Build List

-

Active Filters:

r

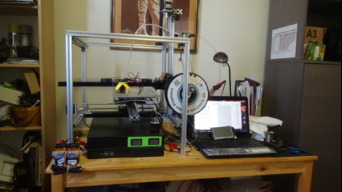

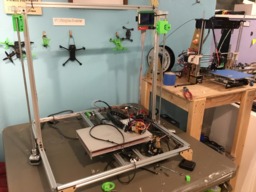

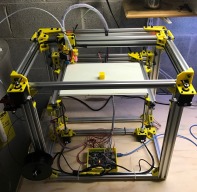

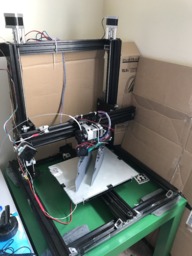

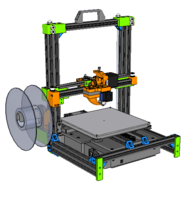

Rob's D-Bot Build

The plan is to make this a fairly stock D-Bot build. We'll see if mods start creeping in.

STEAM Machine

Simple design with a large build volume - 450x450x450

Build Author

Robert E. Nee

Views

17519

Build Author

Robert E. Nee

Views

17519

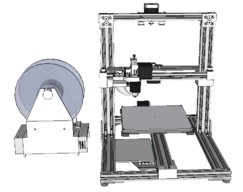

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

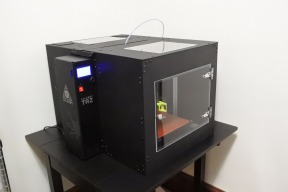

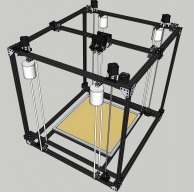

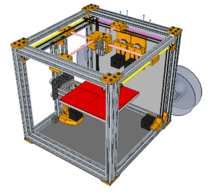

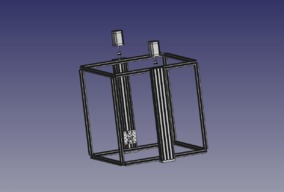

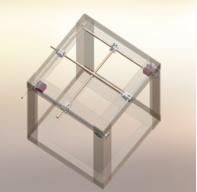

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

Peter Van Der Walt

Views

7468

Build Author

Peter Van Der Walt

Views

7468

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

recoush

Views

9315

Build Author

recoush

Views

9315

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Jonathon Duerig

Views

7221

Build Author

Jonathon Duerig

Views

7221

Chrysalis: An Enclosure for TAZ 6 3d Printers

Aluminum-framed enclosure for TAZ 6 3d Printer made with Makerlink.

Build Author

nschreiber0813

Views

5498

Build Author

nschreiber0813

Views

5498

Schreibotics Fabricator MkII

It all started after my prusa i3 build inspired me to experiment with resin 3D printers because I want to learn if they are worth it and if I can design my own printer.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

THE LINK

Views

5094

Build Author

THE LINK

Views

5094

2020 First build.

Probably cheapest DIY build youl see.

Build Author

Tomas F Uribe

Views

5351

Build Author

Tomas F Uribe

Views

5351

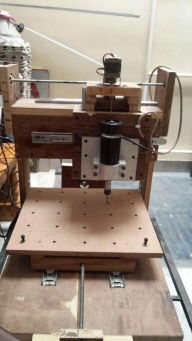

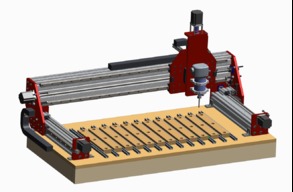

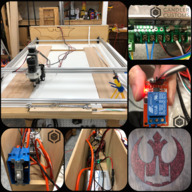

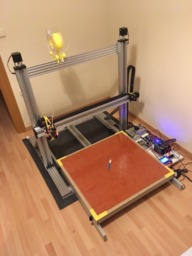

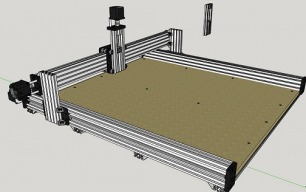

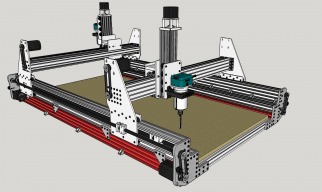

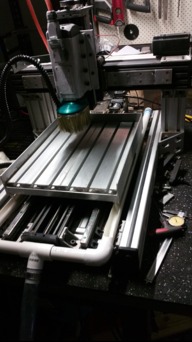

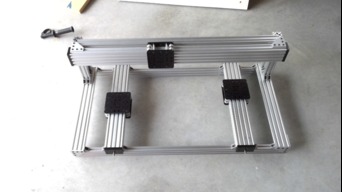

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

60W CNC Laser build

Laser CNC, 60W, didn't have one yet... have to :) This build is a retrofit of a surgical laser into a CNC.

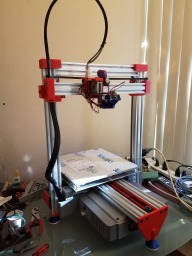

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Hisha

Views

5066

Build Author

Hisha

Views

5066

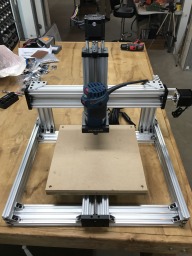

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Build Author

Huub65

Views

9320

Build Author

Huub65

Views

9320

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

evgeny156

Views

7350

Build Author

evgeny156

Views

7350

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Jens Grabner

Views

4149

Build Author

Jens Grabner

Views

4149

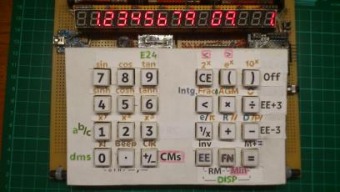

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

CNC Planning

Reusing parts to build a CNC - planning stage

Build Author

Fabio Orsi

Views

6951

Build Author

Fabio Orsi

Views

6951

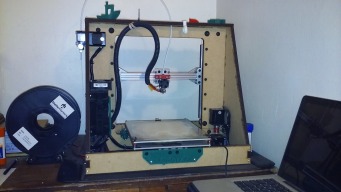

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

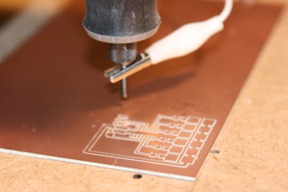

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

Build Author

megashub

Views

24313

Build Author

megashub

Views

24313

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Build Author

Karan Singh Sisodia

Views

6322

Build Author

Karan Singh Sisodia

Views

6322

My Home made CNC

Home Made CNC Router from Scrape

Build Author

islahcnc

Views

4466

Build Author

islahcnc

Views

4466

islahcnc&design

I will post soon some more details.

HUGE 3D printer build

just wanted to share my build of a huge 3d printer. It stands just over 2 meters tall and has a total print area of around 850mm x 850mm.

Build Author

JerryD

Views

5353

Build Author

JerryD

Views

5353

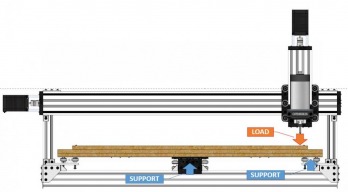

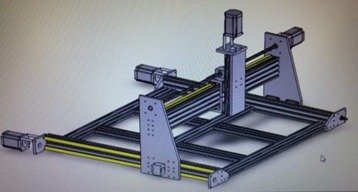

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

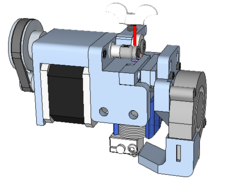

Codename: Gargoyle

A stout 3D printer build with the hopes of being able to serve as a light mill (PCB) and laser engraver

BD's C-Beam Machine CNC Router (WIP)

CNC router table based on OpenBuilds C-Beam Machine bundle.

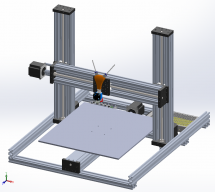

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Mark 1

My first attempt at building a CNC style machine. Overall my plan is to use the PlanetCNC breakout board and software to run the machine from a dedicated laptop/tablet.

100w Laser Cutter Build Log

I rebuild my 2 meter tall 3D printer into a 100w laser cutter

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Stock CNC Router

This is my first CNC router, so be kind on the criticism. I'm still learning. Not an engineer, and not a machinist so I am having to research and learn aspect from both of those areas of study!

OX, of the house Steel

OOZNEST Style OX machine with 3D printed panels

First CoreXY Build

First CoreXY. Simple Square build, hopes for faster movements.

Build Author

Scotty Orr

Views

11690

Build Author

Scotty Orr

Views

11690

QuorXZ: A String-driven, Core XZ Printer

The QuorXZ doesn't magically appear. It's gestation takes time, careful attention, and requires many parts. However, when it is ready, a magical, mechanical instrument is born....(and when you finally say its name, it sounds a little bit like "corks").

Strong? CNC

The goal is to have a relatively strong CNC to be able to cut alu. Working space will be around 800x350x100mm.

Modular Controller PCBs

This is a build still in the prototype stage. The initial design is being used to control a 4 axis sample change, but the PCBs when finalized will be able to be adapted as a convenient way to wire stepper (or eventually hybrid stepper) drivers to which ever controller you happen to be using. Current developments center around an Arduino Mega, although more interfaces are planned in the future. The main design centers around the use of Phoenix Connectors.

Stargeezer Vertimill

Next up will be the electronics package. My parts bins are overflowing with boards so this may be the hardest decision to make of the entire build.

First Ever Build

This is my first attempt at building my own 3d printer.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Linear Rail derivative with ball screw

basic start to design of cnc machine

Build Author

Jason Harding

Views

4100

Build Author

Jason Harding

Views

4100

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

DIY Ultimaker

This design should give the same performance as the high speed Ultimaker since it uses a similar ultra-light X/Y concept which eliminates any movement of both the X and Y motors to achieve X/Y travel.

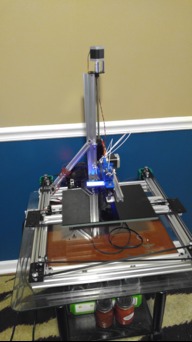

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

OB Minimill with bottom frame PSU+Drivers

All-in-one OB Minimill

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

TrueUp Bold

A beefed up modification of the TrueUp Kit project

4' by 2' Lasercutter

4foot by 2 foot, 10W El-Cheapo blue laser

Build Author

Jeremiah Guinn

Views

5841

Build Author

Jeremiah Guinn

Views

5841

OX CNC SMW3d 1500x1500

A small business idea led us here, lets see where it will go.

TrueUp LZ

A version of TrueUp using linear bearings/rods for the Z axis. This required enough modification to make a separate OpenBuilds project to avoid confusion for DIYers.

Automatic Sprayer

Automatic spray machine.

Brokkr CNC 2.0

1M C-beam xy variant

Build Author

SecretSpy711

Views

22609

Build Author

SecretSpy711

Views

22609

RigidOko

Heavily upgrading my 1200x500 Shapeoko 2... ...er, wait, scratch that... Building an all new machine, roughly the same size, that should be more rigid than a Shapeoko 3!

Student OneZ

A simplified version of the TrueUp LZ. Designed for classrooms and students

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Anthony Castelluci

Views

3247

Build Author

Anthony Castelluci

Views

3247

Simple Camera Lofted Camera Slider

Build a manual camera slider.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Tucstrlly

Views

9098

Build Author

Tucstrlly

Views

9098

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

New 2 watt laser platform

Acro based 2 watt laser platform

ivern

Toying around a concept. Inputs are welcome on whether to use lead screw or belt drive. My lead screw will be single start 500 mm lenght, 2 mm pitch and 2 mm lead. Nema 17 motors will be used. All veterans, suggestions please.

rectangles

https://www.youtube.com/watch?v=NT0N1rt3F7c it's alive

Build Author

TimVukman

Views

4319

Build Author

TimVukman

Views

4319

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

Screen Mesh Stretching

The intention of this project is so that the mesh is on the well stretched frame, and thus there is a better production of frames.

Build Author

Kyo

Views

10113

Build Author

Kyo

Views

10113

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

CNC design (parts named)

This design is previously posted in this area. I downloaded the file in order to customize as I needed. I found that the parts were not identified. I went through the design in an attempt to name the parts and identify them by location.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

patdee

Views

5120

Build Author

patdee

Views

5120

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Core XY

Just now in the planning phase of my build. Waiting for some parts to come in to see what I am going to build off of. Print area going to be close to 300x300x350. Trying to decide if I want it enclosed. I do want to print ABS... so probably so.

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Dust Shoe for Kyo's Sphinx

Dust Shoe design for a CNC router. Attaches to Chris Laidlaw's Mount design, with the DeWalt D26200 (which I think is the DWP 611 in the US).

Build Author

Lindsey Lewis

Views

8211

Build Author

Lindsey Lewis

Views

8211

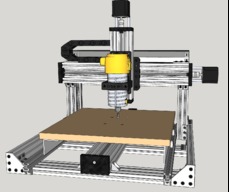

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

My 80w Laser build (1000x1000 cutting area)

This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. this laser needs to live outside

Ooznest workbee

This is my first build so I will let you know how I get on

Build Author

pedrofernandez

Views

12190

Build Author

pedrofernandez

Views

12190

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Build Author

ZacharyB

Views

5777

Build Author

ZacharyB

Views

5777

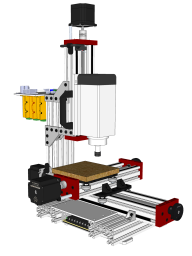

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

Dave Pyatt

Views

4525

Build Author

Dave Pyatt

Views

4525

DaveP's Homemade CNC Project

Somewhere along the line sometime around February 2017 I got the bug in my head that I needed to build a CNC router. This is where I am today...

Build Author

Terone Burgenheim

Views

2836

Build Author

Terone Burgenheim

Views

2836

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

Build Author

Terone Burgenheim

Views

6450

Build Author

Terone Burgenheim

Views

6450

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Carl van Heezik

Views

8462

Build Author

Carl van Heezik

Views

8462

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

cory stafford

Views

4790

Build Author

cory stafford

Views

4790

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

Build Author

MidnightQuads

Views

3912

Build Author

MidnightQuads

Views

3912

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

GDanger117

Views

12376

Build Author

GDanger117

Views

12376

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Lindsey Lewis

Views

9027

Build Author

Lindsey Lewis

Views

9027

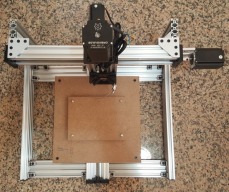

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Keith Davis

Views

5458

Build Author

Keith Davis

Views

5458

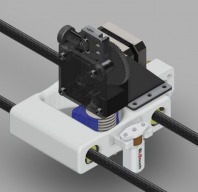

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

George Motichka

Views

3785

Build Author

George Motichka

Views

3785

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

RJ_Make

Views

6074

Build Author

RJ_Make

Views

6074

Fully Open Source Motorized Camera Slider Build Overview (OpenSlider)

This is a video were take a high level look at how I built up my version of a fully open source Motorized Camera Slider (OpenSlider)

Build Author

CandlerCustoms

Views

5575

Build Author

CandlerCustoms

Views

5575

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

Somewhat Simple Lead screw conversion for an OX CNC

Somewhat Simple Lead screw conversion for an OX CNC.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

![Acros with customizations [WIP]](https://builds.openbuilds.com/data/article_images/l/6/6329.jpg?t=1517104699)

Build Author

Sam Price

Views

5816

Build Author

Sam Price

Views

5816

Acros with customizations [WIP]

This is a work in progress ACROS build with new legs and wire tracks.

Build Author

Camvec

Views

6285

Build Author

Camvec

Views

6285

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://builds.openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)