion.

C-Beam XXLarge "Laser "Tank""

A re-imagining of Dollarz81's XXL Tank in Laser form

Table saw fence and guide

The idea was to build a proof of concept table saw fence similar to a thru-rip or accusquare fences which retail for 400$, with the added option to motorize the positioning.

Build Author

PaulS

Views

20732

Build Author

PaulS

Views

20732

UltiFaker 2 Go

This is a breakdown of how I designed the UltiFaker 2 Go as well as how I machined and assembled it. I'll include a complete BOM and all of the drawings and prices.

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Lead screw printer

High quality e3d parts with a minimalist design

Heavy duty C Beam

a 1000mm x 1500mm CBeam build with hgr20 hiwin rails 600w er16 spindle

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4172

Build Author

Jason Harding

Views

4172

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Build Author

francesco pollina

Views

7260

Build Author

francesco pollina

Views

7260

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.

Build Author

JP Warnke

Views

12938

Build Author

JP Warnke

Views

12938

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Build Author

Scotty Orr

Views

11932

Build Author

Scotty Orr

Views

11932

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

Build Author

Hisha

Views

8936

Build Author

Hisha

Views

8936

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

Greg Lampman

Views

9332

Build Author

Greg Lampman

Views

9332

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

C beam xl

I would recommend this challenge to any woodworker looking for something new.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

MY NEW CNC

This build is not based on the ox, but got my ideas and inspiration from my first build,

Build Author

Pol Feliu

Views

9330

Build Author

Pol Feliu

Views

9330

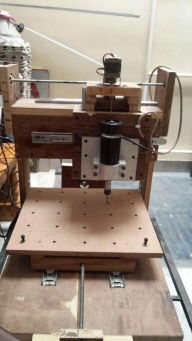

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

Build Author

islahcnc

Views

4517

Build Author

islahcnc

Views

4517

islahcnc&design

I will post soon some more details.

Build Author

JerryD

Views

5411

Build Author

JerryD

Views

5411

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

M^3

Views

22220

Build Author

M^3

Views

22220

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Justin Butler

Views

9515

Build Author

Justin Butler

Views

9515

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Build Author

Robert Bailey

Views

29537

Build Author

Robert Bailey

Views

29537

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

Karan Singh Sisodia

Views

6431

Build Author

Karan Singh Sisodia

Views

6431

My Home made CNC

Home Made CNC Router from Scrape

Build Author

Sonny Lowe

Views

7086

Build Author

Sonny Lowe

Views

7086

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Build Author

sgspenceley

Views

9214

Build Author

sgspenceley

Views

9214

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Venturebit

Views

14047

Build Author

Venturebit

Views

14047

SHRED-Buddy3D UPcycler - Open Source Multi Material Cutter&Pelletizer

The whole system is powered by 12V / DC power. Process it into Pellets or Granules to use it with your 3D Printer or Filament Extruder. Our self-developed steppermotor Controls allows you to optimally adjust Feedrate for your Situation. Forward, Backward and Stop is integrated for easy operation. The Speed can be continuously regulated via rotary switch.

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

1x1m Ooznest Ox

Building my first router and I choose the ooznest Ox since it looks to be the latest and greatest among routers.

Dixie C-Beam XL

Build log of the Dixie C-Beam XL CNC Router.

Build Author

Fabio Orsi

Views

7025

Build Author

Fabio Orsi

Views

7025

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)