Build List

-

Active Filters:

an

Build Author

Lasersc

Views

10487

Build Author

Lasersc

Views

10487

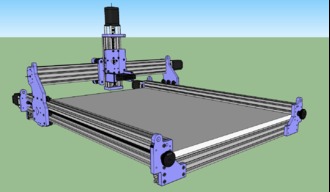

D&R Tiger Paw build combo

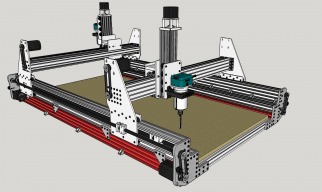

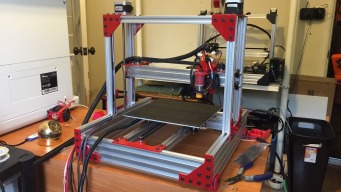

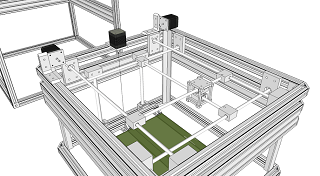

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

Lasersc

Views

5481

Build Author

Lasersc

Views

5481

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Build Author

James Evanko

Views

7340

Build Author

James Evanko

Views

7340

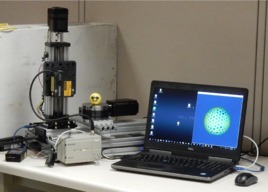

Laser Displacement Golf Ball Scanner

Getting an accurate scan of a golf ball can be difficult with general-purpose 3D scanners. This purpose-built golf ball scanner uses a very accurate Keyence LK-081 laser displacement sensor with an Open Builds linear actuator for the vertical axis and a Sherline CNC rotary table for the turntable. Scan detail is determined by the sample step size and can be set arbitrarily based on desired scan time.

Build Author

pek

Views

84499

Build Author

pek

Views

84499

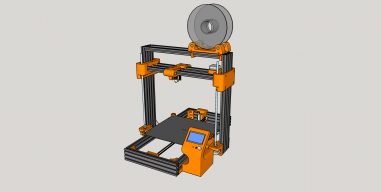

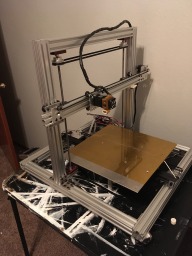

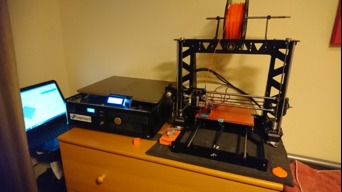

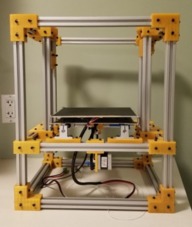

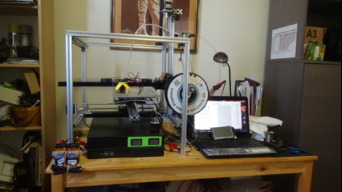

Prusa i3 Bear Upgrade V2

Stronger frame for Prusa i3 MK2(s), MK2.5 and MK3 3D printer

Build Author

Mark Carew

Views

19607

Build Author

Mark Carew

Views

19607

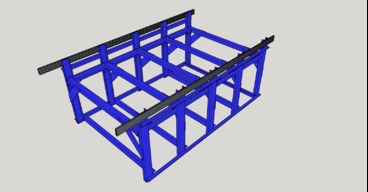

V-Slot Modular Sit/Stand Desk

In this build we put together an awesome modular stand-up or sit down desk that is perfect of any home or office.

Build Author

Mark Carew

Views

75642

Build Author

Mark Carew

Views

75642

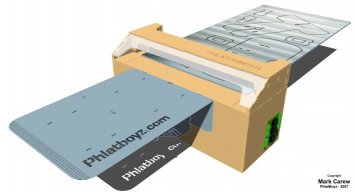

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Build Author

Ariel Yahni

Views

6674

Build Author

Ariel Yahni

Views

6674

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

Build Author

JerwanDavis

Views

6101

Build Author

JerwanDavis

Views

6101

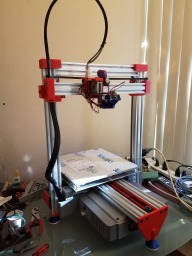

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Build Author

thinman

Views

8839

Build Author

thinman

Views

8839

Delta250

A 250x250 mm Delta Printer utilizing a Duet Wifi controller and a Titan Aero direct drive extruder.

Build Author

Cosmosteel

Views

4600

Build Author

Cosmosteel

Views

4600

Clear Acrylic Dust Shoe

Attaches router with screw clamping. Clear Skirt is 2" long or can be made longer if requested. Works well keeping dust within the chamber. It can be made to fit shapeoko, ox cnc, workbee, xcarve, 6040, laguna,piranha, millright etc. with similar setup including Bosh, Makita , dewalt 611 routers or spindles.

Build Author

CharlieShimota

Views

16262

Build Author

CharlieShimota

Views

16262

Vox Solid State

I never thought owning a CNC machine was possible until I stumbled upon the Openbuilds site. After viewing numerous builds I was drawn to the Ox by Mark Carew but ultimately decided on a build of similar design, Halloumi by Savvas. It's a C-beam design driven by Nema 23 steppers with Acme lead screws. Like Savvas I will be fabricating temporary plates to get up and running then use the machine to mill the final plates. The material I'm using for the temp plates is solid surface (Avonite).

Build Author

Hidro669

Views

3796

Build Author

Hidro669

Views

3796

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

Mark Carew

Views

6211

Build Author

Mark Carew

Views

6211

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

holographic

Views

7957

Build Author

holographic

Views

7957

Laser DIY

How i construct and create my DIY Co2 Laser cutter and engraving mashine. details will follow

Build Author

Christian James

Views

10070

Build Author

Christian James

Views

10070

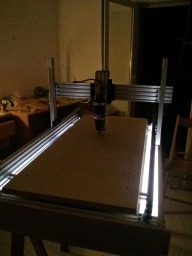

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

David Hartkop

Views

3054

Build Author

David Hartkop

Views

3054

Humanitarian Medical Instrument Sterilizer Made from RepRap Parts

Instructions to build an open-source off-grid medical instrument sterilizer that can be used by aid workers in places without reliable electrical power

Build Author

pedrofernandez

Views

10058

Build Author

pedrofernandez

Views

10058

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Build Author

Connor Mckeown

Views

6442

Build Author

Connor Mckeown

Views

6442

My Prusa Build

The process from my bought printer, to a custom home built machine

Sphinx 1050

Openbuilds 1050 Sphinx. Thank you to Mark Carew for trading me a set of plates for a spindle and PSU I was not using. Mark is a champ!

Build Author

Liam Dahler

Views

6562

Build Author

Liam Dahler

Views

6562

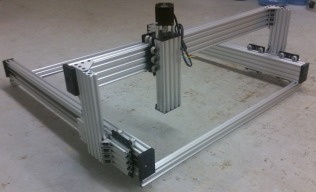

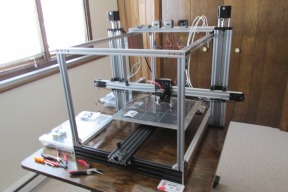

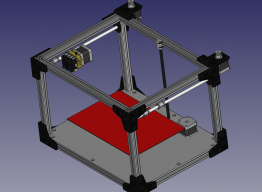

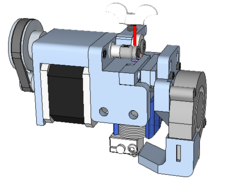

Affordable Cartesian Printer (Initial Design)

This specific build page is a collection of screenshots sampling some of my initial SolidWorks design and pictures showing physical construction of the initial design. I will be creating individual build articles as I redesign, test, and implement new aspects of the printer.

LYNX - Huge 3D printer

I'm basically building a larger version of my crappy wanhao 3d printer. My work was recycling some aluminium extrusion and it broke my heart to see such nice pieces of aluminium engineering being sent to a furnace. Mega 3d printer was born!

Build Author

Sonny Lowe

Views

34850

Build Author

Sonny Lowe

Views

34850

MakerSL MSL-5 Cantilevered 3D Printer

This is a simple cantilevered 3D Printer. It is designed around the OB V-Slot linear rails. I am trying to simplify this as much as possible, all rails will be 250mm long and only one will require cutting (it will be cut in half). The printer will use all OB wheels and gantry plates where applicable, all other plates can be either Laser Cut or 3D Printed (files will be provided for both). I am not set on electronic as of yet, but plan to use a single control board...no Arduino/Ramps control.

Build Author

rob4cnc

Views

4045

Build Author

rob4cnc

Views

4045

Rock n Roll

The Rock n Roll is built on granite, is solid as a rock, and gathers no moss. This build provides a high degree of accuracy and repeatability. Built to be strong, use redundancy, and use long lever arms to average out imperfections in the equipment. Built to go fast and light. We will use a high speed spindle, large high voltage stepper motors and small cutting heads to overwhelm the forces produced at the cutting head.

Build Author

Robert E. Nee

Views

17578

Build Author

Robert E. Nee

Views

17578

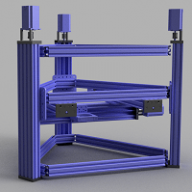

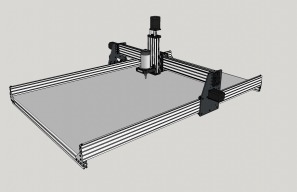

Large cartesian gantry style 3D printer

This will be a fixed bed, v-slot implemented X,Y,Z axis gantry style 3D printer.

Build Author

James Evanko

Views

4878

Build Author

James Evanko

Views

4878

Ball Trajectory Machine

Need to build a machine that accurately positions objects for processing by a computer vision algorithm? Here is an example of a machine that does that for a ball trajectory application. The black anodized V-rails work well for applications in optics and imaging where the machine needs to stay out of the limelight.

Workbee CNC 1500

Trying to build a machine of atleast 4x4ft working area. Work is in progress, hope to finish it soon

Build Author

MikieLikesIt

Views

8279

Build Author

MikieLikesIt

Views

8279

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Build Author

signzonepr

Views

13059

Build Author

signzonepr

Views

13059

HD c Beam CNC Router

24x32 Cnc Router, I used vSlot c Beam Extrusion and Wheels!

Build Author

Jones

Views

4024

Build Author

Jones

Views

4024

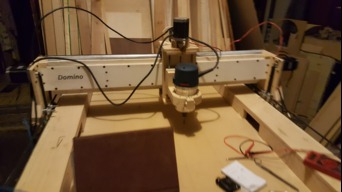

The Domino - 1.5m x 1m

DIY scratch build consisting of gas pipe, skate bearings, 12mm birch, 3/4 maple v-core ply, Nema 23's, and arduino and CNC shield with DRV8825's.

eTrueUp Glide

A TrueUp Glide modified to use 20x40 V-Slot with a 300x300 bed.

Build Author

Hilleke

Views

7891

Build Author

Hilleke

Views

7891

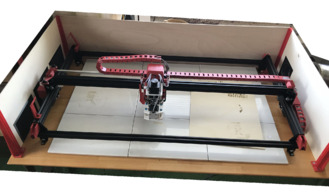

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

Build Author

Nicademus

Views

9616

Build Author

Nicademus

Views

9616

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

thehans

Views

6696

Build Author

thehans

Views

6696

Voxel OX with Helix Gear Z Transmission (single z motor)

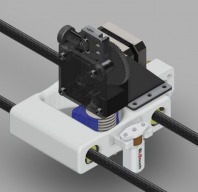

This is a modification I made to my Voxel Ox 3D Printer Z axis, which synchronizes the Z leadscrews via a shaft and helical gear transmission. It prevents the two Z leadscrew from getting out of adjustment relative to each other, and uses a single Z motor instead of two. This build is just documenting the specific changes I have made to the Z-axis, since the frame and other axes are still from the original Voxel Ox design.

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Beam

Views

11685

Build Author

Beam

Views

11685

DIY Flywheel Camera Slider

My take on a non affordable slider.

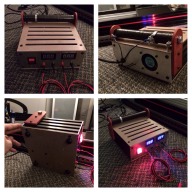

DIY anodizing power supply

How to make your own anodizing power supply on a budget

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Keith Davis

Views

5469

Build Author

Keith Davis

Views

5469

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Skyggen 3D Printer

GT2 belt-driven Cartesian 3D Printer on an OpenBuilds Extrusion gantry, developed through Autodesk Fusion 360.

Build Author

Andre Cooke

Views

17664

Build Author

Andre Cooke

Views

17664

CNC Greenland Paddle Carver build

CNC mill for carving / milling Greenland Paddles

Build Author

TimVukman

Views

4327

Build Author

TimVukman

Views

4327

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

VoS

3D Printer based upon 3d printed parts and open builds componets

32 Button Hand Pendant for the PlanetCNC Control Board

This project is for building a remote hand pendant for the Planet-CNC control board but could be adapted for many other projects. The pendant allows for machine control without being at the computer keyboard and the button functions on the pendant are defined by the user.

Build Author

Daniel.korneliussen

Views

3535

Build Author

Daniel.korneliussen

Views

3535

Reprap prusa mendel i2 Frankenstein 2018 build

Mad plumbers choice what Else can i say?

Build Author

Denis Lapratte

Views

4601

Build Author

Denis Lapratte

Views

4601

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

bpatterson42

Views

3597

Build Author

bpatterson42

Views

3597

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

GDanger117

Views

12415

Build Author

GDanger117

Views

12415

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Bud Griffin

Views

11660

Build Author

Bud Griffin

Views

11660

BF3D OX (Big Freakin' 3D OX)

This is my latest printer build. The second printer I've built using V-Slot.

Build Author

Ronald van Arkel

Views

16653

Build Author

Ronald van Arkel

Views

16653

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

William Niedermeyer

Views

19705

Build Author

William Niedermeyer

Views

19705

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

DaveStewart

Views

6154

Build Author

DaveStewart

Views

6154

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Build Author

CubeSpawn

Views

19799

Build Author

CubeSpawn

Views

19799

CubeSpawn Ultimaker 3D Printer Module

This 3D printer is an implementation of the Ultimaker 3D printer Using the Modular approach, many of the parts from the CubeSpawn 3 axis mill translate straight across into this design, so adding new concepts should go quicker

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Build Author

pek

Views

6516

Build Author

pek

Views

6516

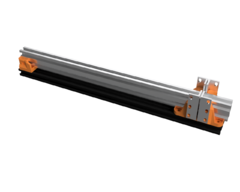

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Anthony Castelluci

Views

3253

Build Author

Anthony Castelluci

Views

3253

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Automatic Sprayer

Automatic spray machine.

Build Author

PaulS

Views

20663

Build Author

PaulS

Views

20663

UltiFaker 2 Go

This is a breakdown of how I designed the UltiFaker 2 Go as well as how I machined and assembled it. I'll include a complete BOM and all of the drawings and prices.

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

Build Author

Jason Harding

Views

4113

Build Author

Jason Harding

Views

4113

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Build Author

francesco pollina

Views

7167

Build Author

francesco pollina

Views

7167

FFF 3D printer 2x2x2m

The 3D printer will be able to print 2x2x2m components and not just in PLA or ABS. It's not just a DIY printer but I'm trying to apply engineering formulas to make it. I'm going to apply the state of art for 3D printing and scannering existing.

C Beam CNC+Laser

You will be following the assembly of the mechanical kit and how i integrate the electronics into the final build.

Norm Inverted - Cartesian

As a tinkerer and hobbyist I need a reliable quality printer on a budget... Meaning I'm not looking to buy a: Prusa, Zortrax or LulzBot because of the added cost their marketing adds. I can definitely build a machine of hopefully equal quality at a lower cost that is not impacted by the marked-up priced from a large reputable manufacturer. I will need to dedicate time and more time for design shakedowns to ensure I produce a quality machine. Bare with me on this build... Thanks!

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

Pol Feliu

Views

9290

Build Author

Pol Feliu

Views

9290

Batxillerat Research Project: Design and construction of a CNC

I'm working on a cartesian cnc router for my school research project

The Hoss

The purpose of this build is to create a simple, strong modular build that is rugged enough to cut out some of the softer metals along with wood and plastics. Using basic parts like the universal plates, t-nuts and v- wheels coupled with the strength of C-Beam I am sure this will deliever the desired results!!

Build Author

Justin Butler

Views

9286

Build Author

Justin Butler

Views

9286

My Belt & Pinion Drive CNC Router

My CNC Router design and inspiration came from the Routy CNC project. I modified some of the aspects of the Routy build, but left the original XY dimensions intact. The build has been very enjoyable thus far and am nearing completion of all wiring in preparation for my first test run!

Kool Bot

Mid range build.

Build Author

evgeny156

Views

7361

Build Author

evgeny156

Views

7361

3D Printer on Prusa architecture with best parts available

Wanna quet an nice looking device done by my hands

Build Author

Steven Sampson

Views

10953

Build Author

Steven Sampson

Views

10953

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

mikev

Views

8615

Build Author

mikev

Views

8615

C-Beam Evolution MkII

The C-Beam Evolution is an evolving machine. The MkII is inspired by Kyo's C-Beam Spinx but currently uses my own design of plates made of 8mm acrylic (X-axis ends) and 6mm polycarbonate (Y axis ends). The plates were made on the MkI but I hope to be able to make 6mm aluminium plates on the MkII for the MkIII.

CO2 Tube life expectancy experiment - Sponsored in part by Openbuilds

Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

Build Author

J-Wahl Dezign

Views

9164

Build Author

J-Wahl Dezign

Views

9164

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

eddyg

Views

5020

Build Author

eddyg

Views

5020

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

Build Author

Peter Van Der Walt

Views

7486

Build Author

Peter Van Der Walt

Views

7486

The Almost Perfect 3 Way Mitre (with Angle Corner Connectors)

A quick and easy way to make a 3-way mitered corner using Corner Connectors

Build Author

Rich Bowen

Views

3862

Build Author

Rich Bowen

Views

3862

WannaBe CNC - First time design and build

Design Change - Version 2.0 has a smaller foot print, custom gantry supports, and front and back covers. I will use standard V-Slot for gantry supports leaving me enough travel to manufacture the customer supports with this machine when completed. then update to final build. I also plan to install the controller into the front cover and power supply into the back cover. Should be nice and tidy.

Build Author

3D Meister

Views

5562

Build Author

3D Meister

Views

5562

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Talos3D

In Greek mythology, Talos (/ˈteɪlɒs/;[1] Greek: Τάλως, Talōs) was a giant man of bronze made by Hephaestus (the Greek god of fire, metalworking, craftsmen and blacksmiths) who protected Europa in Crete from pirates and invaders. He circled the island's shores three times daily.

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

blackcat3d printer

in construction ! chassis vslot 80x20 & 20x20 & 60x80 (Z) home made plates with whells polycarbonate build volume environ, 750x300x200 2 ed3d v6 volcano nozzles 0.8mm & 0.6 + titan extrudeurs rumba bord + auto levelling ip camera home made heat bed aluminium 5mm + glass + heat air chamber 6 doors plexiglass......

Build Author

Makerparts

Views

7734

Build Author

Makerparts

Views

7734

DIY Multi Row Nodal Point Spherical Panorama Head

DIY Pano Head

Large 3D printer 12"x12"x12" with heated bed

I want to have a printer to support senior projects. Also working on supporting 3D printing needs in the local community.

betterBot

This is going to be a more or less detailed how to build BetterBot. Pictures and more (decent) text are to be added.

Build Author

TouchPadKing

Views

5120

Build Author

TouchPadKing

Views

5120

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

dodgenet

Views

6621

Build Author

dodgenet

Views

6621

Budget 1500mm OpenBuilds V-Slot Deltabot Build

This 1500mm tall Delta is a work in progress. The triangle corners are water jetted from 1" 6061 Aluminum, and are welded to 1" square tubing. The 1500mm OpenBuilds 20x20 V-Slot extrusions are held into the corner brackets by two stainless steel set screws per bracket. This printer will need to be reinforced with wall brackets due to the combination of height/materials.

Stainless OX kit

This is a 1500 X 1500 Stainless OX kit build, by a cnc novice. It is the first cnc machine i have ovned and build I got this kit from http://makersupplies.dk/20-ox-cnc-kits

Build Author

Ken376

Views

3772

Build Author

Ken376

Views

3772

Welded project cnc first try

Kind of hard to see in this pic now lining up drive s and finishing framework

Linear Rail for Dobot Magician

This is a simpel build of a Linear rail for the Dobot Magician.

Build Author

Larry_AK

Views

10294

Build Author

Larry_AK

Views

10294

MUSK-OX

Pretty much a straight OPENBUILDS OX that slowly getting some modifications.

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

CBeam OX

i wanted to use both the ox and the C beam C beam for the gantry because its stronger i also made the gantry 20 mm higher so i can cut thinker material i will maybe later go to rack& pinion on the 1500 mm Y axes also instead of the V wheels i will maybe go to hiwin in the furture

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

Cartesian CNC router

This project has been a steep learning curve in an unfamiliar area for me. It has been a very rewarding experience and has opened up so many more possibilities to pursue in the future.

Controlbox for a CNC Router

A Controlbox for my CNC-Router, containing stepper-drivers, Planet-CNC MK3 Controller and a Controlpanel with joysticks.

Nox 1500mm x 1500mm C-Beam

C-Beam build using a double C-Beam for the X axis. 1500mm x 1500mm

Schematix OX metal build

OX metal build from an noob

Reborn as the Soccer Pitch for our Robot Spider Soccer game - Robotics/Maker Club Teaching Cart

The Soccer Pitch for our Robot Spider Soccer game