CNC ROUTER BUILDS

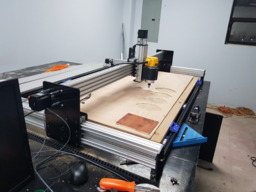

Workbee 1010

Hey all looking forward to sharing this build, I’ve learned a lot reviewing many of these great builds.

Build Author

DaleShaw

Views

4477

Build Author

DaleShaw

Views

4477

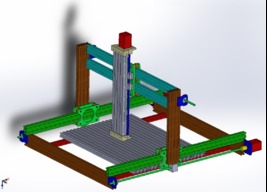

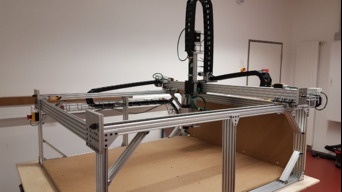

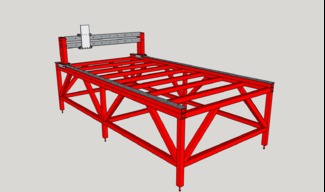

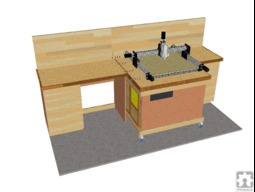

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

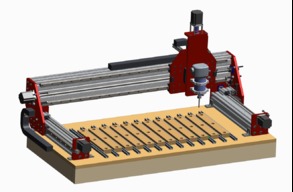

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

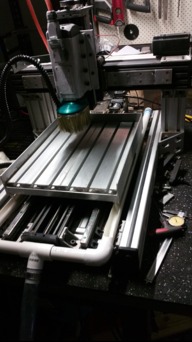

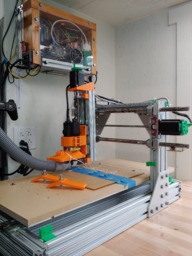

A More Rigid C-Beam

I added the steel to create a less flexible milling surface to make heavier cuts in aluminum. I can also do light steel cutting now as well. I wish OpenBuilds made a steel and rail version of these kits.

Build Author

Andrew Helsel

Views

12177

Build Author

Andrew Helsel

Views

12177

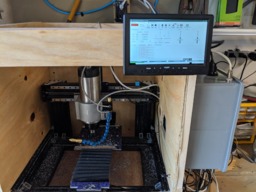

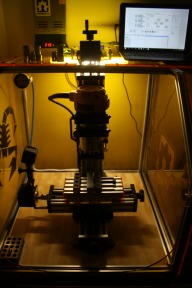

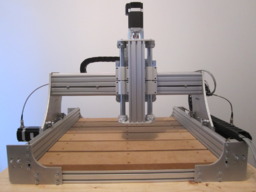

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

Neil Scott

Views

3261

Build Author

Neil Scott

Views

3261

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Build Author

SecretSpy711

Views

22589

Build Author

SecretSpy711

Views

22589

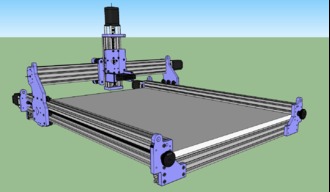

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

My Workbee build

Workbee, 1000mmX750mm , from China

Build Author

Vunnie

Views

6807

Build Author

Vunnie

Views

6807

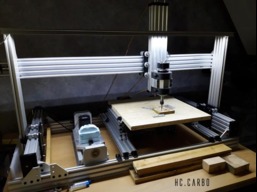

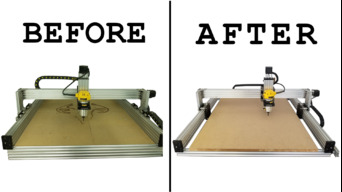

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

Fábio Pires

Views

7055

Build Author

Fábio Pires

Views

7055

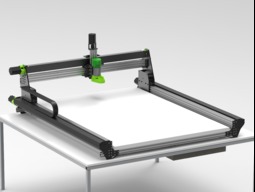

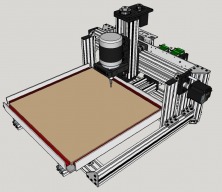

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Rise of the Sphoenix

I am building a Sphinx 55 from the bones of my old C-Beam machine. Rising from the ashes so to speak.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

tmadrms

Views

7727

Build Author

tmadrms

Views

7727

C-Beam Mods

C-beam machine mods.

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Build Author

MattR

Views

20336

Build Author

MattR

Views

20336

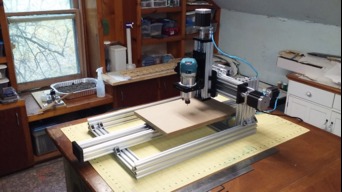

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Craig Hollabaugh

Views

4897

Build Author

Craig Hollabaugh

Views

4897

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

"Stung by the Bee" OB Workbee 1010 Build

This will be a build Log for my Open Builds Workbee 1010 Build. I will keep a full descriptive log of the build and make any notes in the hope that it will help other builders that decide they would like to build this machine.

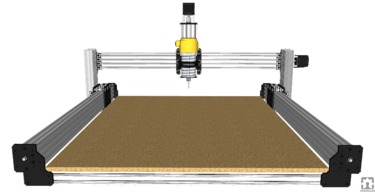

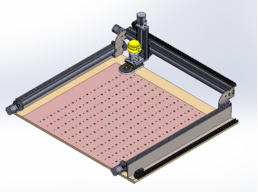

BKE Lead 1010 - First CNC Router

LEAD CNC

Build Author

reef

Views

12005

Build Author

reef

Views

12005

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

Build Author

Lasersc

Views

10468

Build Author

Lasersc

Views

10468

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

Build Author

viktop

Views

18577

Build Author

viktop

Views

18577

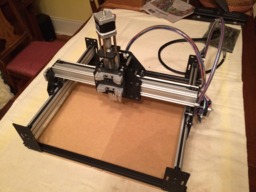

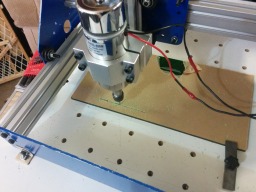

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

CNC Router Machine

CNC Router with working area 550*550*200

Openbuilds C-beam

This is a build supported by Ooznest by a team of girls in Year 8 (12/13 years old) to machine model F1 cars for the F1 in Schools competition.

C_Beam X5L Hybrid_Tank

classic router with a ab table

Build Author

roadss

Views

26022

Build Author

roadss

Views

26022

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

75x75

Simple cnc with 5mm steel plates.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

Workbee 1015 (50" wide by 30")

A Workbee able to cut 48"x24" material, built to continuously feed material so one can cut full sheets of ply.

Build Author

msdosfx

Views

6169

Build Author

msdosfx

Views

6169

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

CBeam Sphinx Upgrade

Simple upgrade of the Y axis on a Cbeam sphinx from 500mm to 1000mm.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

KronBjorn

Views

4478

Build Author

KronBjorn

Views

4478

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

RobFromLDMS

Views

5260

Build Author

RobFromLDMS

Views

5260

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

RV6APilot

Views

4236

Build Author

RV6APilot

Views

4236

South Carolina Workbee 1000X1000

This is about my build of a Workbee 1000X1000 being built here in Trenton, SC. My goal is to use it to help cut the new panel for my RV6A airplane.

Build Author

Stan Howe

Views

3351

Build Author

Stan Howe

Views

3351

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

John J Talavera

Views

18706

Build Author

John J Talavera

Views

18706

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

Mark Carew

Views

36613

Build Author

Mark Carew

Views

36613

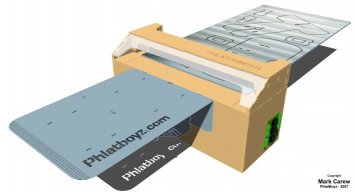

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

Build Author

Mark Carew

Views

75529

Build Author

Mark Carew

Views

75529

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Build Author

MarkM_NJ

Views

20003

Build Author

MarkM_NJ

Views

20003

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

DTG OX

From where Mark left off from the Ox build I am going to film the whole process of customizing the Ox.

Build Author

Cortellini

Views

5599

Build Author

Cortellini

Views

5599

the Feedback Fractal project

The Story of the Scecina Memorial High School 1510 BUILD will unfold through a series of 10 minute Episodes. Each episode will consist of video showing how to assemble some aspect of the 1510 overlaid with a discussion about Technology, Art, Philosophy... and Life the Universe and Everything. Episode two is soon to follow. If sufficient interest ensues, the episodes may continue beyond the building of the 1510 to relate its use in the making of the Art.

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Shapeoko 2 - my first CNC

This was my first foray into CNC. I chose to go with a reliable kit build since my knowledge of GCode, controllers, and steppers was pretty rudimentary.

Build Author

Bikes and Beer

Views

4869

Build Author

Bikes and Beer

Views

4869

The Forever Project

Workbee 1010 Lead Screw with water cooled spindle and enclosure

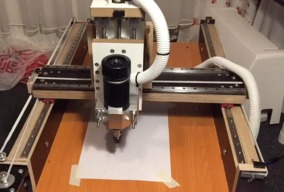

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

CharlieShimota

Views

16233

Build Author

CharlieShimota

Views

16233

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

C-Beam Machine Build

This is my first CNC router build. I want to gain basic CNC building experience so I can go on to build other items such as a frosting or pancake printer.

Build Author

Metalguru

Views

14687

Build Author

Metalguru

Views

14687

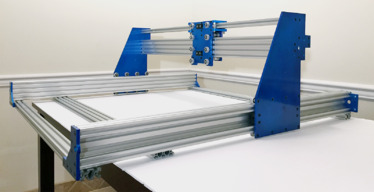

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

OpenBuilds LEAD Machine 1010 40" x 40"

Openbuilds LEAD machine 1010 build

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

OoozNest WorkBee

A Journey on the WorkBee Build...

WorkLead, no wait, LeadBee, naw... WoodWorker

Improvements on the Lead machine using some Workbee parts

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

Build Author

Christian James

Views

9990

Build Author

Christian James

Views

9990

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Build Author

TurfnSurf

Views

7149

Build Author

TurfnSurf

Views

7149

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Doug Rowley

Views

4348

Build Author

Doug Rowley

Views

4348

My Workbee 1010

This is a workbee 1010 build using the mechanical parts from Open Builds. The electrical and electronic parts were from a prior build of a Root 3 CNC by Sailor Pete.

Build Author

joetemus

Views

6843

Build Author

joetemus

Views

6843

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

Router for speargun hobby

First router build for speargun fabrication

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

Rob Mahan

Views

13769

Build Author

Rob Mahan

Views

13769

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

CNC by MagicMarcus

CNC variation about Sphinx.

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

My Shapeoko Router build

I built this as it is a small portable design.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

Lindsey Lewis

Views

8188

Build Author

Lindsey Lewis

Views

8188

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

ChrisViral

Views

7172

Build Author

ChrisViral

Views

7172

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

James Evanko

Views

4097

Build Author

James Evanko

Views

4097

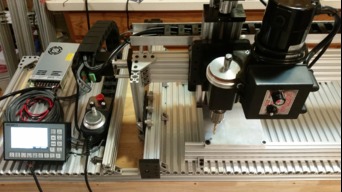

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

rob4cnc

Views

4030

Build Author

rob4cnc

Views

4030

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

Rick Holder

Views

15437

Build Author

Rick Holder

Views

15437

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

1075 Sphinx

My first attempt at building a CNC. I chose the Sphinx due to ease of build and extensive documentation provided by Kyo.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Build Author

SCYBUCK

Views

5135

Build Author

SCYBUCK

Views

5135

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Michael.M

Views

9682

Build Author

Michael.M

Views

9682

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.