CNC ROUTER BUILDS

Build Author

Kyo

Views

145455

Build Author

Kyo

Views

145455

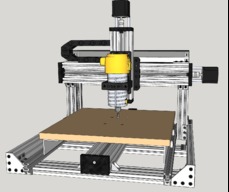

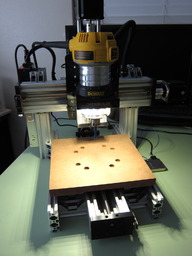

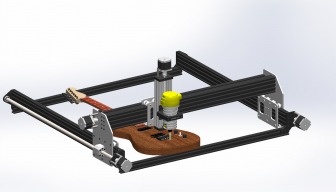

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Build Author

sgspenceley

Views

207986

Build Author

sgspenceley

Views

207986

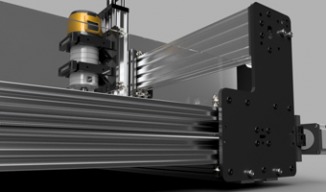

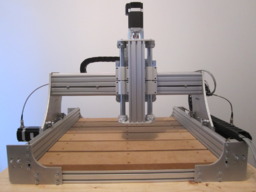

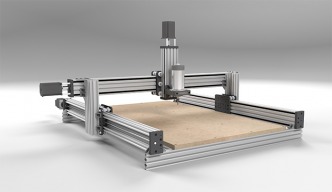

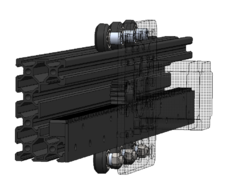

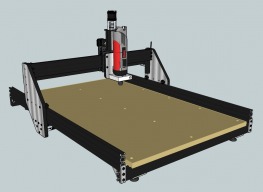

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

Build Author

Michael.M

Views

69252

Build Author

Michael.M

Views

69252

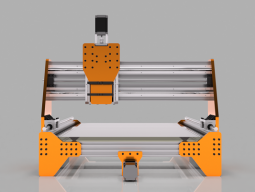

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

Build Author

blterry1

Views

19216

Build Author

blterry1

Views

19216

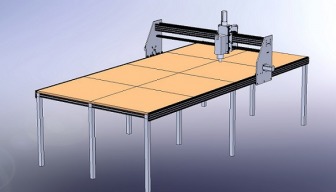

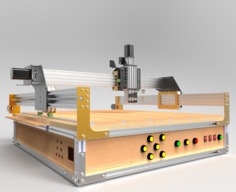

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

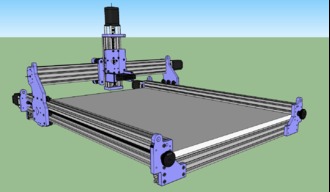

OX AI

This will be an Aluminum OX build. Plates and all design credit goes to Mark from open builds. I may add my own touches but mainly this is to see how Aluminum plates perform

Build Author

sebf34

Views

32111

Build Author

sebf34

Views

32111

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

Build Author

roadss

Views

26156

Build Author

roadss

Views

26156

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

Janis93

Views

15870

Build Author

Janis93

Views

15870

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Build Author

ahayden

Views

27539

Build Author

ahayden

Views

27539

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

Build Author

Michael.M

Views

45613

Build Author

Michael.M

Views

45613

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Build Author

Sword66

Views

14090

Build Author

Sword66

Views

14090

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

The Frog: CNC Router

Frog CNC Router. Inspired by OX and "Routy". 24"x36" active working area, approx. 3" usable Z motion.

Build Author

Robert Hummel

Views

25682

Build Author

Robert Hummel

Views

25682

Stinger V Micro Mill

While building my OX AI I found myself with left over v slot and thought to myself, what do I need that I can build using them? Well since I make a lot of my own PCB boards for projects I figured a micro PCB mill would fit the bill ;) With inspiration from the OX and OX AI I give you the Stinger V :)

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Build Author

Robert Bailey

Views

29465

Build Author

Robert Bailey

Views

29465

FRANKINATOR -- My CNC Router Built Around The C-Beam Rail

I started this build about 2 weeks after the c-beam hit the store. I purchased a single bundle and ordered a TinyG to run it. where I work I have Hardware, Software and Mechanical engineers and they all got sucked into my project. they want one to do prototyping at the office, once they see mine...

Build Author

alex_b

Views

17365

Build Author

alex_b

Views

17365

RONIN OX | The G10/Carbon Fiber Hogger

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.

Build Author

Glenn Weston

Views

18408

Build Author

Glenn Weston

Views

18408

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Joe Young

Views

15012

Build Author

Joe Young

Views

15012

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

spunks.cam

Design of a multifunctional CNC machine.

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

MyCNC(1000mm x 1500mm)

My CNC project

Build Author

Teflon4

Views

16002

Build Author

Teflon4

Views

16002

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

Dust Boot and Holddown in one

only 2 screws to hold down even bent sheet material and vaccum dust removal in one

Build Author

alex_b

Views

19199

Build Author

alex_b

Views

19199

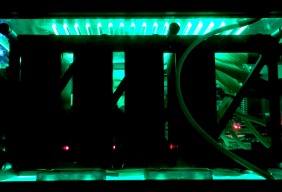

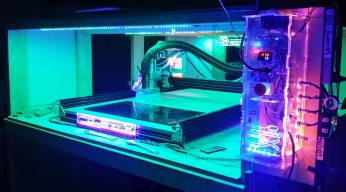

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

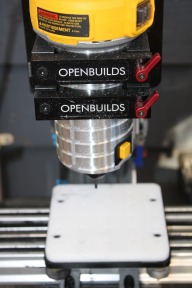

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Build Author

CharlieShimota

Views

16296

Build Author

CharlieShimota

Views

16296

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Build Author

Gooshpoo

Views

9411

Build Author

Gooshpoo

Views

9411

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

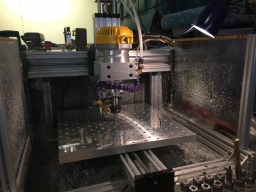

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Build Author

Rob Mahan

Views

13971

Build Author

Rob Mahan

Views

13971

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

MarkM_NJ

Views

20067

Build Author

MarkM_NJ

Views

20067

Spartacus Inspire

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

Build Author

Mike Campbell

Views

11246

Build Author

Mike Campbell

Views

11246

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Rick 2.0

Views

21502

Build Author

Rick 2.0

Views

21502

C-Beam Mini Mite

A small system with a big bite. Design achieves a good balance between machine size vs. build area, rigidity and ease of construction all while keeping build cost as low as possible.

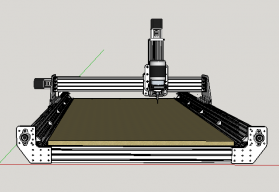

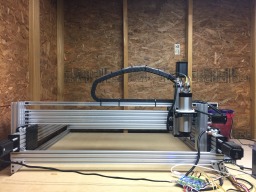

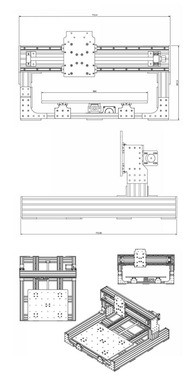

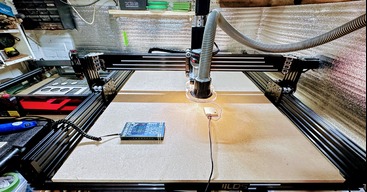

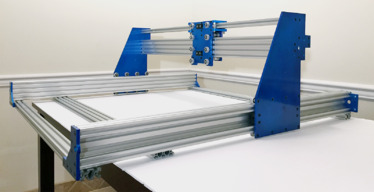

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

Build Author

Mark Carew

Views

75812

Build Author

Mark Carew

Views

75812

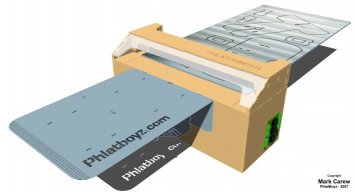

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Tool position setting Part II.

The method used for tool position setting is a matter of personal choice but this is what I do.

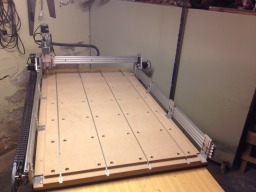

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

winand

Views

18082

Build Author

winand

Views

18082

YAOR (Yet Another Openbuilds Router)

Yet Another Openbuilds Router, my version :-)

Build Author

Rural

Views

26110

Build Author

Rural

Views

26110

OS OX

Mechanically, a scaled up OX build (1500x1500). Electronically, GRBL on an Arduino and a gShield. From a software perspective, the focus is on useable open source software tool chains.

Small Red OX

A small router for thin plate stock

Build Author

ymilord

Views

22340

Build Author

ymilord

Views

22340

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

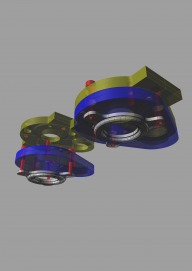

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

C-BEAM-GTC

Building a larger C-BEAM CNC Machine with no previous experience.

Build Author

Julius

Views

25567

Build Author

Julius

Views

25567

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Savvas

Views

19762

Build Author

Savvas

Views

19762

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

Gary Caruso

Views

25013

Build Author

Gary Caruso

Views

25013

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

Ballmasters 1605 1500x1000 ox cnc

Upgraded 1500x1000 Ox cnc to 1605 Ballscrews on the Y axis. along with the J-tech laser to do most things.

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

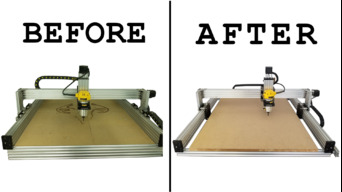

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

Build Author

Jacob Lotter

Views

27532

Build Author

Jacob Lotter

Views

27532

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Build Author

mytechno3d

Views

28407

Build Author

mytechno3d

Views

28407

Router / plasma cutting table ( Rack and pinion )

Heavy DIY plasma cutting table

Build Author

Ryan155

Views

14186

Build Author

Ryan155

Views

14186

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

Frank Del Favero

Views

9886

Build Author

Frank Del Favero

Views

9886

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Tool position setting Part III.

In this, the final part, I would like to introduce Machine Vision and show how it can be used, not only for tool position setting but also for resolving the triangle to calculate the G68 (local system rotated) for jobs which are not squarely placed on the work table.

Build Author

richthorn

Views

8297

Build Author

richthorn

Views

8297

Aluminum Ox

I have been looking for a good solid kit to build off of for some time and when I saw the Ox buildlog I knew I had to have one. Ordered most of the pieces from Open Builds and started planning. Had a nice gentleman named Chris cut the required plates from 6061 aluminum for me (he sells them on eBay now if you're interested) and got to work.

Build Author

Serge E.

Views

61190

Build Author

Serge E.

Views

61190

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Florida Ox 2x4 Area 51 CNC Parts Original Build

2x4 Ox with Vac table

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

Build Author

M^3

Views

22120

Build Author

M^3

Views

22120

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

OX Tale

1000mm x 750mm OX with some planned enhancements. My first venture into CNC.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

Build Author

Rakmup

Views

41502

Build Author

Rakmup

Views

41502

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

GrOX (OX based router)

1000mm x 1500mm OX router using Openbuilds parts and plates by Chris Laidlaw

Build Author

Sonny Lowe

Views

7050

Build Author

Sonny Lowe

Views

7050

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

Vertek CNC - 1000mm x 750mm Linear Rail on C Beam

C beam gantry with steel guide rails!

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

C-Beam to C-Beam XL Upgrade

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Build Author

Maxime Favre

Views

9569

Build Author

Maxime Favre

Views

9569

SmoothiebrainZ CBeam Machine

Modded Plate maker with: Smoothiebrainz board and DQ542MA SN04 Endstops Modded Z axis Aluminium build plate and renforced Y axis Dust shoe

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Build Author

Rick Holder

Views

15493

Build Author

Rick Holder

Views

15493

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

JWhitten

Views

14217

Build Author

JWhitten

Views

14217

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Savvas

Views

14477

Build Author

Savvas

Views

14477

Halloumi CNC Machine - Acetal Plates

I built the original machine using plywood plates, and always intended to upgrade those parts to more durable ones. I decided to go with acetal as it's a lot easier to cut than aluminium. I used fusion 360 to model and rebuild the original machine. Once I have assembled everything and feel confident it all works I will release the plate designs here.

Build Author

dmasters

Views

8288

Build Author

dmasters

Views

8288

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Joerharris

Views

6601

Build Author

Joerharris

Views

6601

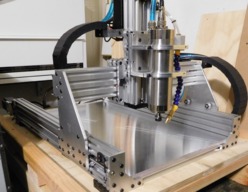

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Andre Cooke

Views

17720

Build Author

Andre Cooke

Views

17720

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

ShockingTops

Views

4542

Build Author

ShockingTops

Views

4542

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Michael.M

Views

9769

Build Author

Michael.M

Views

9769

Sphinx Evolution

Let me explain: About a year ago I was planning to build a CNC router of my own design. I started gathering components including the THK linear rails. I soon found out you pretty much need a CNC to build a CNC and this is when I decided to build my Sphinx machine. I've had these rails and some other parts sitting around so it's time I used them! I'm planning to incorporate linear rails and 1605 ballscrews into the Sphinx design. I really like the overall appearance of the Sphinx.

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

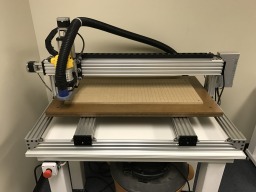

CNC Router Overhaul

This will be a complete overhaul of this router with some cool modifications.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

that-jim

Views

48142

Build Author

that-jim

Views

48142

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Fixed Gantry CNC Router

A fixed gantry router using OpenBuilds control and electronics.

Build Author

Scott Drake

Views

26962

Build Author

Scott Drake

Views

26962

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

My Lead 1010

This is a fully loaded Lead 1010 and located in a shed measuring 3 by 2.50 meters. Here i build my guiyats by hand and the help of my Openbuilds friend! Pure for hobby.

Build Author

BCulbertson

Views

5459

Build Author

BCulbertson

Views

5459

Lead 1515 with Upgrades

My upgraded OpenBuilds Lead 1515

Cheetah 1.1 CNC Router

I hope to have a working prototype built soon.

Build Author

Mark Carew

Views

14875

Build Author

Mark Carew

Views

14875

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

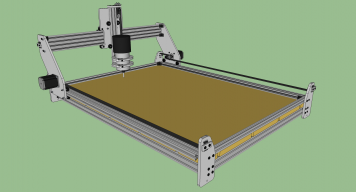

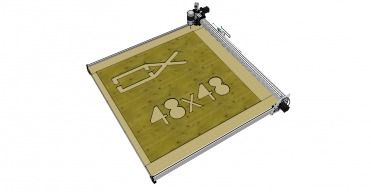

OpenBuilds OX 48x48 Aluminum

Variant on the OpenBuilds OX CNC Router, enlarged with 1500mm length beams for a cutting area of 48" x 48". Based on the original model, the larger of the two, with the addition of a third 20x60 beam on the gantry for strength. Estimated cost is around $1100, minus the router.

Ultimo

Ultimo is the ultimate multi tool for the person who's serious about prototyping new ideas. A Delta Robot frame supports 3d printing up to 450mm in diameter, a powerful CNC Mill, and 50 amp plasma cutter for processing steel plate. And that's just a start.....wait till you see some of the other attachments we are currently working on incorporating.

Router / Plasma Prototype Build

this is my first attempt at a CNC Table