Build List

-

Active Filters:

nc

no xp cnc

This is my first cnc build, never used one before and don't know too much besides what i've read a little bit about them online. It's probably going to be about 31" y axis with hopefully around 4ft x axis, z height is still to be determined.

Build Author

Srđan Marković

Views

4022

Build Author

Srđan Marković

Views

4022

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

Build Author

theracermark

Views

4017

Build Author

theracermark

Views

4017

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Build Author

Jones

Views

3989

Build Author

Jones

Views

3989

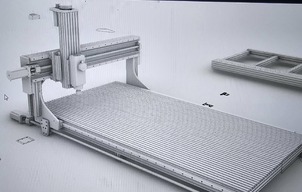

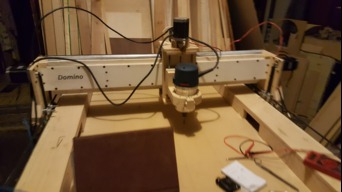

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

Build Author

Robert Huxford

Views

3978

Build Author

Robert Huxford

Views

3978

High Intensity Dive Light

Long duration , high intensity SCUBA dive light using Li-Po 18650 batteries and advanced circuitry.

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

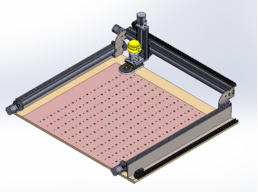

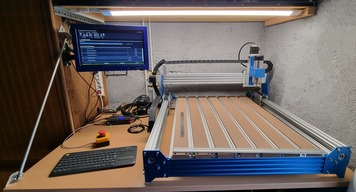

BKE Lead 1010 - First CNC Router

LEAD CNC

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

Rich Bowen

Views

3839

Build Author

Rich Bowen

Views

3839

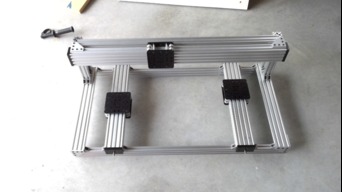

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Norwegian OX

This build is based of Ooznest 's OX CNC Mechanical kit (500x750) with a few mods if all goes as planned.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

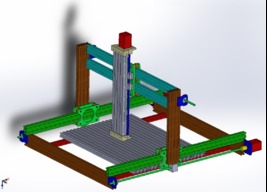

Mostly Printed Cartesian CNC

This is a build that is just getting started. Not all of the parts are ordered or printed as of 5/27/2018. Hopefully in the next few weeks all parts will be printed and most parts ordered.

Build Author

Builder+Bob

Views

3752

Build Author

Builder+Bob

Views

3752

Portable C-Beam

C-Beam Plate maker for My OX!

Build Author

Ken376

Views

3744

Build Author

Ken376

Views

3744

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

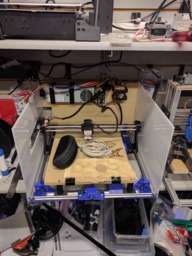

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

h3rb

Views

3736

Build Author

h3rb

Views

3736

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Denford CNC Resurrection

Denford CNC Mill Update

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

Braden Masse

Views

3642

Build Author

Braden Masse

Views

3642

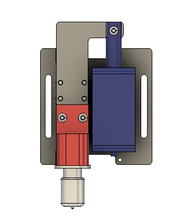

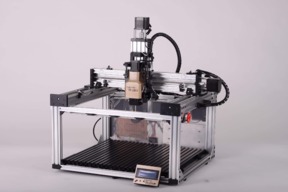

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

A work in progress

One of my first projects might be cutting proper plates.

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

bpatterson42

Views

3568

Build Author

bpatterson42

Views

3568

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Large C-Beam Sphinx style CNC Build

Started my build of a large Sphinx style cnc Router. I wanted one to handle the Dollar Tree Foam Board (DTFB) so I am making this to handle 2' X 3'. This is my first endeavor for a CNC so I am learning as I go but there is one thing for sure.

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

CNC machine 700x1200mm

I love to build things. I want a large cnc machine can do with little money. use Aduino .

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Stan Howe

Views

3338

Build Author

Stan Howe

Views

3338

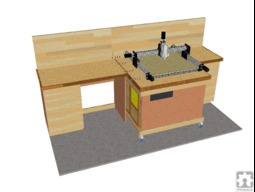

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Just Starting

My attempt at planning out my own CNC router

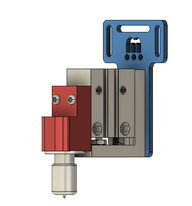

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Genetoys

Views

3312

Build Author

Genetoys

Views

3312

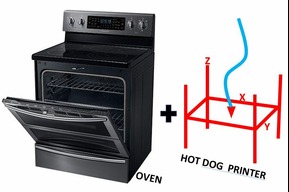

Oven Dog

Building a printer that can fit inside and operate at ~200 C oven temperatures

Build Author

Neil Scott

Views

3246

Build Author

Neil Scott

Views

3246

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Cnc Router 3000 x 1000 mm

In progress

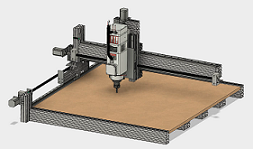

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Build Author

Linkreincarnate

Views

3131

Build Author

Linkreincarnate

Views

3131

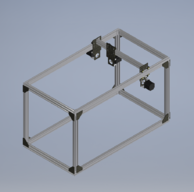

Amazon Special

I have parts that are apparently not suited to a cnc router or a 3d printer. I am still trying to figure out what to make out of what I have,

Build Author

Sir Bagels

Views

3114

Build Author

Sir Bagels

Views

3114

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Just Another CNC

I wanted to make my own unit. I enjoy building and was looking for a challenge.

Build Author

Gary Caruso

Views

3068

Build Author

Gary Caruso

Views

3068

OpenPull From CNC Kitchen.. attempt

This project is a Pull tester for material testing or structural testing with stress (force) data logging, I don't have plans for strain logging but that might be down the road.

Workbee with less irritations

My workbee build with some add ons

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

C-Machine

MY experience as a first time introduction to the CNC world!

SharkBits Holder

Get organized with the SharkBits Holder!

Build Author

David Hartkop

Views

3030

Build Author

David Hartkop

Views

3030

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

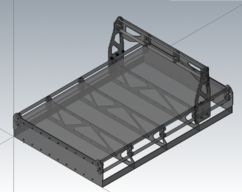

Repurposed Steel Table 4 x 8 Build

Repurposed Steel Table for CNC Router Build.

Build Author

Bucky Wootmaster

Views

2990

Build Author

Bucky Wootmaster

Views

2990

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

CNC Cutter Knife

CNC knife cutter with loline blades

Build Author

mjenkins5720

Views

2938

Build Author

mjenkins5720

Views

2938

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

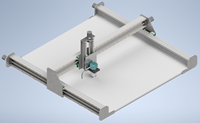

Something a Tad different

Future CNC router kit design

TFE2 CNC Build

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

first CNC build

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Build Author

Terone Burgenheim

Views

2825

Build Author

Terone Burgenheim

Views

2825

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Gizmo CNC

wanted large work area for laser etch/cuts more than spindle work.

Build Author

Sprags

Views

2734

Build Author

Sprags

Views

2734

C-Beam Kyo Sphinx 10060

More stuff here.

CNC Router Machine

CNC Router with working area 550*550*200

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Pneumatic cnc cutter with festo drive

CNC Glass cutter

An other Ox Metal Build AZ

Had left over parts from cnc plasma build.

OoozNest WorkBee

A Journey on the WorkBee Build...

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Build Author

Bill325

Views

2338

Build Author

Bill325

Views

2338

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

C beam Larger and Stronger

My first build based on the original C beam Sphinx. I’m not sure at this point what the final size will be. I have the parts from the c beam Sphinx and extra beams and lead screws to build up to 1000mm x 1000mm.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

Johnny Reich

Views

2051

Build Author

Johnny Reich

Views

2051

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

Build Author

Alexander_Bulgaria

Views

1672

Build Author

Alexander_Bulgaria

Views

1672

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

Build Author

robert christensen

Views

1491

Build Author

robert christensen

Views

1491

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed

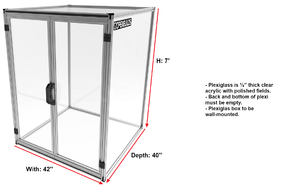

Plexi Panel

Plexi Panel to use for a vfd test enclosure. The box will be wall-mounted on plywood, so the back of the box is not necessary. - The bottom of the box is not necessary because the box will be fixed on concrete on the floor. On the door, I was thinking of putting 4 brackets instead of two. We'll have two 21” doors

Reducing leadscrew whip

The video demonstrates a practical device to reduce whip

Build Author

Alain JBT

Views

451

Build Author

Alain JBT

Views

451

First project Genmitsu ProVerxl 6060 Improved with OpenBuilds System

For a long time I had a project to buy a CNC, in time I have evaluated several possibilities. I chose the option of a pre-constructed and scalable machine according to my needs, with sufficient rigidity features to do work of average importance. The starting investment was important to take into account to allow changes from the open source domain.