Build List

-

Active Filters:

x

Build Author

Paul Amelang

Views

5704

Build Author

Paul Amelang

Views

5704

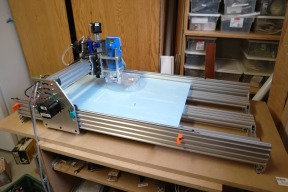

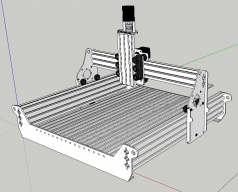

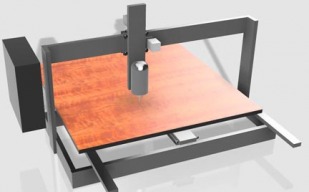

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Build Author

Gary Caruso

Views

3084

Build Author

Gary Caruso

Views

3084

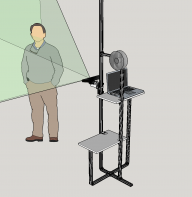

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Build Author

OpenBuilds

Views

31963

Build Author

OpenBuilds

Views

31963

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

Build Author

BCulbertson

Views

5102

Build Author

BCulbertson

Views

5102

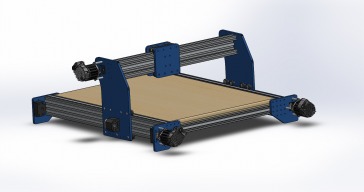

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Build Author

Bear

Views

11060

Build Author

Bear

Views

11060

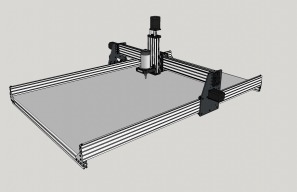

OXBear

ANOTHER OX!~ Huge Thanks to Marc Carew and Open Builds. The primary reason I am building this CNC mill is to aid in my homemade snowboard creation. I am going to try and document as much of everything as I can and post it here to help others going a similar route. I know from past projects that taking the time to document each step can be tedious when you want to charge ahead but I will try! I hoping to get feedback on my design choices and set up as I am a complete newbie to CNC.

Yet Another Ox Build

This build log will chronicle the construction of my oversize (1000mm X 1500mm) OX router.

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

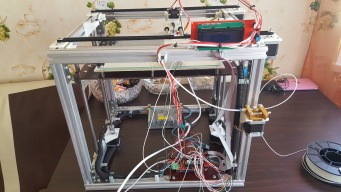

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

Build Author

openhardwarecoza

Views

7138

Build Author

openhardwarecoza

Views

7138

Pocket Ox (Sheetmetal)

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot

Vic Aussie Ox

Dove in and ordered the kit from Makerstore in Melbourne. While awaiting for the order watched videos and sourced steppers and controllers from China. Had some fun with the 4 axis TB6600 controller board. Ran into a few problems with the build, but after stripping and restarting looks like I am on track.

Build Author

Skoobs

Views

4955

Build Author

Skoobs

Views

4955

Pretty Standard + Slave X Axis

Planning my build, just looking for design input at the moment. I definitely want a slave X axis. I am potentially going to go with one of the 1500W Chinese water cooled spindles.

Zebu ( OX clone with Brasil materials)

An OX clone with alternative parts.

Square OX

Square shaped OX for doing general purpose engraving and cutting into wood, acrylic, and aluminum.

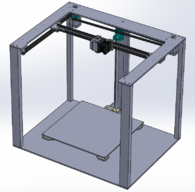

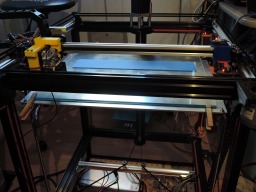

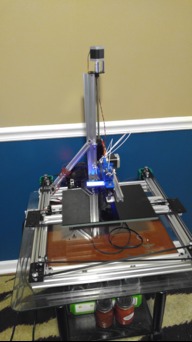

XYZ Factory Bot

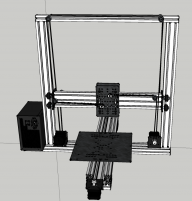

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

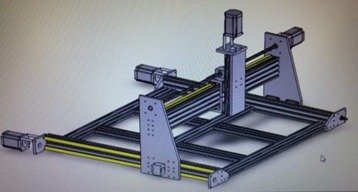

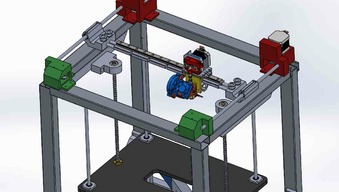

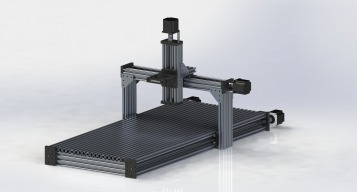

The MULE (an OX inspired 3-axis CNC)

The Mule is a 3-axis CNC inspired by the OX CNC by Mark Carew. This machine borrows the OX's sturdy frame and upgrades the X and Y linear actuators through the use of three 500mm lead screws (as opposed to the belt system of the OX). The result is an inexpensive, sturdy, and powerful design built for cutting tough materials such as aluminum.

Ooznest OX CNC Build

Ooznest OX CNC build

Build Author

Nwrgordon

Views

15907

Build Author

Nwrgordon

Views

15907

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Arctic Ox CNC Router

This is a cartesian CNC Router build that is based off the OX CNC build by Mark Carew. I am using Spark Concepts CNC xPro controller board and their 400w spindle kit.

Build Author

evil2002usna

Views

11573

Build Author

evil2002usna

Views

11573

Evil Ox

Cheap Ballscrew Ox CNC Router.

Build Author

Paruk

Views

23161

Build Author

Paruk

Views

23161

Buffal-O-Tron

A 3D Scanning Station

Build Author

Dave420

Views

6160

Build Author

Dave420

Views

6160

Dave's Z axis and powder coated.

I just did my first Powder coat paint job on a Z Axis with 9inchs of travel for the DIY CNC Plasma Cutter, Mill Head, Router, Engraver, Laser Head, Water Jet Cutter Machine. 2 different Z Axis ride plates and a 80mm Router/Mill Head/Spindle clamp. Baked on finish in a old oven i had.

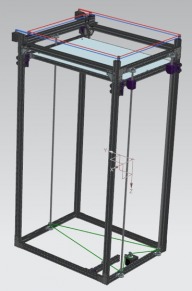

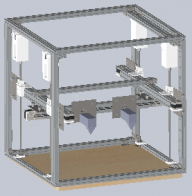

Core XY My-BOT 500 x 500 x 1000

My first construction after many years buys ready devices.

Build Author

eddyg

Views

5002

Build Author

eddyg

Views

5002

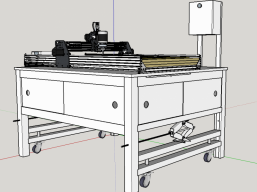

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Zen3D Atlantis 3D printer, H-Bot mechanics

H-Bot mechanics 3D printer. Build volume - 300x300x300mm dimensions: 560x500x500mm

Build Author

Dave420

Views

14526

Build Author

Dave420

Views

14526

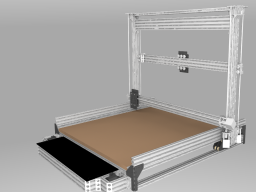

10 x 5 ft plazma table build

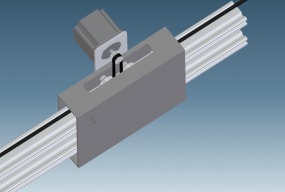

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

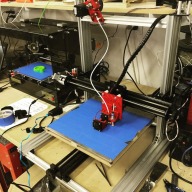

Openbuilds D-Bot

A humble first time attempt at building a 3d printer from scratch

Build Author

dodgenet

Views

6607

Build Author

dodgenet

Views

6607

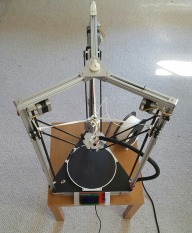

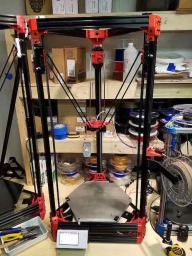

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Dmknerr

Views

5228

Build Author

Dmknerr

Views

5228

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

3D Meister

Views

5532

Build Author

3D Meister

Views

5532

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

recoush

Views

9296

Build Author

recoush

Views

9296

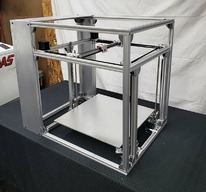

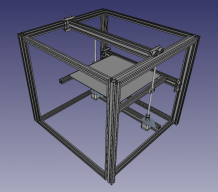

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

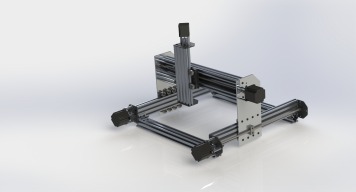

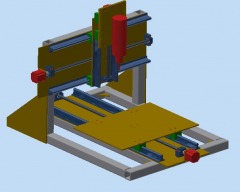

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4096

Build Author

Jason Harding

Views

4096

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

Build Author

Terone Burgenheim

Views

6445

Build Author

Terone Burgenheim

Views

6445

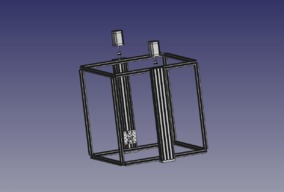

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Silverchris's Laser Cutter

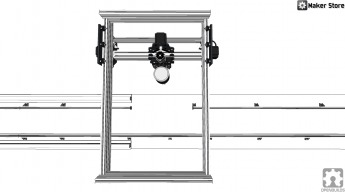

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Big-X Minimill

Minimill bundle, but with an extended X Axis

Build Author

Mark Carew

Views

17072

Build Author

Mark Carew

Views

17072

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

SCYBUCK

Views

5136

Build Author

SCYBUCK

Views

5136

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

RobFromLDMS

Views

5262

Build Author

RobFromLDMS

Views

5262

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Build Author

Vin1027

Views

7348

Build Author

Vin1027

Views

7348

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

John's Sphinx

1000mm x 750mm C-Beam Sphinx, running on Grbl

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

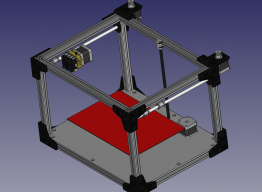

All Metal - CoreXY Motion

Stacked CoreXY Motion System using only Openbuilds components

1250x1000 Build

A new design of my based on a couple different machines I have seen both on openbuilds and youtube. In the end will have a and X/Y workspace of 1250mm x 1000mm and a Z axis range of about 200mm.

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

Ox cnc improvements chain driven

Just ox cnc experiment

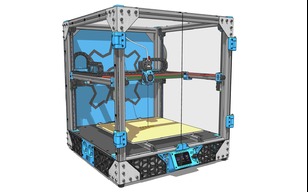

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

K40 upgrades

Cheap chinese K40 laser upgrades, including 60x30cm working area, MKS or SKR controllerboard (smoothieware or marlin, not yet decided.) Light, psu and a bit more :)

Build Author

Edgar Mata

Views

31611

Build Author

Edgar Mata

Views

31611

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

Build Author

Jasont

Views

4304

Build Author

Jasont

Views

4304

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Sigifredo Cruz Rojas

Views

4082

Build Author

Sigifredo Cruz Rojas

Views

4082

ALl included interface

I have not too much space and need a portable solution, and tired of cleaning the electronics I decide to put everything inside a box and this is the result.

Gauthali V2.0 DIY 3D printer

This is based on core XY kinematics. First of all, we designed a CAD model. Most of the required parts are designed by us in solidworks software, and some parts are downloaded from a web platform ‘grabcad’. After that we assembled those parts and inspected them in solidworks. The designed CAD models are frame of 470mmX392mmX545mm SBR linear guide rod, linear guide holder, lead screw, motor mounts, pulley, bed mount, idler block, timing belt clamper.

Build Author

David E. Flores E.

Views

3384

Build Author

David E. Flores E.

Views

3384

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Pen Plotter

All metal A3 CoreXY pen plotter

Build Author

hbtousa

Views

2314

Build Author

hbtousa

Views

2314

Six_Axis Camera Slider

X is 1000mm, Y is 1500 mm, Z is 1000mm. It Rotates 360 degrees and Tilt also can move 360 degrees. I also have a motor that controls the focus of the camera.

Build Author

mirage335

Views

12000

Build Author

mirage335

Views

12000

FlexReplicator

Multi-tool 3D printer, laser cutter, and CNC mill.

Build Author

Christer Langley

Views

9456

Build Author

Christer Langley

Views

9456

CNC-Solutions Build

My first Build with V-slot

Build Author

John J Talavera

Views

8482

Build Author

John J Talavera

Views

8482

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

DoubleX

This is a Dual X-axis platform.

Build Author

Richard Bugland

Views

9000

Build Author

Richard Bugland

Views

9000

Heavy Inexpensive CNC

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

CNC CARDBOARD BOX CUTTER

Just an easy build .... uncomplicated.... simple tools .... but hoping for a good result!

CoreXZ

I am building a H bot style printer so this design will not be finished any more than it is.

Mendal Max 1.5 EX2 - a part of this, a part of that.

I like this design a lot. It's very stable, very strong and with the EX2 enhancements, it prints like a champ.

Genesis XZ

CoreXZ implementation on 3d printer using Openbuild and RobotDigg parts.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

First Ooznest OX

The ooznest OX CNC Machine is based on the OX CNC Machine designed by Mark Carew of Openbuilds, and incorporates many upgrades from the Openbuilds community. Mark Carew based the OX on the Routy, which was in turn based on the Shapeoko

Cancelled - Modified OX CNC for Mitre Cutting (Picture Framing)

Creating a CNC mitre (45°) cutter, for picture frame cutting. Starting with an OX, but inverting various parts and adding a material table, with a stepper-controlled measuring guide.

Delta Bot: Improved DIY 3D Printer

Build the efficient and reliable all metal structure 3D Printer. Improved significantly with new concepts for printers. Great quality and up to 400 mm/s print speed (very fast). Built with heated bed, hybrid bowden suspended extruder, and counterweight (tested printing 21 hours straight with no motors hot). Optional smart controller for computerless printing. Print any kind of thermoplastic.

core xy smoothie

i had som left over parts and i dit like to test the corexy control so this is wat i came up with. sorry bad englich.

Build Author

Sonny Lowe

Views

10866

Build Author

Sonny Lowe

Views

10866

Folger-Tech Y-Carriage

This a redesign of the Folger-Tech Y-Carriage using the Solid V-Wheels, Ball Bearings, the V-Slot Rail System.

The Ox That Wood

This is my story about my need for a CNC router on a budget that wound up in the $5K range !!! but I have a good belt drive Ox

Idea for any axis support and Drive

Just an idea right now but will attempt a prototype in the near future. Not sure if this has been tried before or not.....

My first build: a other OX CNC

I love to build things. I decided to build a CNC machine to help me build more things! I had a lot of fun and I learn a lot of thing in the process of building this machine. p.s. my primary language is french not english. Forgive me if I made some mistake.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

D-Bot CoreXY printer

A CoreXY D-Bot 3d printer using gantries as wheel-carriages.

3D printer inspired by the Bukito

I have been working on this project for something like 3 years on and off, sometimes leaving it for a few months. Now I really want to finish it. For me, the mechanical part was the easy (though long) part because I get to use about 17 CNC machines and MasterCAM and I am a machinist. The hard part is the electronics part. Had a few problems getting Windows to communicate to the X5 Mini via the USB cable but found something on the Smoothie forum and got the machine moving.

BrandoneOuX

I'm Brandoneous; hence, the BrandoneOuX, a cartesian CNC build. Large format (1000mm x 1000mm) but beefed-up to solidly augment the ability to cut Aluminum in addition to wood and other solid materials. As I am currently living in a rented apartment for an out-of-state job, my secondary challenge is to build a sound dampening enclosure that will function as a torsion box base, a sound dampening enclosure, and a dust containment system. Easy, right? Well, we'll see... Join my journey

Build Author

Asaku

Views

9661

Build Author

Asaku

Views

9661

mBOX

Hi! This build is, or at least should be, a multipurpose box (mBOX). Due to limited space I want to build something that can serve multiple purposes such as 3d printing, 3d scan, plexiglass cutting and hopefully some milling too (both wood and metal). Switching between modes should involve switching heads and worksurface (change heatbed with a wood platform and viceversa). (for the scan part I'm thinking of integrating this opensource project into the frame: http://www.freelss.org/ )

Build Author

Martin Bogomolni

Views

12289

Build Author

Martin Bogomolni

Views

12289

Delta-Six ( Jerry426 variant )

Building a Delta-6 variant, using recycled parts from a WolfStock Delta printer.

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Lead screw printer

High quality e3d parts with a minimalist design

Build Author

McAdam

Views

3742

Build Author

McAdam

Views

3742

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Robert Huxford

Views

4000

Build Author

Robert Huxford

Views

4000

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7521

Build Author

Matt Barile

Views

7521

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

islahcnc

Views

4463

Build Author

islahcnc

Views

4463

islahcnc&design

I will post soon some more details.

C beam xl

I would recommend this challenge to any woodworker looking for something new.

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

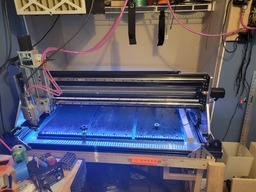

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

Karan Singh Sisodia

Views

8913

Build Author

Karan Singh Sisodia

Views

8913

CNC Laser

CoreXY based CNC Laser machine.

D-Bot Version B

D-Bot with a Replicate controller.