Build List

-

Active Filters:

l

Build Author

TurfnSurf

Views

7077

Build Author

TurfnSurf

Views

7077

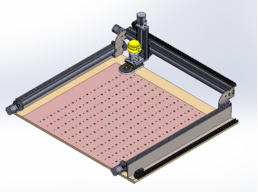

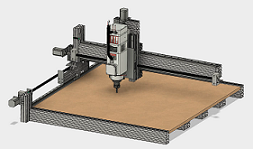

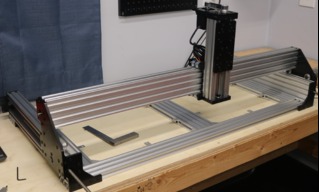

DIY C-Beam CNC

Theoretical Working Area: 360x360x75mm Actual Working Area: 300x300x75mm Will Update Later

Build Author

spark2

Views

5644

Build Author

spark2

Views

5644

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Sprags

Views

2704

Build Author

Sprags

Views

2704

C-Beam Kyo Sphinx 10060

More stuff here.

Build Author

Glenn Weston

Views

11321

Build Author

Glenn Weston

Views

11321

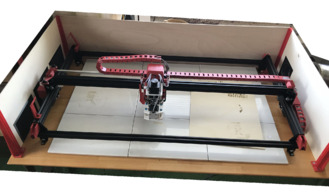

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

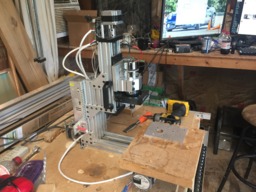

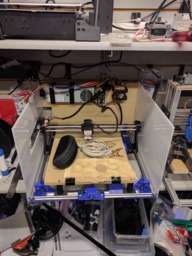

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Build Author

jz321

Views

4509

Build Author

jz321

Views

4509

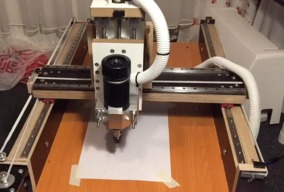

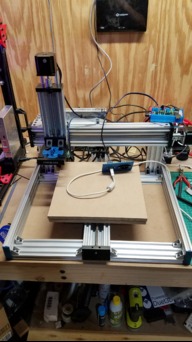

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Build Author

Liam Dahler

Views

6468

Build Author

Liam Dahler

Views

6468

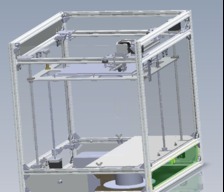

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

Blyn3D

Views

6341

Build Author

Blyn3D

Views

6341

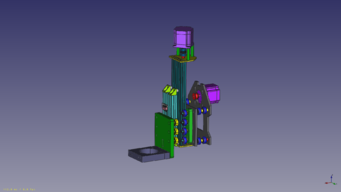

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

crnrstndes

Views

4166

Build Author

crnrstndes

Views

4166

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

BinaryConstruct

Views

10164

Build Author

BinaryConstruct

Views

10164

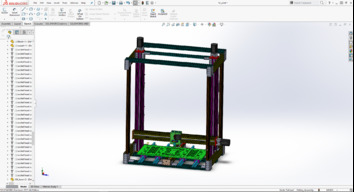

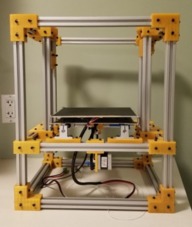

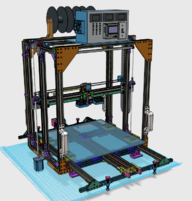

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Big CNC plasma cutter

more later

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Bucky Wootmaster

Views

2951

Build Author

Bucky Wootmaster

Views

2951

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Plasma CNC, 4'6" × 8'8" v0318

A plasma table able to cut 4'6" x 8'8" sheet. Low cost as possible.

Build Author

h3rb

Views

3711

Build Author

h3rb

Views

3711

TEVO Little Monster Marine Vinyl Removable Enclosure

Make a vinyl burrito ENCLOSURE for your TEVO LITTLE MONSTER for < $30 (<$20 if you don't have your vinyl shipped!)

Silverchris's Laser Cutter

Work in Progress of a laser cutter design. Based on the CoreXY build from https://makerstore.com.au

Build Author

obmilllivebuild

Views

5596

Build Author

obmilllivebuild

Views

5596

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Build Author

h3rb

Views

5651

Build Author

h3rb

Views

5651

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

pedrofernandez

Views

7876

Build Author

pedrofernandez

Views

7876

ACRO 20x20

The Acro Laser Machine Build

Build Author

John Bolduc

Views

5916

Build Author

John Bolduc

Views

5916

SG Duet Delta

This my version of a large no corners cut Delta.

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

ORCA Laser Build

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts. I modified the plates in an attempt to maximize the cutting area and I wanted a lightweight adjustable Z axis.

Something a Tad different

Future CNC router kit design

Desktop CNC

Approximately 910mm x 955mm x 82mm. There is 250mm available in the Z, but the gantry is only 82mm from the bed surface.

Build Author

Tommy Williamson

Views

6872

Build Author

Tommy Williamson

Views

6872

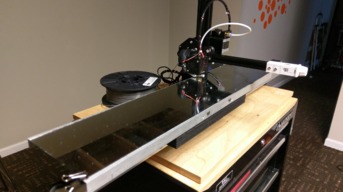

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

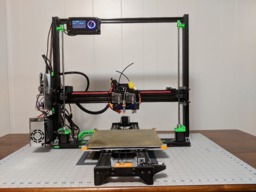

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

Kevr102

Views

5764

Build Author

Kevr102

Views

5764

Ooznest Ox CNC 1000 x 750

A few mods on my Ooznest supplied Ox cnc Encountered a few minor issues along the way but now all sorted.

Build Author

Hussein Dermay

Views

6435

Build Author

Hussein Dermay

Views

6435

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

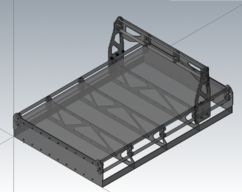

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Big-X Minimill

Minimill bundle, but with an extended X Axis

DPR-v2 full metal

pictures and mony doku see later

Delta without vertices

As this is a build in progress, I will update it as I progress.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

jpjoshua

Views

13196

Build Author

jpjoshua

Views

13196

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Build Author

ChrisViral

Views

7103

Build Author

ChrisViral

Views

7103

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

Mark Carew

Views

33580

Build Author

Mark Carew

Views

33580

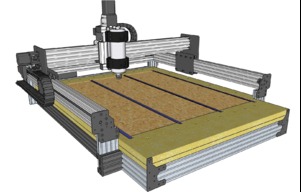

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

Build Author

Mark Carew

Views

77233

Build Author

Mark Carew

Views

77233

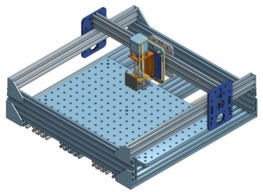

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Mark Carew

Views

27862

Build Author

Mark Carew

Views

27862

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

Makerparts Mpro Slider System

Makerparts.ca MPro Camera Slider System

Build Author

Todd Brous

Views

5563

Build Author

Todd Brous

Views

5563

Modified Acro with build plate, Z-axis and OPT Laser

Modified Acro for laser engraving. Extra height and and a sturdy build surface for part fixtures, custom mount plates, OPT Laser, and a Z-Axis.

V5- 2in1 ( 3dPrint+laser Engraving )

2in1 ( 3dPrint+laser Engraving )

LimpyCNC

Inpired by the OpenBuilds OX and PrintrBot Crawlbot. This is the LimpyCNC. It's still a work-in-progress. But it provides a 120x120cm work space without using up 150x150cm of garage space.

Build Author

Mark Carew

Views

25089

Build Author

Mark Carew

Views

25089

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

reef

Views

11868

Build Author

reef

Views

11868

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

Build Author

JerwanDavis

Views

6038

Build Author

JerwanDavis

Views

6038

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

Mark Carew

Views

16907

Build Author

Mark Carew

Views

16907

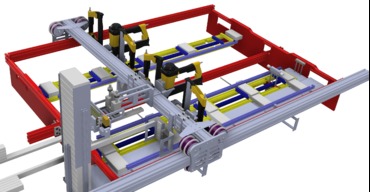

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Mark Carew

Views

17898

Build Author

Mark Carew

Views

17898

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Mark Rehorst

Views

10130

Build Author

Mark Rehorst

Views

10130

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Mark Carew

Views

18238

Build Author

Mark Carew

Views

18238

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Andreas Bockert

Views

11881

Build Author

Andreas Bockert

Views

11881

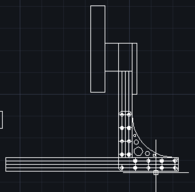

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Butterfly 3DP V 1.0

tronxy x3 like

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

stepper

Views

4504

Build Author

stepper

Views

4504

Touch screen macro imaging

This is a brief overview of the build of my macro imaging slide.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Galvos

3d printable galvos

Build Author

Hilleke

Views

7783

Build Author

Hilleke

Views

7783

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Stinger-Panting Images in the Air

Stinger displays images in the air by using a single column of LEDs. Special computer code converts graphics to pixels; then, the pixels are send to the strings of LEDs, which with the help of of the motor's fast movement the most colorful are displayed on thin air.

Build Author

mytechno3d

Views

15390

Build Author

mytechno3d

Views

15390

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

SCYBUCK

Views

5103

Build Author

SCYBUCK

Views

5103

KYO SPHINX a la' SCYBUCK

KYO SPHINX, CENTROID ACORN, GECKO 540, HALL EFFECT LIMIT SWITCHES, 2.2 KW, 24,000 RPM SPINDLE, WATER COOLED, 600 oz-in STEPPERS, INTENDED TO CUT ALUMINUM.

Build Author

Jones

Views

3943

Build Author

Jones

Views

3943

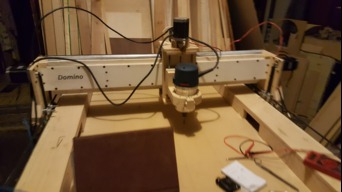

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Portable Sphinx 1050

Sphinx 1050 kit mounted to a Husky 46" x 24.5" mobile workbench.

Build Author

Luke Cunningham

Views

5863

Build Author

Luke Cunningham

Views

5863

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Rob Taylor

Views

10809

Build Author

Rob Taylor

Views

10809

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

26 x 26 x 45 3D Printer/Mill

Super tall 3D printer. All lead screw design.

Router for speargun hobby

First router build for speargun fabrication

Build Author

C-CNC

Views

15945

Build Author

C-CNC

Views

15945

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

WorkBee 1510 - First CNC Build

This build will go through the construction of a WorkBee 1510 kit from the OpenBuilds Part Store, all mechanical and electrical components were purchased from the store in late October 2018.

Build Author

Bob Darrow

Views

9978

Build Author

Bob Darrow

Views

9978

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Phil's MiniMill

A quick little mini mill build

Build Author

MrMojoRisin

Views

7522

Build Author

MrMojoRisin

Views

7522

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Build Author

pedrofernandez

Views

9967

Build Author

pedrofernandez

Views

9967

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Brice's CNC Router Build

I'm building a CNC router for a long time. Here's the result on this long journee. I tried to do my best with the basic tools I have. Don't hesitate to ask if you have questions.

Starting my build 2.8mx1.4m

Starting my cnc router, laser and plasma using aluminium 80x80

Build Author

Mark Carew

Views

6126

Build Author

Mark Carew

Views

6126

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

Mark Carew

Views

26727

Build Author

Mark Carew

Views

26727

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Kyo

Views

45432

Build Author

Kyo

Views

45432

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Build Author

Mark Carew

Views

8856

Build Author

Mark Carew

Views

8856

OpenBuilds PowerCase

A simple to assemble, super clean and safe PSU case solution that fits into the OpenBuilds wire management ecosystem

Build Author

deltajegga

Views

9817

Build Author

deltajegga

Views

9817

THE delta

probably as big as you'd want it...

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

RobFromLDMS

Views

5176

Build Author

RobFromLDMS

Views

5176

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

ECNCML (budget mashup)

This build summarizes my CNC milling and laser engraving machine conversion from a dimensional lumber frame and electrical mess to an all aluminum frame with a safe and well constructed (IMHO) control system with the resources I had available.

Build Author

James Evanko

Views

4759

Build Author

James Evanko

Views

4759

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

LaserShark300

300x300 belt drive laser etching/cutting platform. The design was borrowed from another's blog and customized to fit materials on-hand. Was a very fun project to assemble.

Open Builds C-Beam K-cup holder

Making use of c-beam I have had left over from projects.

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Black out Edition Workbee 1010

Thanks to all the Open Build elves that meticulously package and wrap all the little tiny parts and pieces. I have put in a request to get you people a raise..

Build Author

thinman

Views

8730

Build Author

thinman

Views

8730

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

Small Slot Cutter

A build to cut .008 inch slots into JB Weld.

Laser cutter

Full aluminium profiles construction. Synrad 50w CO2 laser. Ruida controller. Yaskawa servo motors

Build Author

joetemus

Views

6761

Build Author

joetemus

Views

6761

Shapeoko 2 Z-Axis Upgrade

This is a major redesign to the Z-axis of an otherwise stock Shapeoko 2.

My new wood mill

First and foremost, I want to create accurate parts for my model aircraft. In second line I am interested in the control and electronics of the milling machine. If you are interested in drawings and the parts list, feel free to contact me.