Build List

-

Active Filters:

l

Build Author

Builder+Bob

Views

3627

Build Author

Builder+Bob

Views

3627

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Ken376

Views

3587

Build Author

Ken376

Views

3587

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

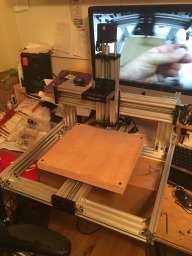

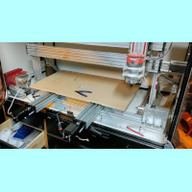

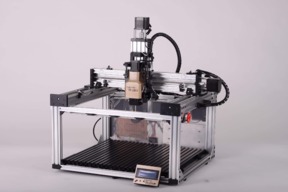

My 1st C-Beam Router

Pretty happy with the build, had some difficulty with the software loading up the settings due to me using the wrong com.

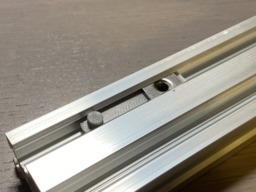

T Nut Holder for V Slot

This is a T Nut Holder for OpenBuilds V Slot System. Useful when you want to keep t nuts in place, for example when you're mounting something vertically.

Reworked Sepcraft 420 CK

Its alive !

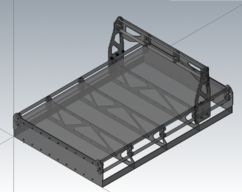

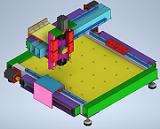

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

Hidro669

Views

3553

Build Author

Hidro669

Views

3553

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

h3rb

Views

3551

Build Author

h3rb

Views

3551

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Build Author

McAdam

Views

3549

Build Author

McAdam

Views

3549

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Clock repair stand

Open source clock movement stand

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

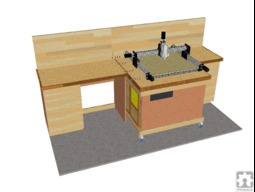

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Indoor Drumline Props

Triangular Towers

Build Author

Braden Masse

Views

3474

Build Author

Braden Masse

Views

3474

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

Denford CNC Resurrection

Denford CNC Mill Update

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

Damian V-SLOT Poland

Views

3421

Build Author

Damian V-SLOT Poland

Views

3421

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Build Author

bpatterson42

Views

3409

Build Author

bpatterson42

Views

3409

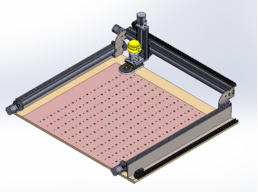

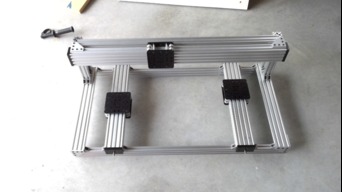

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

Calotype

Views

3390

Build Author

Calotype

Views

3390

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Remote Toiler Flusher!

This project provides an easy method for my granddaughter to use the facilities in the smallest room of the house! The toilet cistern is located in the garage and was originally manually activated by a pushbutton connected via a cable. The location of the pushbutton - combined with the stiffness of the mechanism made it tricky for her to use. This project provides a solution to the problem.

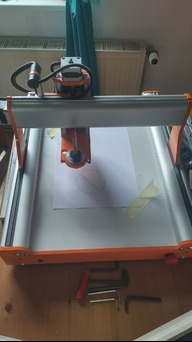

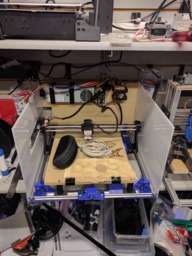

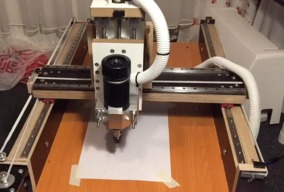

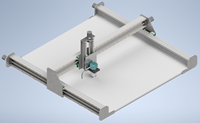

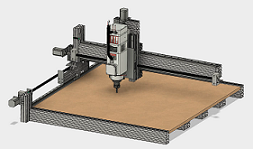

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Phil's MiniMill

A quick little mini mill build

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

Build Author

Daniel.korneliussen

Views

3349

Build Author

Daniel.korneliussen

Views

3349

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Router for speargun hobby

First router build for speargun fabrication

Plate 'o CBEAM

I'm starting with the c-beam bundle, and I hope to end up with a pretty useful little platemaker/shallow relief carver. I'm hoping to discover how accurate and efficient it can be.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

MOVABLE ART TO SCREEN WALL-MOUNTED TV

This project produced a movable framed canvas to cover a wall-mounted flat-screen TV when not being viewed, which at the touch of of a switch moves down below the TV and sound bar. The same switch is used afterwards to return the artwork up to cover the TV again. Photo shows mechanism without the canvas frame. See other photos.

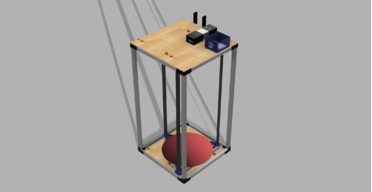

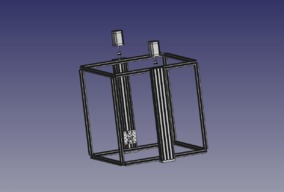

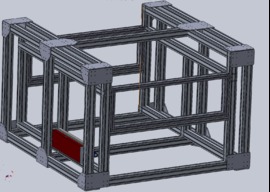

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Edge Carve MK1

I have created a video showing the Edger Carve features https://www.youtube.com/watch?v=v5mV_6vyxAA&t=3s

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

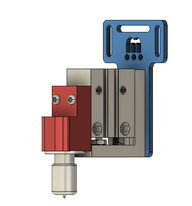

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

BCulbertson

Views

3168

Build Author

BCulbertson

Views

3168

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Model train lift - scale HO

This build is about a model train lift in a secure and dust free storage. It is a roll on/roll off concept for a model train layout.

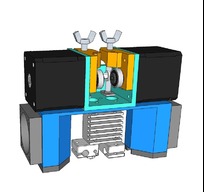

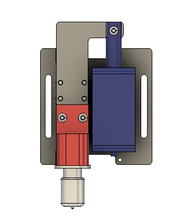

Dual Direct Drive Extruder

a dual extruder build using direct drive for flexible filaments

Build Author

Stan Howe

Views

3139

Build Author

Stan Howe

Views

3139

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

Build Author

Genetoys

Views

3139

Build Author

Genetoys

Views

3139

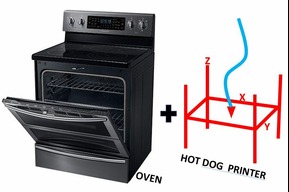

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

K-Cup Sealer

This is a K-Cup sealer i constructed does a fine job

Build Author

cnc-trucker

Views

3129

Build Author

cnc-trucker

Views

3129

Arduino Mega to EMC2 (LinuxCNC) Plasma Table Conversion

This is a story about a guy who started with a $25 set of plans, and through 4 iterations/ rebuilds, ended up with a professional quality CNC plasma table capable of cutting anything steel up to 2 inches thick.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Build Author

Anthony Castelluci

Views

3121

Build Author

Anthony Castelluci

Views

3121

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Gauss Probe Machine

Standard build with high Z using a Gauss probe instead of a router.

Angle grinder converted into electric drill

How to convert an angle grinder into an electric drill? Remove the angle grinder, leaving only one main motor, and then find a suitable intermediate roller with a point drill to assemble it.

Build Author

hbtousa

Views

3076

Build Author

hbtousa

Views

3076

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Mammoth (Delta printer)

Massive Delta printer with a print area of 25 Inches (634mm).

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Neil Scott

Views

2996

Build Author

Neil Scott

Views

2996

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

Linkreincarnate

Views

2983

Build Author

Linkreincarnate

Views

2983

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Project Infinity co2 laser

1m x 1.8m 60w co2 laser build.

Build Author

David Hartkop

Views

2884

Build Author

David Hartkop

Views

2884

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

Build Author

Bucky Wootmaster

Views

2854

Build Author

Bucky Wootmaster

Views

2854

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

C-Machine

MY experience as a first time introduction to the CNC world!

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

Gary Caruso

Views

2801

Build Author

Gary Caruso

Views

2801

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Something a Tad different

Future CNC router kit design

CNC Cutter Knife

CNC knife cutter with loline blades

Build Author

mjenkins5720

Views

2778

Build Author

mjenkins5720

Views

2778

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Black Box/ Power supply brackets

This items are so cool that they need to be together, so I decided to create brackets that connect both pieces together

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Hevavy duty 1300mm x 1300mm laser cutter Ceramic tube Servo motors

Starting the next Laser build, Plan to complete within 60 days.

Large format laser

Large format laser build for Student use at my school as well as some personal use.

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

Build Author

Terone Burgenheim

Views

2662

Build Author

Terone Burgenheim

Views

2662

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

David E. Flores E.

Views

2611

Build Author

David E. Flores E.

Views

2611

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Pen Plotter

All metal A3 CoreXY pen plotter

Build Author

Sprags

Views

2533

Build Author

Sprags

Views

2533

C-Beam Kyo Sphinx 10060

More stuff here.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Ooznest workbee

This is my first build so I will let you know how I get on

Galvos

3d printable galvos

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Pneumatic cnc cutter with festo drive

CNC Glass cutter

Gluing frame for guitar tops and backs

I have built four of these frames. The first pictured I have been using for maybe a year or two and bought the clamps. The last three I have made I have built my own clamps with openbuild parts. I am still working on the design. At present I use wedges to apply pressure to the side of the wood and block. I am working on a cam system to apply pressure. I just bought 8mm screws with Knobs for quicker adjustment. I will update the build when I make these improvements.

OoozNest WorkBee

A Journey on the WorkBee Build...

An other Ox Metal Build AZ

Had left over parts from cnc plasma build.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Acro 1010 with 10 watt Laser

Built a 32"x40" ACRO Kit for my 10watt Endurance Laser. Put it in a stand alone clamshell cabinet, added a 340cfm 6" fan and variable speed switch for the fan. Using LIght Burn for my primary software. It seems to be work well.

Needle cutter for foamplates

Cutting Depron foam panels by an oscillating needle

MIT E-Vent | MIT Emergency Ventilator

Ventilator prototype based of OpenBuilds Stock parts

ricks workbee build

i had the ox build and wanted to do a more beeffer style so i went with a workbee style machine ..

Build Author

Yosmany325

Views

2254

Build Author

Yosmany325

Views

2254

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

Build Author

Bill325

Views

2194

Build Author

Bill325

Views

2194

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.