Build List

Build Author

David Hartkop

Views

3092

Build Author

David Hartkop

Views

3092

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

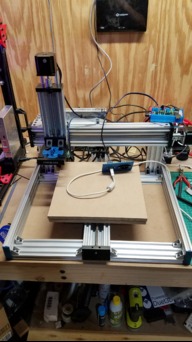

Sphinx 7575

Sphinx CNC modified to 750mm x 750mm c-beams. Parts not readily available in South Africa, so i have to make some modifications...

Build Author

Eric Jacobsson

Views

15572

Build Author

Eric Jacobsson

Views

15572

The Floating Dust Shoe

I wanted a dust shoe that have a easy access to tool change and something that kind of float on the surface. And I have seen shoes with long brush that sucked in by the vacuum. I think I have the solution too all that here.

Build Author

Rob Mahan

Views

14001

Build Author

Rob Mahan

Views

14001

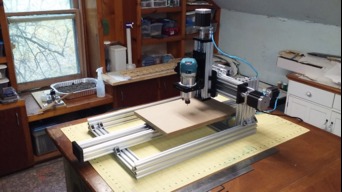

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

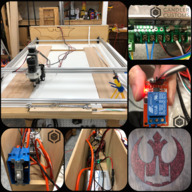

CNC by MagicMarcus

CNC variation about Sphinx.

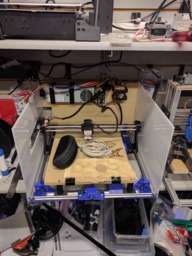

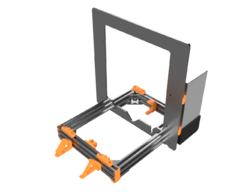

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

My Shapeoko Router build

I built this as it is a small portable design.

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Delta without vertices

As this is a build in progress, I will update it as I progress.

Build Author

Lindsey Lewis

Views

8340

Build Author

Lindsey Lewis

Views

8340

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

ChrisViral

Views

7250

Build Author

ChrisViral

Views

7250

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

James Evanko

Views

4171

Build Author

James Evanko

Views

4171

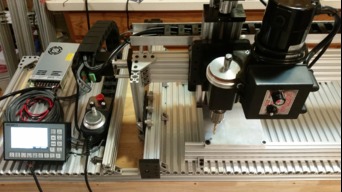

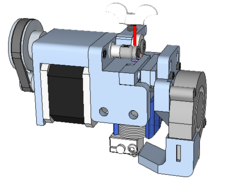

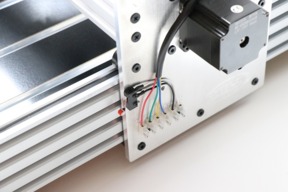

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

Another OX CNC Router

An OX CNC router using Blue OX Solutions gantry plates, a Bosch Colt router, and most of the remaining parts coming from Openbuilds parts store. Table has about 22"x55" cutting capacity and I am planning on a combination T-Slot and vacuum hold down system.

Build Author

James Evanko

Views

4933

Build Author

James Evanko

Views

4933

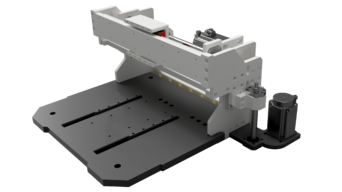

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

MMXL - A MiniMill Conversion

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

Build Author

Rick Holder

Views

15500

Build Author

Rick Holder

Views

15500

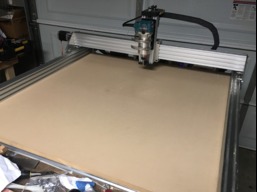

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

Luke Cunningham

Views

5951

Build Author

Luke Cunningham

Views

5951

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Phil's MiniMill

A quick little mini mill build

Build Author

Kevr102

Views

5922

Build Author

Kevr102

Views

5922

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Build Author

signzonepr

Views

13112

Build Author

signzonepr

Views

13112

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Savvas

Views

14487

Build Author

Savvas

Views

14487

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

Jones

Views

4060

Build Author

Jones

Views

4060

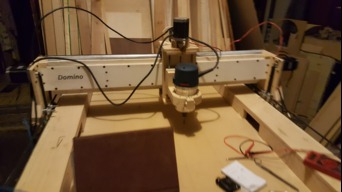

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

Yet another 1x1 Sphinx

Build a 1x1 Sphinx/Sphinx XL style CNC.

Build Author

Hilleke

Views

7931

Build Author

Hilleke

Views

7931

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Build Author

stepper

Views

4607

Build Author

stepper

Views

4607

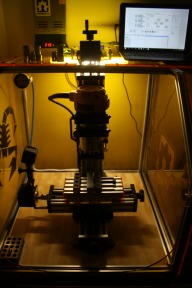

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

Textile machine bearing structures CNC engraving machine

With the textile machine bearing feel better strength, better durability 用纺织机轴承感觉强度要好一些,耐用性更好

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

thehans

Views

6750

Build Author

thehans

Views

6750

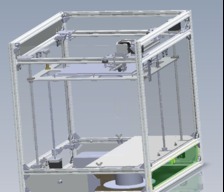

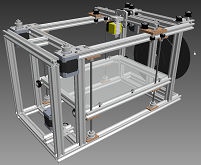

Voxel OX with Helix Gear Z Transmission (single z motor)

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

Build Author

pedrofernandez

Views

12259

Build Author

pedrofernandez

Views

12259

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

Mark Rehorst

Views

10268

Build Author

Mark Rehorst

Views

10268

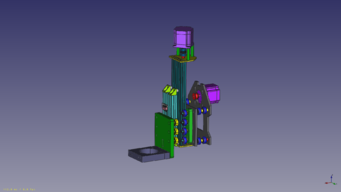

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Glenn Weston

Views

18420

Build Author

Glenn Weston

Views

18420

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

BinaryConstruct

Views

10298

Build Author

BinaryConstruct

Views

10298

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Gary Caruso

Views

25031

Build Author

Gary Caruso

Views

25031

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Julius

Views

25584

Build Author

Julius

Views

25584

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

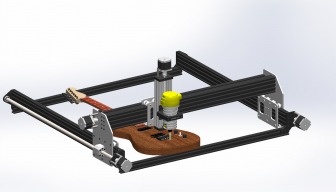

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

Beam

Views

11750

Build Author

Beam

Views

11750

DIY Flywheel Camera Slider

My take on a non affordable slider.

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

DPR-v2 full metal

pictures and mony doku see later

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

Keith Davis

Views

5513

Build Author

Keith Davis

Views

5513

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

Brandon Satterfield

Views

7783

Build Author

Brandon Satterfield

Views

7783

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

20x24 inch Fixed Gantry Mill

I have shared many pictures of this project it is now complete I have had my first cuts on this machine and it is solid , still learning the new motion Controller. The Acorn is more like you would find on a commercial built CNC or CNC Lathe.But it does have all of the functionally one needs

C_Beam Hammerhead 5x

setup for learning 5x

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

pedrofernandez

Views

8005

Build Author

pedrofernandez

Views

8005

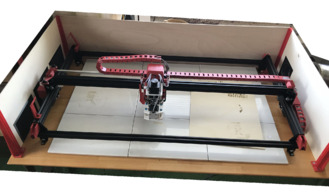

ACRO 20x20

The Acro Laser Machine Build

Build Author

Tommy Williamson

Views

7175

Build Author

Tommy Williamson

Views

7175

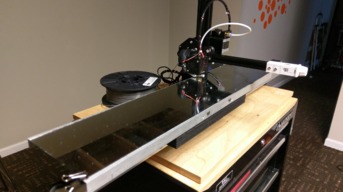

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Build Author

Limine3D

Views

4680

Build Author

Limine3D

Views

4680

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

Calotype

Views

3644

Build Author

Calotype

Views

3644

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

obmilllivebuild

Views

5698

Build Author

obmilllivebuild

Views

5698

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

Andre Cooke

Views

17741

Build Author

Andre Cooke

Views

17741

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

Naomi Wu

Views

10934

Build Author

Naomi Wu

Views

10934

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

uGen

Views

18679

Build Author

uGen

Views

18679

Lab Power Supply + Soldering Station

A small 32 V, 96 W lab power supply with voltage/current/power limit, program memory and an outlet to power the popular TS-100 soldering iron

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

h3rb

Views

3820

Build Author

h3rb

Views

3820

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Hybrid shapeoko Xcarve cnc router

My scratch build using shapeoko, xcarve, and custom parts.

Build Author

hbtousa

Views

3353

Build Author

hbtousa

Views

3353

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

crnrstndes

Views

4299

Build Author

crnrstndes

Views

4299

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

JAC_101

Views

6157

Build Author

JAC_101

Views

6157

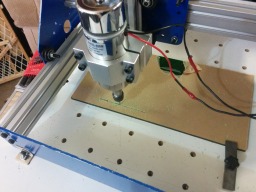

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Build Author

jz321

Views

4632

Build Author

jz321

Views

4632

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Build Author

north90

Views

15309

Build Author

north90

Views

15309

OpenSampler: OpenSource autosampler for use in laboratory

An open source autosampler to be used in laboratories for the automated analysis of gas or liquid samples.

OKMI 3d Printer

OKMI 3d Printer based on CoreXY

Another Kyo inspired Sphinx

A 1000mm x 1000mm copy of Kyo's Sphinx

VoS

3D Printer based upon 3d printed parts and open builds componets

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Huub65

Views

9436

Build Author

Huub65

Views

9436

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

pek

Views

27193

Build Author

pek

Views

27193

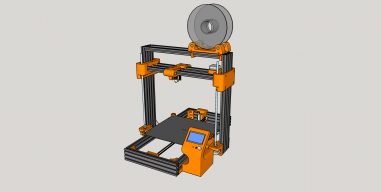

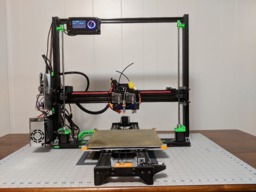

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

Rakmup

Views

41522

Build Author

Rakmup

Views

41522

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

C-Beam 1M

Basing this build on the C-Beam machine XL on the parts store, but added a few things to make it more like the C-Beam XXLarge "Tank" by Dollarz81. Going with the Dewalt 611 instead of a water cooled spindle at first. May change down the road. Using a Panucat Gradus M1 controller with BigFoot drivers.

Build Author

dmasters

Views

8298

Build Author

dmasters

Views

8298

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

Build Author

GDanger117

Views

12489

Build Author

GDanger117

Views

12489

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Chetan PM

Views

3883

Build Author

Chetan PM

Views

3883

Composer

Gantry style rigid build

Build Author

ShockingTops

Views

4552

Build Author

ShockingTops

Views

4552

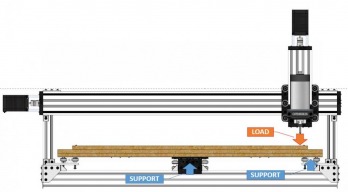

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Miter Saw Station

A Miter Saw station built using a Dewalt Miter Saw Stand and V-Slot extrusions.

New 2 watt laser platform

Acro based 2 watt laser platform

Build Author

jtaggard

Views

37579

Build Author

jtaggard

Views

37579

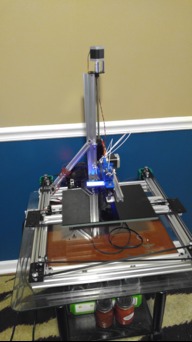

Modular DIY CNC Machine

This modular CNC machine is based on the OpenBuilds ACRO System, however I wanted something that did more than just laser engrave. So I designed my machine using the same style as the ACRO but with some upgrades such as an actual Z-axis and the ability for multiple tool attachments.

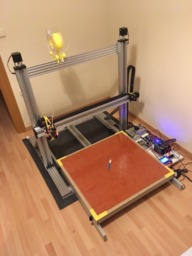

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Build Author

George Motichka

Views

3823

Build Author

George Motichka

Views

3823

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

CandlerCustoms

Views

5642

Build Author

CandlerCustoms

Views

5642

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Build Author

RJ_Make

Views

6197

Build Author

RJ_Make

Views

6197

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Router Box

This box is made from tough aluminum with plastic boards, helps hold WiFi Routers, Modems, or/ Ethernet Switches! The aluminum can resist the heat produced by these electronics, and the weight of the electronics, also being light itself. This box is the thing you need to hold your electronic devices!

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Build Author

Terone Burgenheim

Views

6541

Build Author

Terone Burgenheim

Views

6541

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.