Build List

-

Active Filters:

t

Build Author

Jose A. Molina

Views

6946

Build Author

Jose A. Molina

Views

6946

Remote Controlled Robot Spider(Teaching Tool)

This Project is meant to teach introductory robotics and arduino styled micro-controllers to HS and MS students.

Build Author

Simon Rafferty

Views

7523

Build Author

Simon Rafferty

Views

7523

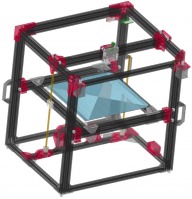

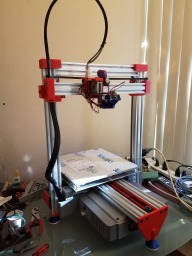

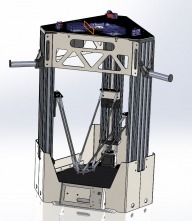

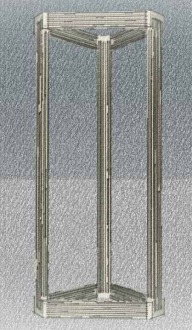

Rigid Delta

A Rigid Delta Printer using C-Beam screw actuators

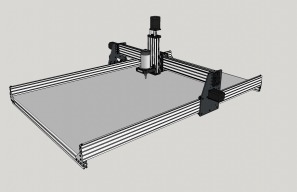

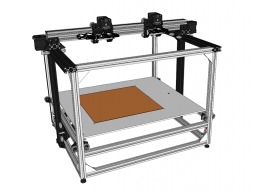

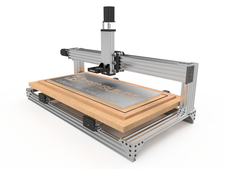

Schematix OX metal build

OX metal build from an noob

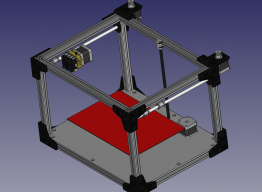

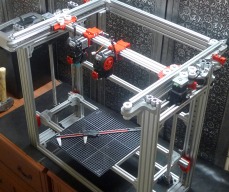

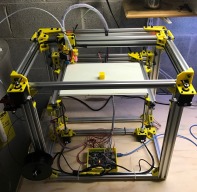

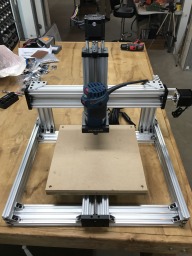

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Build Author

Krishnakumar

Views

8633

Build Author

Krishnakumar

Views

8633

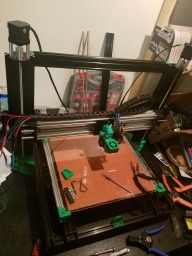

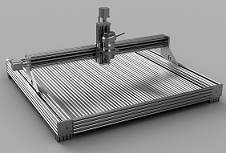

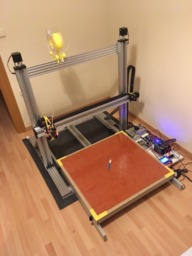

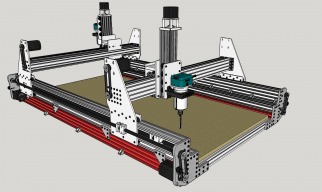

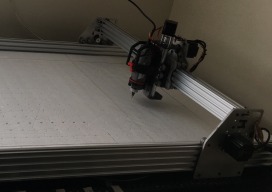

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

Build Author

Jose A. Molina

Views

6913

Build Author

Jose A. Molina

Views

6913

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

AK-Creation

Views

14850

Build Author

AK-Creation

Views

14850

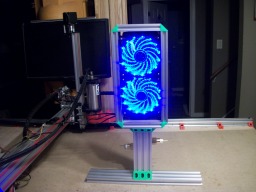

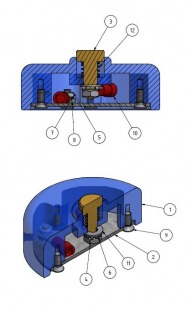

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Spindle cooling setup

Cooling system for water cooled spindle.

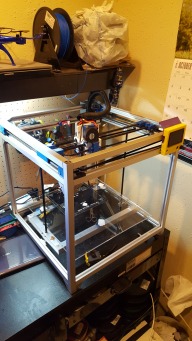

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

crystaldragon141

Views

6532

Build Author

crystaldragon141

Views

6532

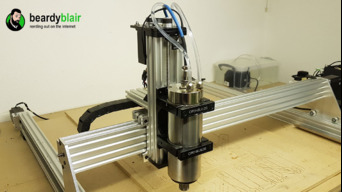

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

Build Author

beardyblair

Views

25236

Build Author

beardyblair

Views

25236

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

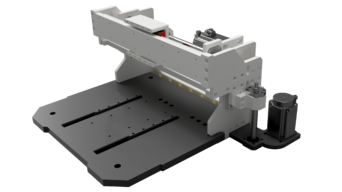

C-Beam Machine XL

Overview of my experience building the C-Beam Machine XL from OpenBuilds, along with updates as I move along and get it going. My application is for creating plates needed for lab functions, 19 rack bay covers, and whatever else arises.

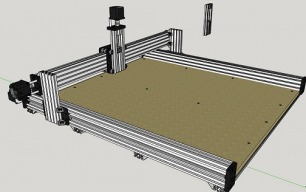

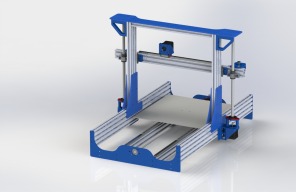

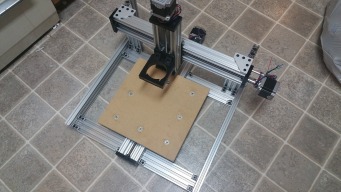

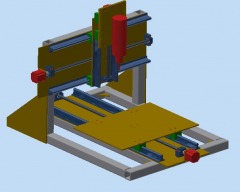

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

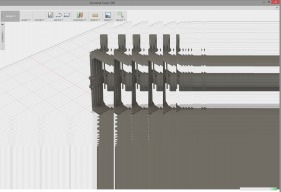

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

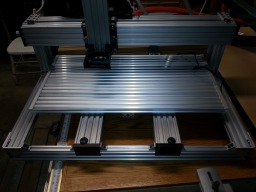

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Ooznest OX, Workbench, & Folding Table

An OX based unit with innovation surrounding it -- 9 drawers, workbench, folding CNC table, & portability.

laser gantry use mini v end block my own design

i always make laser cutting machine, but when i see openbuilds, this can make more cheap gantry for make laser cutting.

Build Author

Power Playground

Views

4802

Build Author

Power Playground

Views

4802

PowerBot

This is my own modified version of the D-Bot printer. I wanted to spec this printer to be able to print exotic materials at high accuracy with little to no compromises and maximum reliability.

C-Machine

MY experience as a first time introduction to the CNC world!

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

delta 3d printer kit

HE3D K200 kit build

Another 3D Printer using OpenBuilds Hardware only

A light 3D printer made of OpenBuilds hardware only

Schematix Ox-Metal Build

A build of Schematix's Ox-Metal design, with a 0.8kw watercooled spindle.

Build Author

sgspenceley

Views

8845

Build Author

sgspenceley

Views

8845

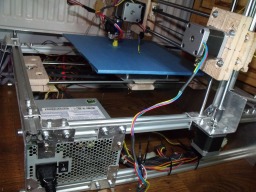

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Linear Rail for Dobot Magician

This is a simpel build of a Linear rail for the Dobot Magician.

Build Author

Ken376

Views

3708

Build Author

Ken376

Views

3708

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

Build Author

JP Warnke

Views

12755

Build Author

JP Warnke

Views

12755

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

dodgenet

Views

6536

Build Author

dodgenet

Views

6536

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Live D-bot build at MRRF 2017 (Mar 25-26)

I will be attending the 2017 Midwest RepRap Festival (MRRF) with a small team of printer enthusiasts with a goal to fully assemble a Core-XY D-bot onsite during the event. This is our first attempt at building a D-bot and we will be learning things as we go. Our hope is to have the entire machine assembled, wired, and functional (at least to the setup and testing phase) before the end of the show. Please attend and watch us in person or visit our feed channel during/after the event.

Build Author

mikev

Views

8543

Build Author

mikev

Views

8543

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

Anthony Bolgar

Views

5701

Build Author

Anthony Bolgar

Views

5701

Air assist/fume collector for Diode Laser Engraver

This is a work in progress

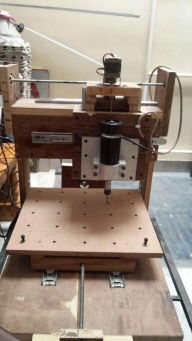

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

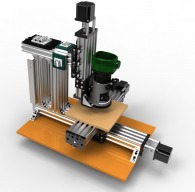

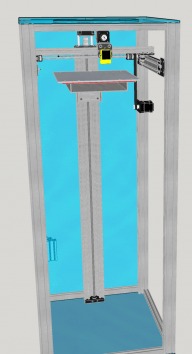

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

TouchPadKing

Views

5072

Build Author

TouchPadKing

Views

5072

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Large Delta Printer made from scrap 80/20

This printer will leverage scrap pieces around the shop to fulfill a single print's needs. It will use a combination of 80/20, OpenBuilds, and 3D printed parts.

Build Author

signzonepr

Views

12989

Build Author

signzonepr

Views

12989

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Build Author

Thair.nl

Views

3759

Build Author

Thair.nl

Views

3759

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Old Faithful...FDM/CNC machine

I've owned some pretty unreliable printers, and I'll leave it at that... This design comes from the need to have a 3D printer that is reliable, period. I didn't have the money for a several thousand dollar 3d printer with an equivalent build area so that was out of the question. Plus as a fledgling Engineer, I really wanted to blood myself on a project. And that's how Old Faithful came to be. A simple, reliable, rigid, durable machine. Made by me :) Also, it'll be tough enough for light CNC.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Build Author

Linkreincarnate

Views

3103

Build Author

Linkreincarnate

Views

3103

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

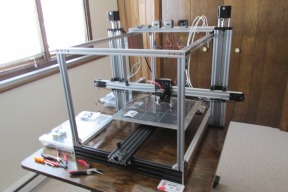

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

Build Author

Kyo

Views

6491

Build Author

Kyo

Views

6491

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8491

Build Author

taratata2016

Views

8491

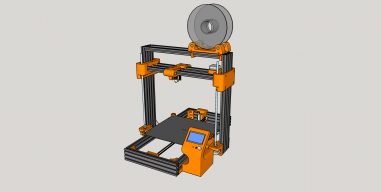

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Limine3D

Views

8514

Build Author

Limine3D

Views

8514

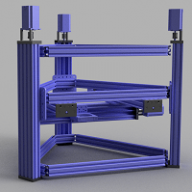

M3D Squared

A cartesian build with a build dimension of 200x200x750mm. I will be using a dual extruder, heated build plate, and a screw drive for the z axis.

Yet another Sphinx

Here's my Sphinx with a few slight modifications.

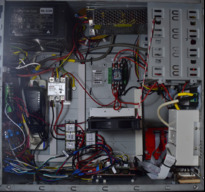

Epoxy dispenser, to apply non-conductive epoxy to electronic board.

Epoxy dispenser, 2nd one, first one works great. Uses HMI to allow for operator to pull up files for different jobs. 9 prox sensors, Eot and home on all 3 axis. High quality nema23 motors with intergrated drives from applied motion. Uses programmable router for drives.

Clock repair stand

Open source clock movement stand

Wifi'not

A simple made hideaway for ugly electronics

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

My 2nd cnc build

My new build to upgrade from my worn out shapeoko

Build Author

Makerparts

Views

7654

Build Author

Makerparts

Views

7654

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Greg Lampman

Views

9168

Build Author

Greg Lampman

Views

9168

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

Tom Dirriwachter

Views

7318

Build Author

Tom Dirriwachter

Views

7318

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Dmknerr

Views

5171

Build Author

Dmknerr

Views

5171

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

Chetan PM

Views

3772

Build Author

Chetan PM

Views

3772

Composer

Gantry style rigid build

A work in progress

One of my first projects might be cutting proper plates.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

Robert Huxford

Views

3935

Build Author

Robert Huxford

Views

3935

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

Build Author

Matt Barile

Views

7422

Build Author

Matt Barile

Views

7422

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Double trolley X and Z belt training

Total belt drive GT2

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9107

Build Author

J-Wahl Dezign

Views

9107

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

3D Meister

Views

5451

Build Author

3D Meister

Views

5451

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

C-Beam Machine upgrade to 1000mm x 1000mm

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

Build Author

Rich Bowen

Views

3815

Build Author

Rich Bowen

Views

3815

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Robert E. Nee

Views

17301

Build Author

Robert E. Nee

Views

17301

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

Build Author

Peter Van Der Walt

Views

7352

Build Author

Peter Van Der Walt

Views

7352

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

recoush

Views

9166

Build Author

recoush

Views

9166

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7163

Build Author

Jonathon Duerig

Views

7163

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

nschreiber0813

Views

5442

Build Author

nschreiber0813

Views

5442

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

THE LINK

Views

5045

Build Author

THE LINK

Views

5045

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Tomas F Uribe

Views

5305

Build Author

Tomas F Uribe

Views

5305

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hisha

Views

4965

Build Author

Hisha

Views

4965

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Huub65

Views

9192

Build Author

Huub65

Views

9192

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

evgeny156

Views

7289

Build Author

evgeny156

Views

7289

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Jens Grabner

Views

4085

Build Author

Jens Grabner

Views

4085

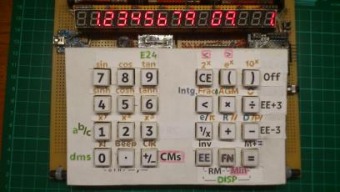

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

Extendable Mini Mill

Another MiniMill, different to the OpenBuilds version and potentially more flexible because of the design.

Build Author

Fabio Orsi

Views

6905

Build Author

Fabio Orsi

Views

6905

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Sandy3D wall mounted 1000 mm x 1000 mm C Beam Mill

I am attempting to mount The C-Beam Machine XLarge on the wall and have it look like a piece of art and be totally functional as this will be in our livingroom.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

megashub

Views

24089

Build Author

megashub

Views

24089

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Karan Singh Sisodia

Views

6253

Build Author

Karan Singh Sisodia

Views

6253

My Home made CNC

Home Made CNC Router from Scrape

Build Author

islahcnc

Views

4420

Build Author

islahcnc

Views

4420

islahcnc&design

I will post soon some more details.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.