Build List

-

Active Filters:

ar

Build Author

Nwrgordon

Views

15868

Build Author

Nwrgordon

Views

15868

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Build Author

Julius

Views

8184

Build Author

Julius

Views

8184

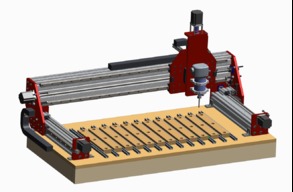

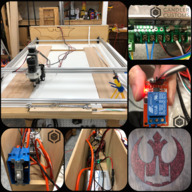

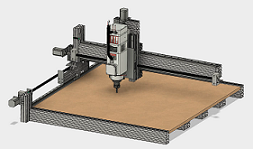

The "Hand" CNC (or OXCarve)

more to come, please follow along the journey!

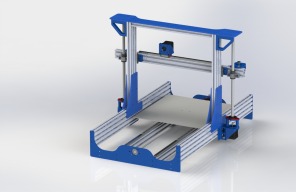

bertha

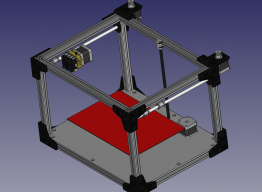

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Eddie's Build of Niko's (gianakop) Egg Painter

This is my build of Niko's (gianakop) Egg Painter. Egg decorating is something many Christians do for Easter Sunday and the Easter (Paschal) Season that follows. This will be my initial use for the build, but also with minimal modification to be able to write/paint on other round objects like Christmas ornaments, coffee mugs, etc. Many people also decorate eggs for purely secular reasons.

Gargoile reproduction C-Beam™ Machine - Plate Maker

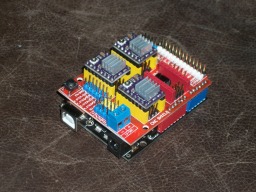

A stock C-Beam with a CNC shield with DRV8825's

Build Author

Keteland

Views

10688

Build Author

Keteland

Views

10688

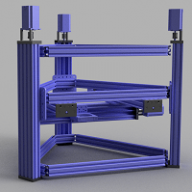

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

Matt Nelson

Views

12252

Build Author

Matt Nelson

Views

12252

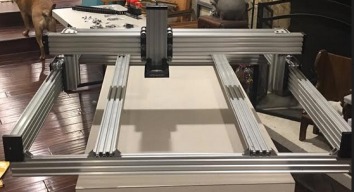

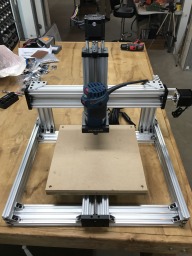

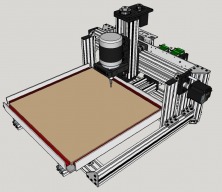

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

Build Author

Anthony Bolgar

Views

12000

Build Author

Anthony Bolgar

Views

12000

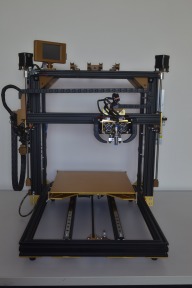

L'FOX - Large Format OX deriviative. Designed and built by Revision 13 Prototypes

This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. It is in the early stages, planning is complete, parts are ordered. Awaiting parts delivery to start build. Please not the BOM only covers parts from the OpenBuilds part store. I will be posting the other required items very shortly.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Build Author

eddyg

Views

4971

Build Author

eddyg

Views

4971

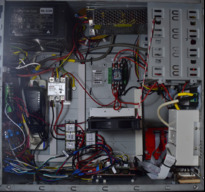

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Build Author

Metalguru

Views

14618

Build Author

Metalguru

Views

14618

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

Build Author

griso

Views

9236

Build Author

griso

Views

9236

3d nika

Over 840 parts. Of whom around 450 are screws and nuts, more than 100 parts are printed on a 3D printer, the frame consists of about 60 components. There is nearly 40 electrical components connected with tens of meters of wires, most of them sleeved.

Build Author

boubouexpress

Views

11464

Build Author

boubouexpress

Views

11464

3D Drucker sparkcube V1.1XL V-Slot™ Mini V Linear Actuator Bundle

sparkcube V1.1XL edit V-slot mini v linear

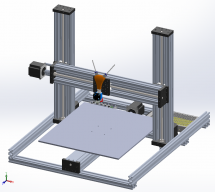

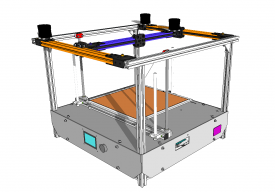

Dream to practical

This is my journey from a dream machine to a practical (for me) machine. This is a Cartesian style frame that can change tool heads quickly. The first version will have milling and 3D printing tool heads. Later on I'll add a drag knife tool head.

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game

CrOX Carbon Reinforced OX

Modified OX with carbon fiber reinforced X and Z axes. 1500mm Y, 1000mm X and 120mm Z clearence

Build Author

Dave420

Views

14478

Build Author

Dave420

Views

14478

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Cheap linear rail set up for z-axis

A easy to do cheap upgrade for the z axis

Schematix OX metal build

OX metal build from an noob

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

MOJO 3D

Fast, Large build area, CoreXY design

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Build Author

sgspenceley

Views

8910

Build Author

sgspenceley

Views

8910

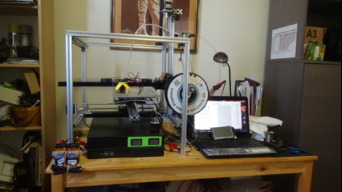

LinearRail - 3D Printer

I have re-purposed many of the parts from my Linear OX build. I'm using MGN 12 linear rails on all three axis, 5 start lead screws on the Z axis and I'm going to experiment with 5 start lead screw on the X axis. The frame plates are made from 1/8" laser cut mild steel, & open builds extrusion.

Build Author

Ken376

Views

3721

Build Author

Ken376

Views

3721

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Build Author

JP Warnke

Views

12788

Build Author

JP Warnke

Views

12788

Warnke CNC Router

A blend of modular aluminum and steel bracketry built to yield fine cuts in hardwood and aluminum. An open table with a shiftable pin-fixture concept will allow the operator to shift longer than Y-travel work-pieces, such as doors, along the Y-axis of the table. This machine has a 44" (X) by 24" (Y) by 8" (Z) travel with water cooled VFD spindle motor, t-slot ext work table, cable carriers, side guards n dual y drives. Total weight (w/base-stand) is about 600lbs.

Build Author

mikev

Views

8553

Build Author

mikev

Views

8553

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

Build Author

TouchPadKing

Views

5088

Build Author

TouchPadKing

Views

5088

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

signzonepr

Views

13009

Build Author

signzonepr

Views

13009

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Thair.nl

Views

3780

Build Author

Thair.nl

Views

3780

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

Build Author

Kyo

Views

6505

Build Author

Kyo

Views

6505

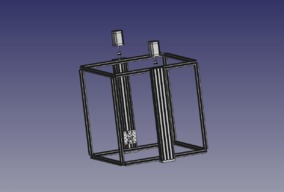

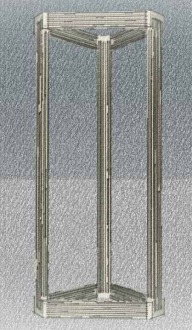

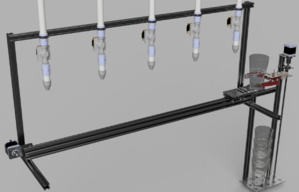

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

Build Author

taratata2016

Views

8540

Build Author

taratata2016

Views

8540

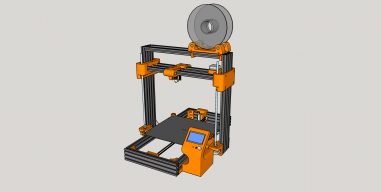

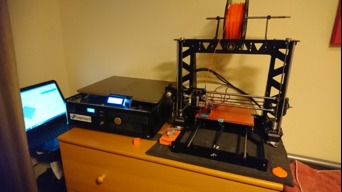

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

COMsulting

Views

10045

Build Author

COMsulting

Views

10045

1x1 Meter Laser Engraver

Building of a big open frame laser engraver.

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Build Author

Tom Dirriwachter

Views

7342

Build Author

Tom Dirriwachter

Views

7342

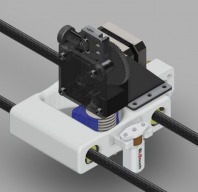

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

Dmknerr

Views

5189

Build Author

Dmknerr

Views

5189

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

Build Author

McAdam

Views

3716

Build Author

McAdam

Views

3716

Need a catchy name - enlarging CNC

The aim of this build is to have a CNC that can cut a FULL sheet of wood when I need it to, but also shrink down and cut smaller sheets the rest of the time. The prototype is based on an OX cnc but soon it will be completely custom using Openbuilds Parts

Build Author

Matt Barile

Views

7463

Build Author

Matt Barile

Views

7463

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

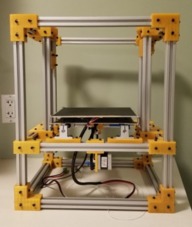

VoS

3D Printer based upon 3d printed parts and open builds componets

Build Author

J-Wahl Dezign

Views

9122

Build Author

J-Wahl Dezign

Views

9122

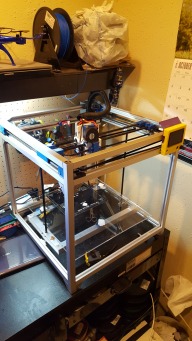

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

3D Meister

Views

5472

Build Author

3D Meister

Views

5472

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

STEAM Machine

Simple design with a large build volume - 450x450x450

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

recoush

Views

9211

Build Author

recoush

Views

9211

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

THE LINK

Views

5060

Build Author

THE LINK

Views

5060

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Tomas F Uribe

Views

5315

Build Author

Tomas F Uribe

Views

5315

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hisha

Views

4992

Build Author

Hisha

Views

4992

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

Huub65

Views

9226

Build Author

Huub65

Views

9226

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Jens Grabner

Views

4100

Build Author

Jens Grabner

Views

4100

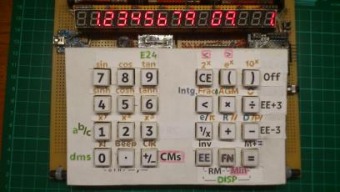

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

Build Author

Fabio Orsi

Views

6919

Build Author

Fabio Orsi

Views

6919

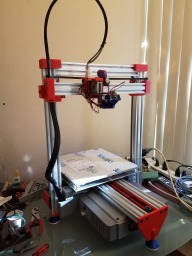

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Build Author

megashub

Views

24171

Build Author

megashub

Views

24171

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

islahcnc

Views

4429

Build Author

islahcnc

Views

4429

islahcnc&design

I will post soon some more details.

Build Author

JerryD

Views

5318

Build Author

JerryD

Views

5318

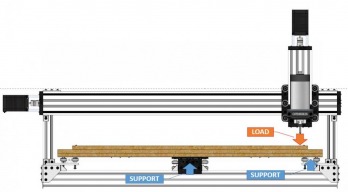

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Linear Rail derivative with ball screw

basic start to design of cnc machine

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Build Author

SecretSpy711

Views

22485

Build Author

SecretSpy711

Views

22485

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

TimVukman

Views

4277

Build Author

TimVukman

Views

4277

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

Kyo

Views

10040

Build Author

Kyo

Views

10040

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Build Author

ZacharyB

Views

5734

Build Author

ZacharyB

Views

5734

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

MidnightQuads

Views

3879

Build Author

MidnightQuads

Views

3879

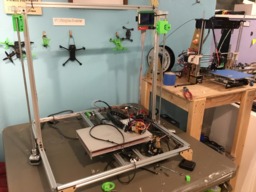

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12295

Build Author

GDanger117

Views

12295

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

8971

Build Author

Lindsey Lewis

Views

8971

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

George Motichka

Views

3764

Build Author

George Motichka

Views

3764

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

CandlerCustoms

Views

5485

Build Author

CandlerCustoms

Views

5485

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Build Author

Rodrigo Gonzalez

Views

3597

Build Author

Rodrigo Gonzalez

Views

3597

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

Nicademus

Views

9516

Build Author

Nicademus

Views

9516

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

TurfnSurf

Views

6197

Build Author

TurfnSurf

Views

6197

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

Build Author

JAC_101

Views

6050

Build Author

JAC_101

Views

6050

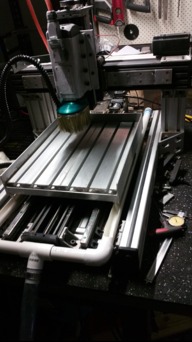

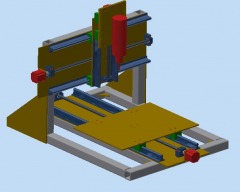

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

Connor Mckeown

Views

6372

Build Author

Connor Mckeown

Views

6372

My Prusa Build

The process from my bought printer, to a custom home built machine

Build Author

TurfnSurf

Views

7104

Build Author

TurfnSurf

Views

7104

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

Sprags

Views

2719

Build Author

Sprags

Views

2719

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Liam Dahler

Views

6493

Build Author

Liam Dahler

Views

6493

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Build Author

crnrstndes

Views

4192

Build Author

crnrstndes

Views

4192

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

Bucky Wootmaster

Views

2969

Build Author

Bucky Wootmaster

Views

2969

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Delta without vertices

As this is a build in progress, I will update it as I progress.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

jpjoshua

Views

13294

Build Author

jpjoshua

Views

13294

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Build Author

JerwanDavis

Views

6054

Build Author

JerwanDavis

Views

6054

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

Andreas Bockert

Views

11939

Build Author

Andreas Bockert

Views

11939

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Jones

Views

3959

Build Author

Jones

Views

3959

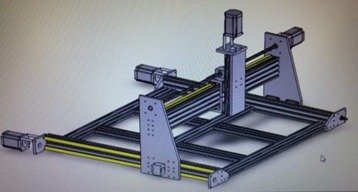

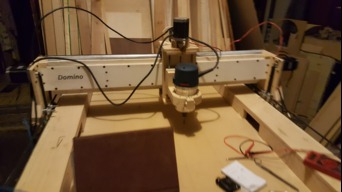

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.