Build List

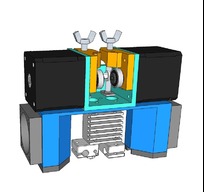

GIGAWATT 2.1 LASER CUTTER

Progetto di un laser CO2 da 50w Autocostruito, con scheda di controllo MKS Sbase v.1.3 Firmware Smoothieware versione CNC Struttura realizzata con profili T-slot 20x20 e 20x40

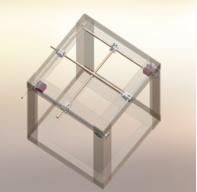

Atlas Delta Bot

The idea here is to build a nice large delta bot from the parts ground on the one builds part store. Other parts that are sources out side of this will be detailed. I have a simple BOM I started that I will upload later.

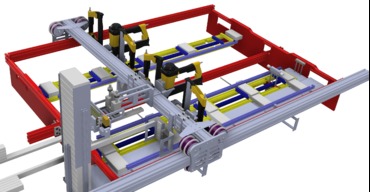

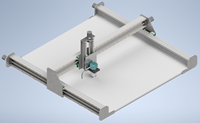

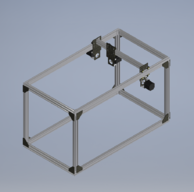

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

Build Author

Srđan Marković

Views

4039

Build Author

Srđan Marković

Views

4039

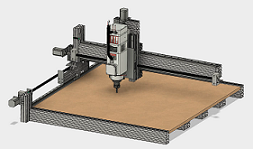

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

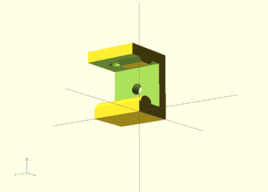

DIN 35mm -like quick clip for 20mm extrusion

A half baked idea for mounting electrics and electronics using a 35mm-DIN-rail-like mounting.

Build Author

rob4cnc

Views

4036

Build Author

rob4cnc

Views

4036

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

theracermark

Views

4034

Build Author

theracermark

Views

4034

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

Build Author

Robert Huxford

Views

4005

Build Author

Robert Huxford

Views

4005

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

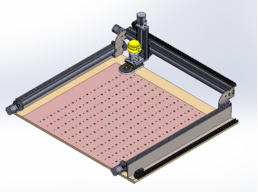

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Build Author

Colin Russon

Views

3942

Build Author

Colin Russon

Views

3942

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

MidnightQuads

Views

3912

Build Author

MidnightQuads

Views

3912

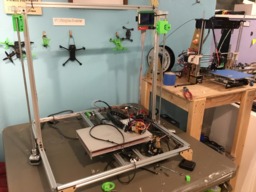

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Ancient Roland Table top Mill

The parts are now very reasonable.

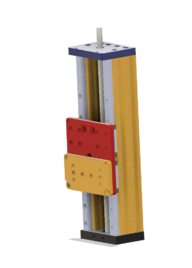

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

Build Author

Rich Bowen

Views

3853

Build Author

Rich Bowen

Views

3853

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

Build Author

Thair.nl

Views

3822

Build Author

Thair.nl

Views

3822

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

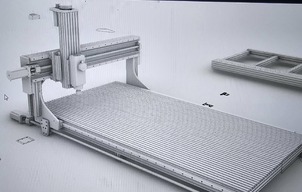

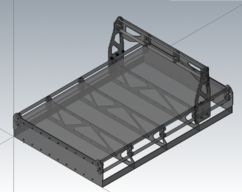

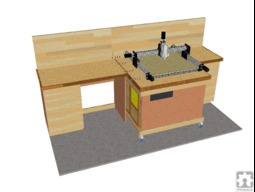

Custom Ski and Snowboard CNC for a High School Woodwhop

A Custom size CNC to make custom skis and snowboards

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

Build Author

Ken376

Views

3762

Build Author

Ken376

Views

3762

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

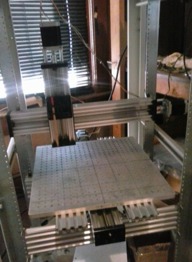

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

McAdam

Views

3752

Build Author

McAdam

Views

3752

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Denford CNC Resurrection

Denford CNC Mill Update

3D Printer 051

Functional real-world 3D printer build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK 25mm linear rails/trucks.

Pen Plotter

All metal A3 CoreXY pen plotter

Build Author

Rodrigo Gonzalez

Views

3661

Build Author

Rodrigo Gonzalez

Views

3661

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Clock repair stand

Open source clock movement stand

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

A work in progress

One of my first projects might be cutting proper plates.

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

My 5' by 5'

I have constructed frame out of 1 1/2" square tubing. Have my Y aces mounted. and awaiting parts.

Build Author

bpatterson42

Views

3584

Build Author

bpatterson42

Views

3584

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Router for speargun hobby

First router build for speargun fabrication

My Workbee build

Workbee, 1000mmX750mm , from China

Build Author

Daniel.korneliussen

Views

3530

Build Author

Daniel.korneliussen

Views

3530

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

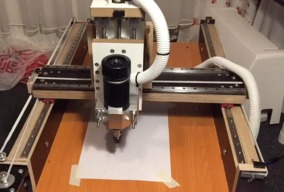

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

Phlat Printer 3 meets Open Builds

I will go over the attachments for the PP3 Z axis. soon. Before any thing else .You need to know the first PP3 ,used SKP 7 and Mach 3. Later on they used CNC USB.

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

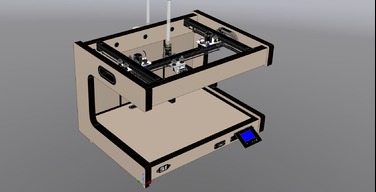

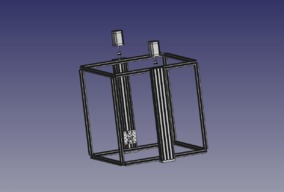

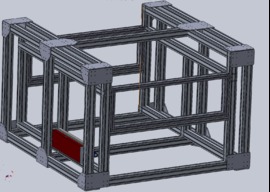

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

David E. Flores E.

Views

3398

Build Author

David E. Flores E.

Views

3398

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Build Author

Stan Howe

Views

3359

Build Author

Stan Howe

Views

3359

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Genetoys

Views

3347

Build Author

Genetoys

Views

3347

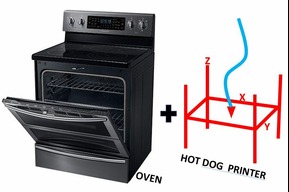

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

Dual Direct Drive Extruder

a dual extruder build using direct drive for flexible filaments

Just Starting

My attempt at planning out my own CNC router

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Build Author

Neil Scott

Views

3282

Build Author

Neil Scott

Views

3282

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

K-Cup Sealer

This is a K-Cup sealer i constructed does a fine job

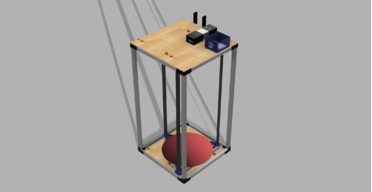

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

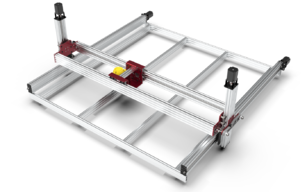

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Build Author

Linkreincarnate

Views

3152

Build Author

Linkreincarnate

Views

3152

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Build Author

Sir Bagels

Views

3129

Build Author

Sir Bagels

Views

3129

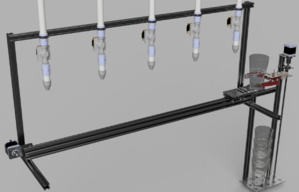

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

Axnfell

Views

3113

Build Author

Axnfell

Views

3113

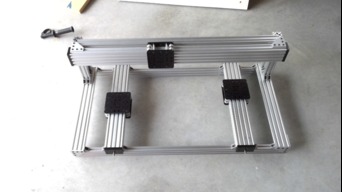

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Gary Caruso

Views

3093

Build Author

Gary Caruso

Views

3093

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

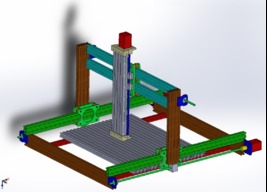

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

TFE2 CNC Build

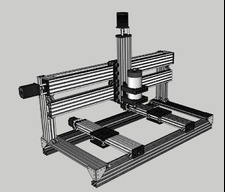

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

Workbee with less irritations

My workbee build with some add ons

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Bucky Wootmaster

Views

3007

Build Author

Bucky Wootmaster

Views

3007

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

Build Author

mjenkins5720

Views

2958

Build Author

mjenkins5720

Views

2958

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Something a Tad different

Future CNC router kit design

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Starting the next Laser build, Plan to complete within 60 days.

Black Box/ Power supply brackets

This items are so cool that they need to be together, so I decided to create brackets that connect both pieces together

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Large format laser

Large format laser build for Student use at my school as well as some personal use.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

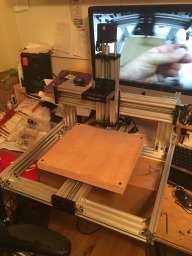

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

Sprags

Views

2752

Build Author

Sprags

Views

2752

C-Beam Kyo Sphinx 10060

More stuff here.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

CNC Router Machine

CNC Router with working area 550*550*200

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.